Foodstuff sanitation-stage enhancement type elastic waterstop material for civil engineering deformation joint

A technology of food sanitation and civil engineering, which is applied in the field of hydraulic materials and rubber products, can solve problems such as different compositions, unspecified waterstops, and natural hazards, so as to improve elasticity, improve waterstop effect, and improve mechanics The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

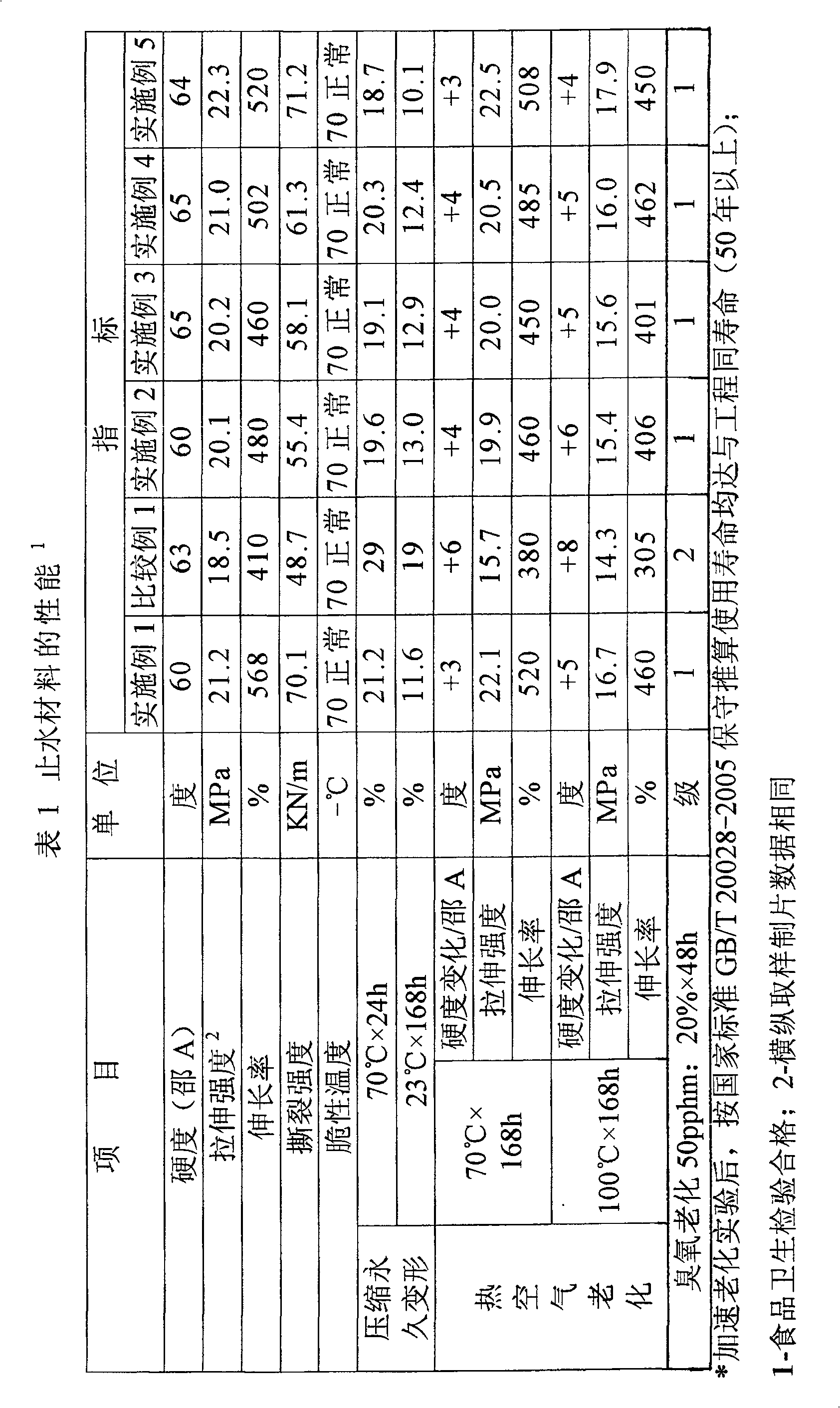

Examples

Embodiment 1

[0022] Roll 100 parts of EPDM raw rubber on an open mill, mix 2 parts of T-ZnOw, 50 parts of CB, 1 part of SA and 20 parts of liquid EPDM operating oil and compound accelerator 0.5 parts of M+1.5 parts of TMTD and 1.5 parts Part S is added in sequence and kneaded evenly for the next tablet. Then, it is vulcanized on a flat vulcanizer (160°C×15min×15MPa), and the film is removed.

Embodiment 2

[0026] Roll 100 parts of EPDM raw rubber on an open mill, and mix 1 part of T-ZnOw, 45 parts of CB, 0.5 parts of SA and 5 parts of naphthenic oil operating oil and composite accelerator 3 parts of M+1 part of TMTD and 0.5 part of S was added in sequence and kneaded evenly. Then, it is vulcanized on a flat vulcanizer (160°C×15min×15MPa), and the film is removed.

Embodiment 3

[0028] Roll 100 parts of EPDM raw rubber on the open mill, mix 10 parts of T-ZnOw, 80 parts of CB, 3 parts of SA and 30 parts of liquid EPDM operating oil and compound accelerator 0.5 parts of M+1.5 parts of CZ and 1.5 parts Part S is added in sequence and kneaded evenly for the next tablet. Then, it is vulcanized on a flat vulcanizer (160°C×15min×15MPa), and the film is removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com