Device and method for preparing aniline by nitrobenzene hydrogenation

A technology for preparing nitrobenzene and aniline, which is applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of easy deactivation of catalysts, difficult temperature control, low safety, etc., and achieves a deactivation trend. The effect of slowing down, reducing production costs, and operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

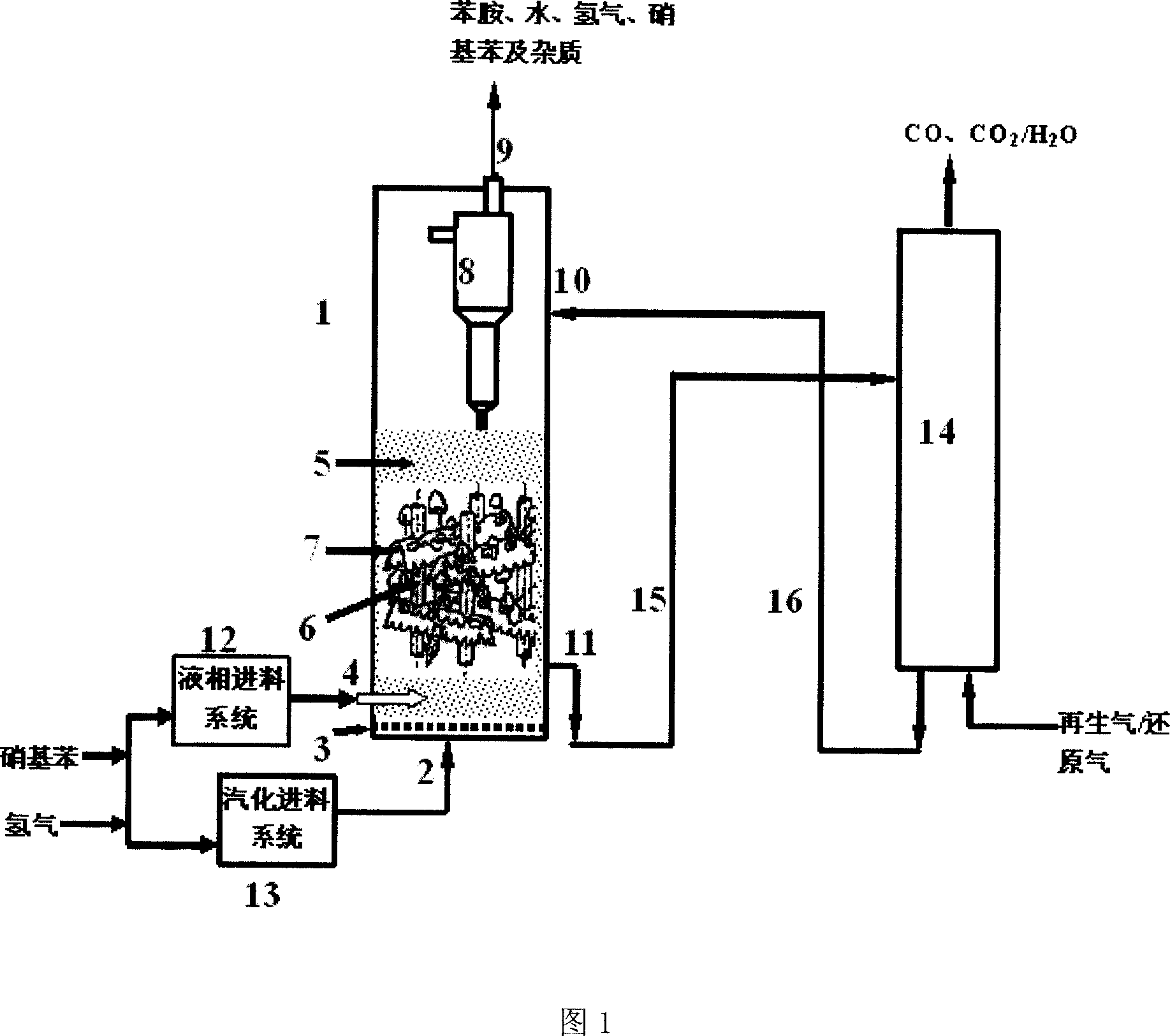

Embodiment 1

[0046] The gas inlet (2), gas distributor (3), heat exchange tube (10), gas-liquid double-flow nozzle (4), heat exchange tube (6), component (7), catalyst inlet (10), catalyst outlet (11), the cyclone separator (8) and the gas outlet (9) are sequentially connected with the cylinder wall of the fluidized bed (1) to form a complete fluidized bed (1). Wherein, the distance between the gas distributor (3) and the gas-liquid dual-flow nozzle (4) is 0.1 times the diameter of the fluidized bed. Four gas-liquid double-flow nozzles are uniformly distributed on the cylinder wall of the fluidized bed and extend into the fluidized bed.

[0047] The hydrogen and nitrobenzene pipelines of the nitrobenzene liquid-phase feeding system (12) are respectively connected to the gas pipeline and the liquid pipeline of the gas-liquid dual-flow nozzle (4). The nitrobenzene high-temperature vaporization feeding system (13) is connected with the fluidized bed gas inlet (2) and the gas distributor (3)....

