Method for mensurating content of niobium by method of separating weights of sodium sulfite - tannic acid

A technology of sodium sulfite and tannic acid, which is applied in the preparation of test samples, the use of material absorption weighing, color/spectral characteristic measurement, etc., can solve the problems of expensive instruments, low productivity, large limitations, etc., and reach the determination range Improvement, low cost, and limited limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A kind of sodium sulfite-tannin separation gravimetry method for measuring niobium content comprises the following steps:

[0012] (a) Place the sample in a beaker and dissolve it completely with nitric acid and hydrofluoric acid until the sample is completely dissolved, then add perchloric acid, and use perchloric acid fumes to drive away the silicon contained in the sample;

[0013] (b) Add sodium sulfite and tannic acid and heat to boil to hydrolyze niobium and precipitate and separate; filter and wash the precipitate, put it together with the filter paper in the original beaker, add nitric acid and perchloric acid to destroy the filter paper, then add sulfuric acid, and heat until smoking , after dissolving the produced precipitate, add sodium sulfite and tannic acid again, heat and boil to hydrolyze the niobium and precipitate and separate it, and weigh the mass of niobium pentoxide after ashing and burning;

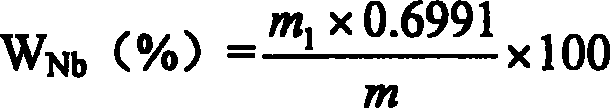

[0014] (c) Calculate the mass fraction of niobium eleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com