Method of preparing high-purity high-dispersion magnesium hydroxide fire retardant

A magnesium hydroxide, high-dispersion technology, applied in the direction of fire-resistant coatings, etc., can solve the problems of low product purity, large product particle size, and low added value, and achieve the effects of improving production efficiency, improving purity, and narrowing the distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

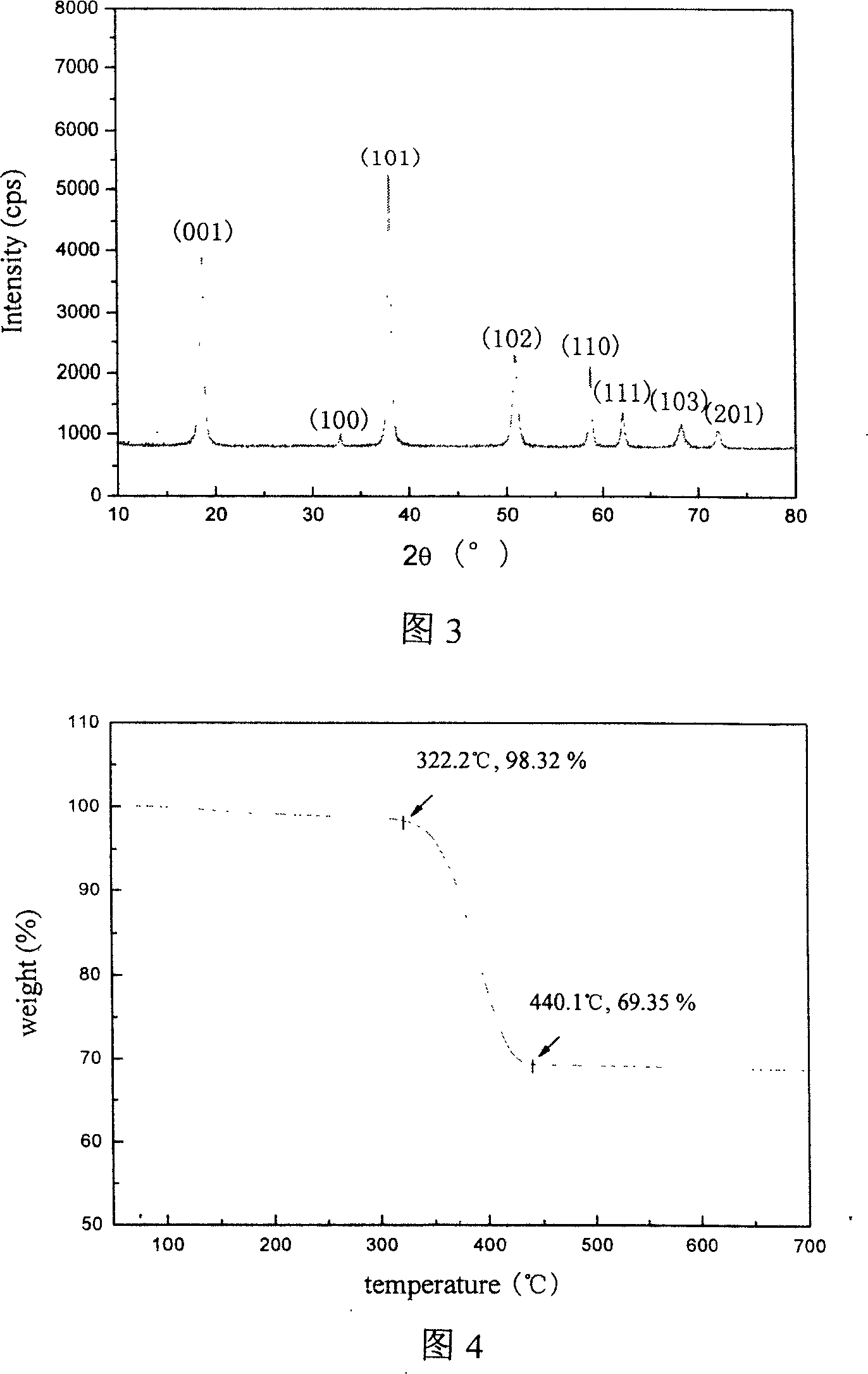

[0026] A preparation method of high-purity and high-dispersion magnesium hydroxide flame retardant, comprising the following steps:

[0027] The brine is mixed with acetone to prepare a mother liquor with a magnesium chloride concentration of 0.5 mol / L, then ammonia water is added to react to obtain a slurry, the slurry is filtered, washed, and dried to obtain magnesium hydroxide powder.

[0028] Described bittern is refined bittern, considering that the raw material directly used is salt lake bittern, method is at first salt lake bittern is dissolved in water (preferably distilled water), adds a small amount of H 2 o 2 Oxidize the impurity ions therein, adjust the pH value to 6.5, and filter after standing for 3 hours to obtain refined brine.

[0029] The refined brine is mixed with acetone to prepare a mother liquor with a magnesium chloride concentration of 0.5 mol / L. In the prepared mother liquor, acetone accounts for 5% by volume of the mother liquor, the temperature is ...

Embodiment 2

[0033] A preparation method of high-purity and high-dispersion magnesium hydroxide flame retardant, comprising the following steps:

[0034] Mix brine and acetone to prepare a mother liquor with a magnesium chloride concentration of 3.0 mol / L, then add ammonia water to react to obtain a slurry, filter, wash, and dry the slurry to obtain magnesium hydroxide powder.

[0035] Described bittern is refined bittern, considering that the raw material directly used is salt lake bittern, method is at first salt lake bittern is dissolved in water (preferably distilled water), adds a small amount of H 2 o 2 Oxidize the impurity ions therein, adjust the pH value to 7.5, and filter after standing for 10 hours to obtain refined brine.

[0036] The refined brine is mixed with acetone to prepare a mother liquor with a magnesium chloride concentration of 3.0 mol / L. In the prepared mother liquor, acetone accounts for 50% of the mother liquor by volume. The temperature is controlled at 35° C. a...

Embodiment 3

[0040] A preparation method of high-purity and high-dispersion magnesium hydroxide flame retardant, comprising the following steps:

[0041] Mix brine and acetone to prepare mother liquor with a concentration of magnesium chloride of 2.0 mol / L, then add ammonia water to react to obtain slurry, filter, wash, and dry the slurry to obtain magnesium hydroxide powder.

[0042] Described bittern is refined bittern, considering that the raw material directly used is salt lake bittern, method is at first salt lake bittern is dissolved in water (preferably distilled water), adds a small amount of H 2 o 2 Oxidize the impurities therein, adjust the pH value to 7, and filter after standing for 5 hours to obtain refined brine.

[0043] The refined brine is mixed with acetone to prepare a mother liquor with a concentration of magnesium chloride of 2.0 mol / L. In the prepared mother liquor, acetone accounts for 60% of the mother liquor by volume. The temperature is controlled at 25° C. and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com