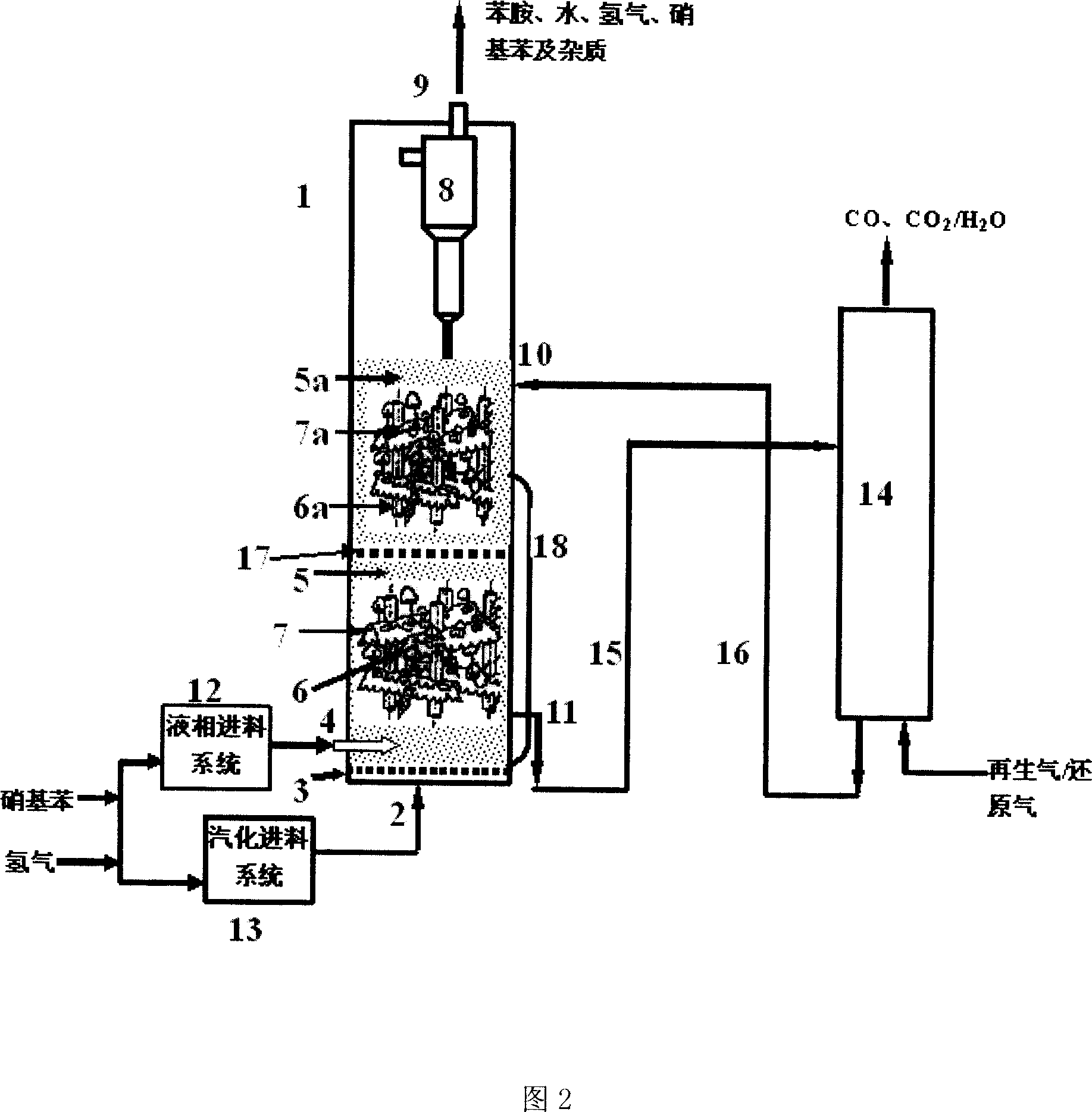

Embodiment 2

[0052] Gas inlet (2), gas distributor (3), heat exchange tube (10), gas-liquid double-flow nozzle (4), heat exchange tube (6, 6a), components (7, 7a), transverse porous distribution plate (17), transverse porous distribution plate (18), catalyst inlet (10), catalyst outlet (11), cyclone separator (8) and gas outlet (9) are connected to the cylinder wall of fluidized bed (1) successively, constitute Complete two-stage fluidized bed (1). Wherein, the distance between the gas distributor (3) and the gas-liquid dual-flow nozzle (4) is one time of the diameter of the fluidized bed. Eight gas-liquid double-flow nozzles are uniformly distributed on the cylinder wall of the fluidized bed and extend into the fluidized bed.

[0053]The hydrogen and nitrobenzene pipelines of the nitrobenzene liquid-phase feeding system (12) are respectively connected to the gas pipeline and the liquid pipeline of the gas-liquid dual-flow nozzle (4). The nitrobenzene high-temperature vaporization feedin...

