Method for manufacturing nitrile rubber medical gloves

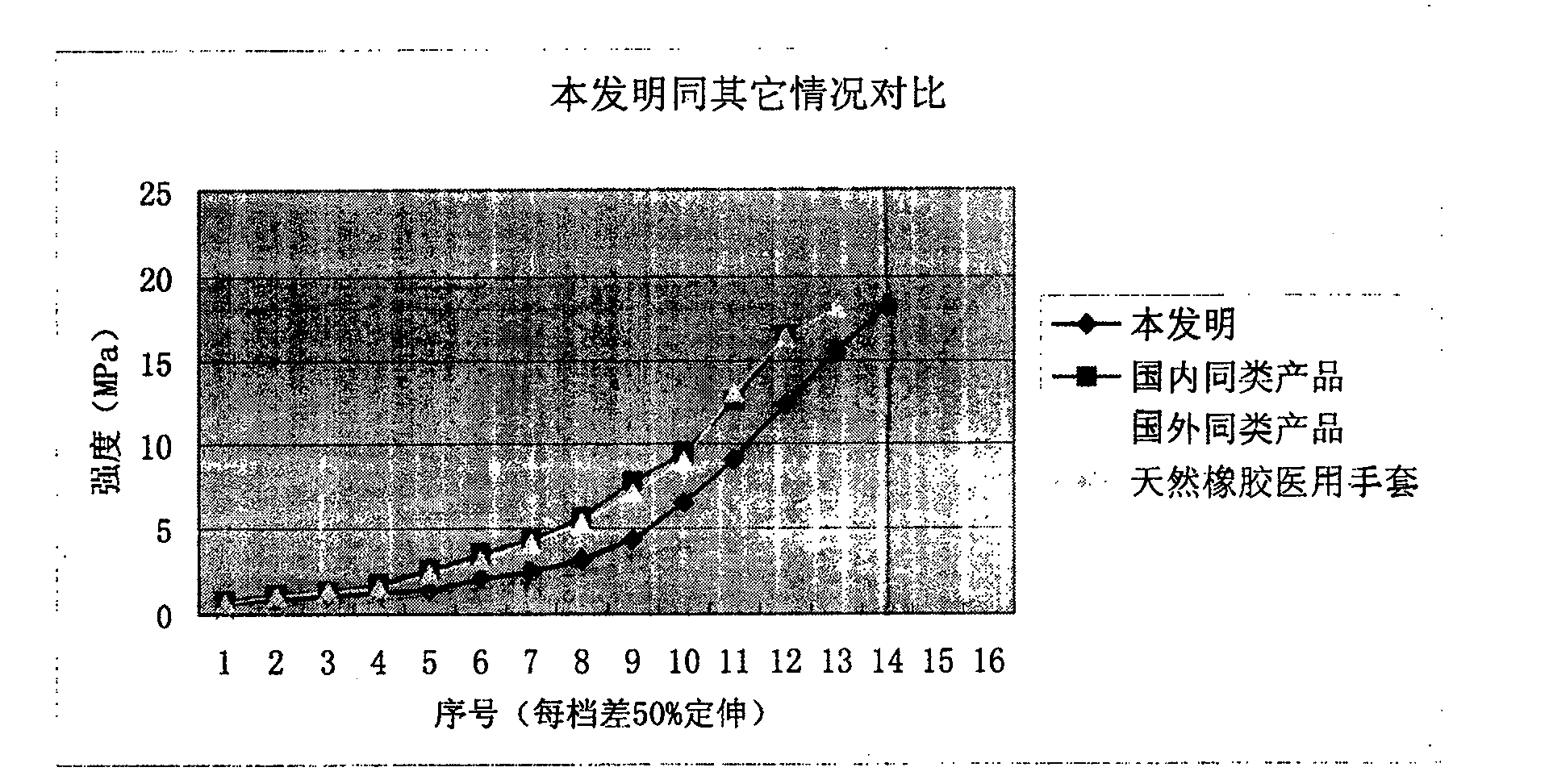

A kind of nitrile rubber, the technology of manufacturing method, applied in the direction of application, household components, household appliances, etc., can solve the problems that can only be used for medical examination, high constant tensile stress, low softness, etc., achieve good isolation, fixed Low tensile stress and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Preparation of dispersants and related reagents

[0016] The preparation of protective agent casein, diffusing agent NNO, stabilizer potassium hydroxide, surfactant and emulsifier is carried out according to the conventional natural rubber latex glove preparation method, and the general concentration requirements are:

[0017] A. Protective agent casein and diffusing agent NNO are 10-20%,

[0018] B. The concentration of stabilizers, emulsifiers and surfactants is 20%-25%.

[0019] 2. Dispersion Preparation

[0020] The main dispersions used in this system are: sulfur (S), zinc oxide (ZnO), accelerator ZDC, accelerator BZ, whitening agent TiO2, etc.

[0021] The preparation of the dispersion requires grinding with a ball mill or a sand mill, in which sulfur (S) must be ball milled, and the ball milling time is generally required to be more than 72 hours, and the speed of the ball mill tank is generally 100±10 rpm.

[0022] Other materials can be ground with a sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com