Method and system unit for flue gas desulfurization and wastewater treatment

A technology for desulfurization wastewater and treatment methods, which is applied in dehydration/drying/concentrated sludge treatment, water/sewage treatment, neutralized water/sewage treatment, etc., and can solve complex evaporation treatment equipment, no root cause of pollution, high energy consumption, etc. problems, to achieve the effect of simple and convenient operation, avoiding special equipment, and economical investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The flue gas desulfurization wastewater treatment method comprises the following steps:

[0044] 1. Alkaline treatment with calcium hydroxide, the pH value is about 9.5;

[0045] 2. Add organic sulfide, the amount added is 50mg / L;

[0046] 3. Added coagulant aluminum sulfate (30mg / L), and 0.1% aqueous solution flocculant polyacrylamide (8mg / L);

[0047] 4. Carry out water clarification and sludge concentration, and separate suspended solids from wastewater;

[0048] 5. Dewater the concentrated mud.

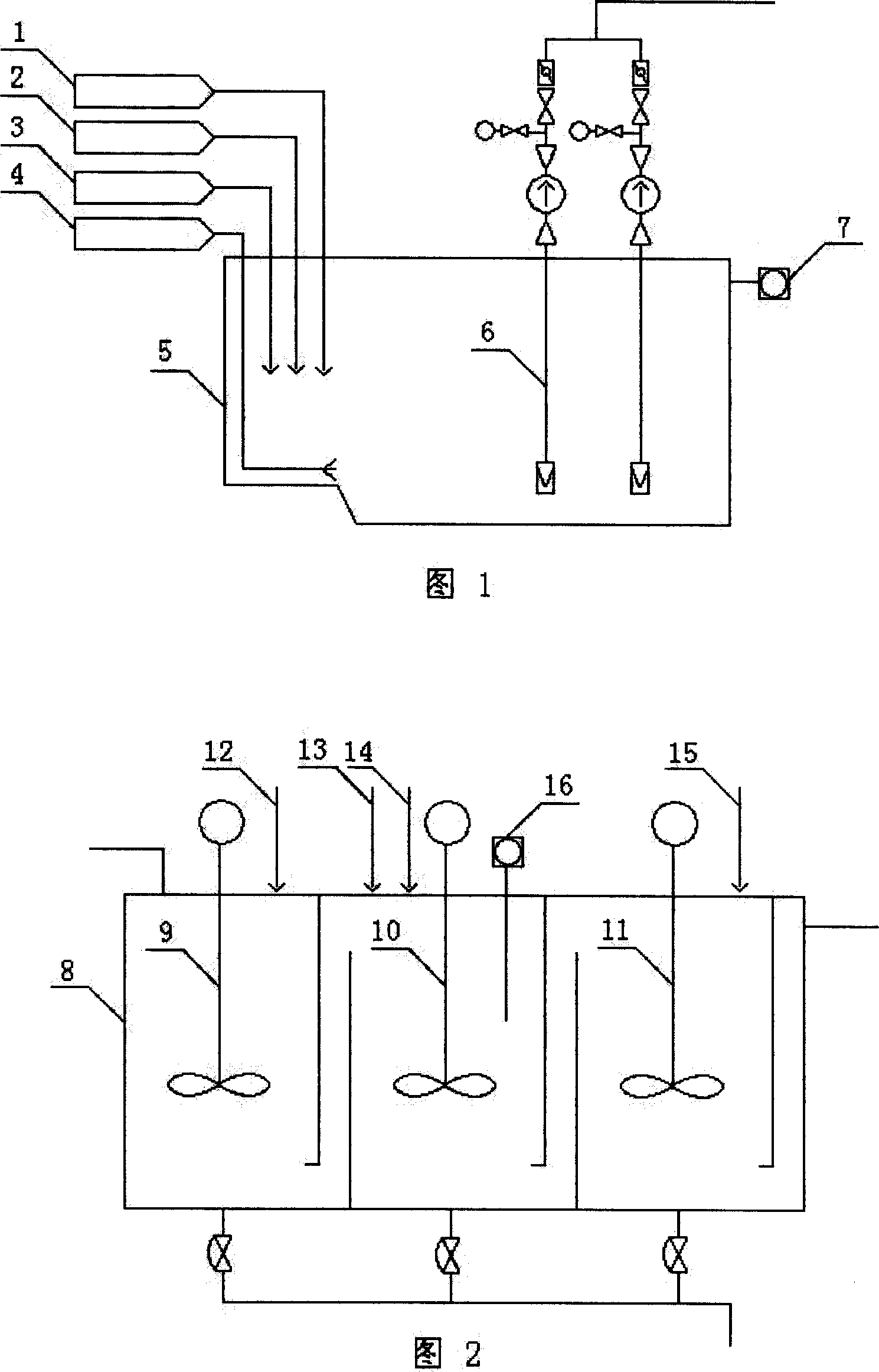

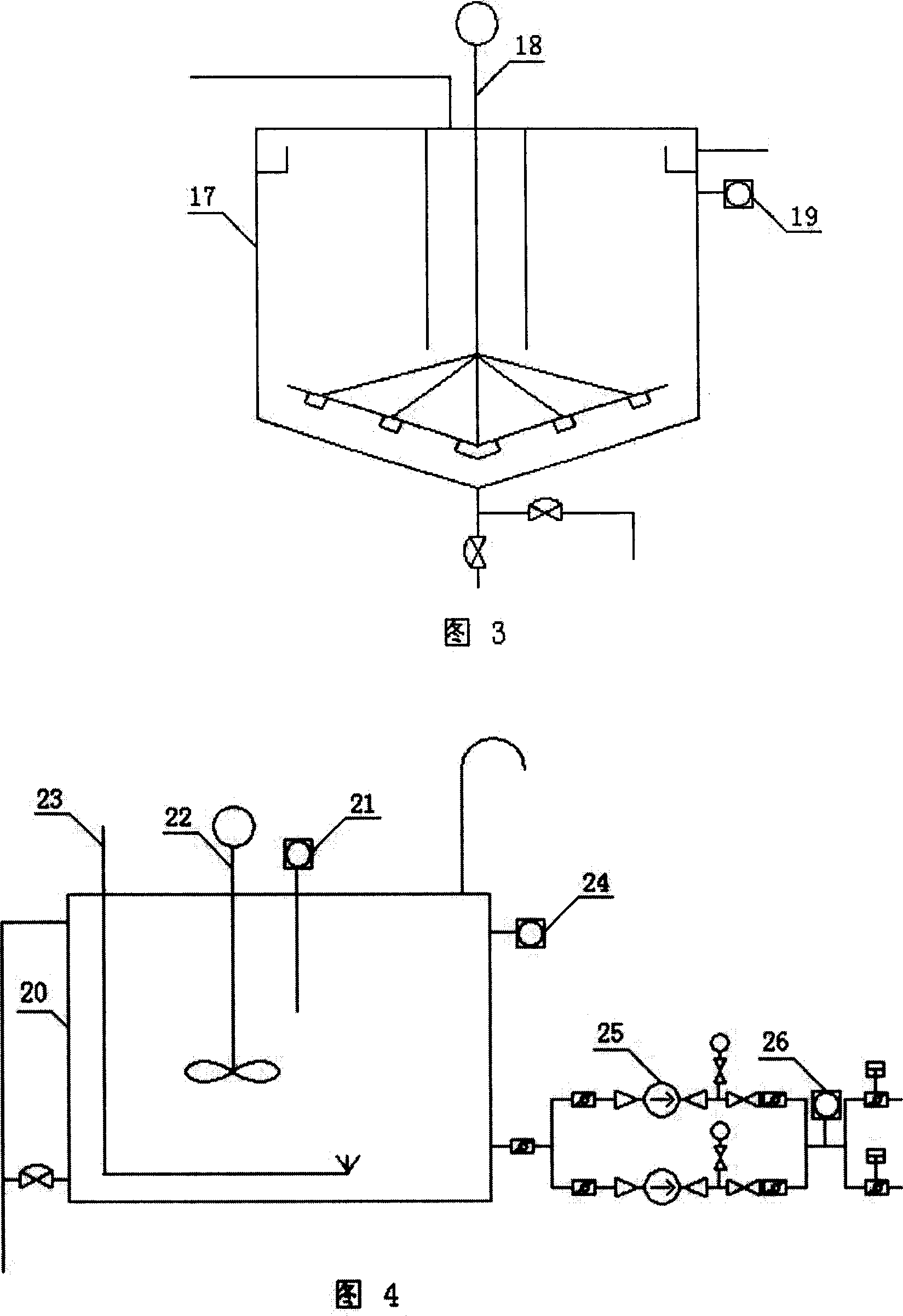

[0049] The flue gas desulfurization wastewater treatment system device of the present invention is shown in Fig. 1 to Fig. 4. The system device is composed of a wastewater buffer tank 5, a neutralization / reaction / flocculation tank 8, a clarification / concentration tank 17, and a water outlet tank 20 connected in series through pipelines.

[0050] The wastewater buffer pool is shown in Figure 1. The desulfurization wastewater 1 first flows into the wastewater buffer pool 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com