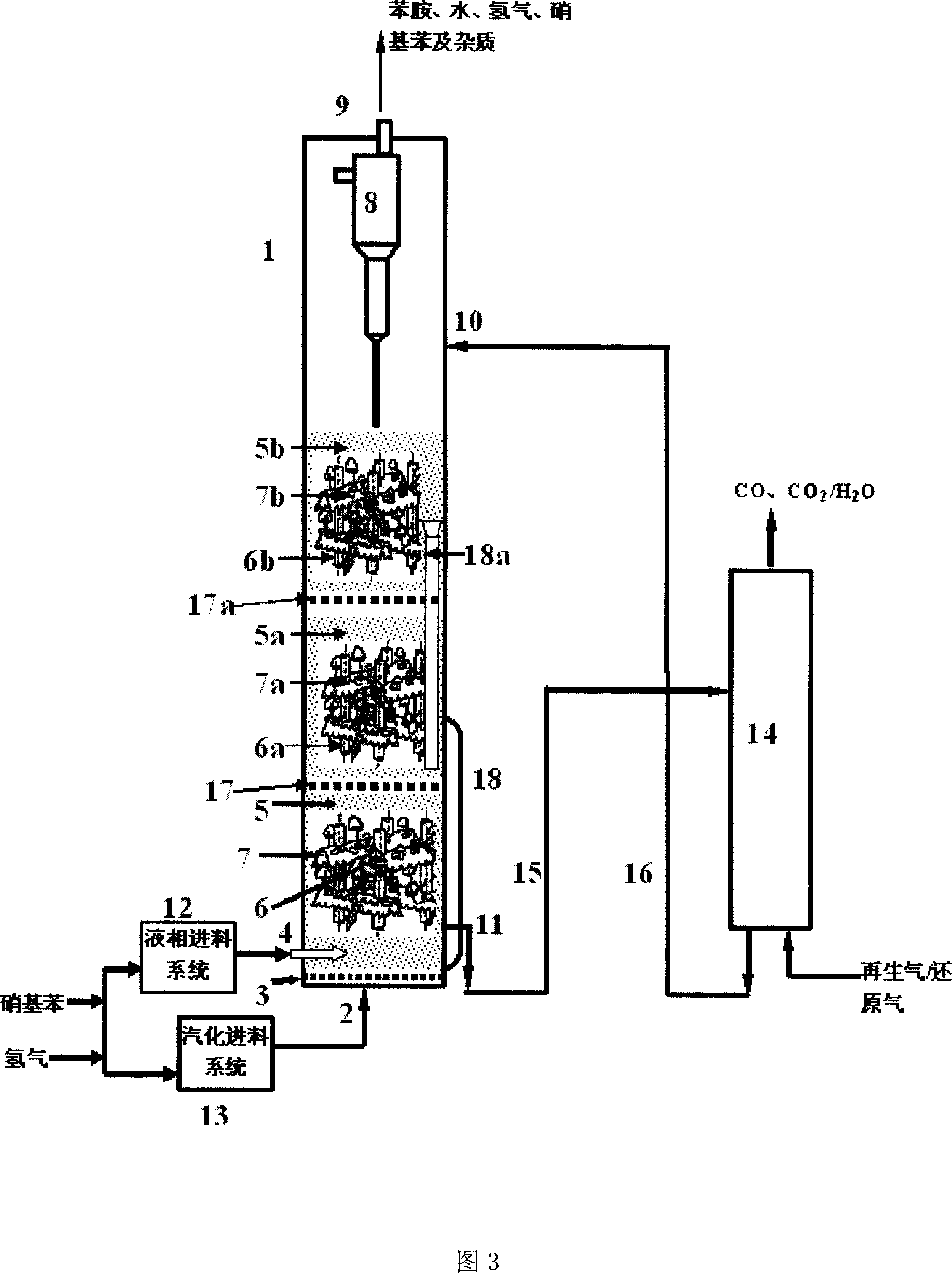

Embodiment 3

[0058] The gas inlet (2), gas distributor (3), heat exchange tube (10), gas-liquid dual-flow nozzle (4), heat exchange tube (6, 6a, 6b), components (7, 7a, 7b), Horizontal porous distribution plate (17, 17a), overflow pipe (18, 18a), catalyst inlet (10), catalyst outlet (11), cyclone separator (8) and gas outlet (9) are sequentially connected with fluidized bed (1 ) are connected to each other to form a complete three-stage fluidized bed (1). Wherein, the distance between the gas distributor (3) and the gas-liquid dual-flow nozzle (4) is 0.5 times the diameter of the fluidized bed. 16 gas-liquid double-flow nozzles are uniformly distributed on the cylinder wall circumference of the fluidized bed and extend into the fluidized bed.

[0059] The hydrogen and nitrobenzene pipelines of the nitrobenzene liquid-phase feeding system (12) are respectively connected to the gas pipeline and the liquid pipeline of the gas-liquid dual-flow nozzle (4). The nitrobenzene high-temperature va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com