Zhenqi dripping pill for strengthening resistance

A technology of Zhenqi Fuzheng and dripping pills, which is applied in the direction of pill delivery, plant raw materials, digestive system, etc., can solve the problems of affecting the effect of treatment, low bioavailability, low dissolution rate, etc., to improve bioavailability, dissolution and Accelerated absorption and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 1. Preparation of the medicinal extract: take the two medicinal materials of Astragalus and Ligustrum lucidum to decoct three times, combine the decoction and filter, concentrate under reduced pressure, and spray-dried to obtain a dry extract powder.

[0031]2. Matrix: polyethylene glycol 4000, polyethylene glycol 6000, polyethylene glycol 4000 + polyethylene glycol 6000.

[0032] 3. Proportion: Take g or kg as the unit, in parts by weight, drug extract: matrix=1:1~1:3.

[0033] 4. Use a water bath, an oil bath or other heating methods to heat the mixture until a molten liquid and / or emulsion and / or suspension containing the drug extract and the matrix are obtained, and mix well.

[0034] 5. Using a special dropping pill machine, pre-set the required drop pill specifications, and adjust the temperature control system of the dropping pill machine to heat and maintain the temperature of the dripping pill machine at 50℃~90℃. The temperature cools and forms a temperature gradie...

example 1

[0038] Example 1: Choose different substrates, different ratios of dry powder and substrate, and choose different dripper temperatures for the prescription test

[0039] Experimental design: In order to observe the following conditions: 1. Choose different substrates, 2. Choose different ratios for the same substrate, 3. Choose different low head temperatures for the same substrate and the same ratio, to formulate the effects on the products involved in the present invention, respectively Polyethylene glycol-4000, polyethylene glycol 6000, polyethylene glycol 4000+polyethylene glycol 6000 and other bases are mixed with the raw material powder, respectively according to the raw material dry powder: matrix=1:1.5 / 1:2 / 1:2.5 The proportions of the others are in accordance with the conditions given in the [Specific implementation], using electric heating to heat the raw and auxiliary materials prepared in each group to a molten state, and using a dedicated dropping pill machine to adjus...

example 2

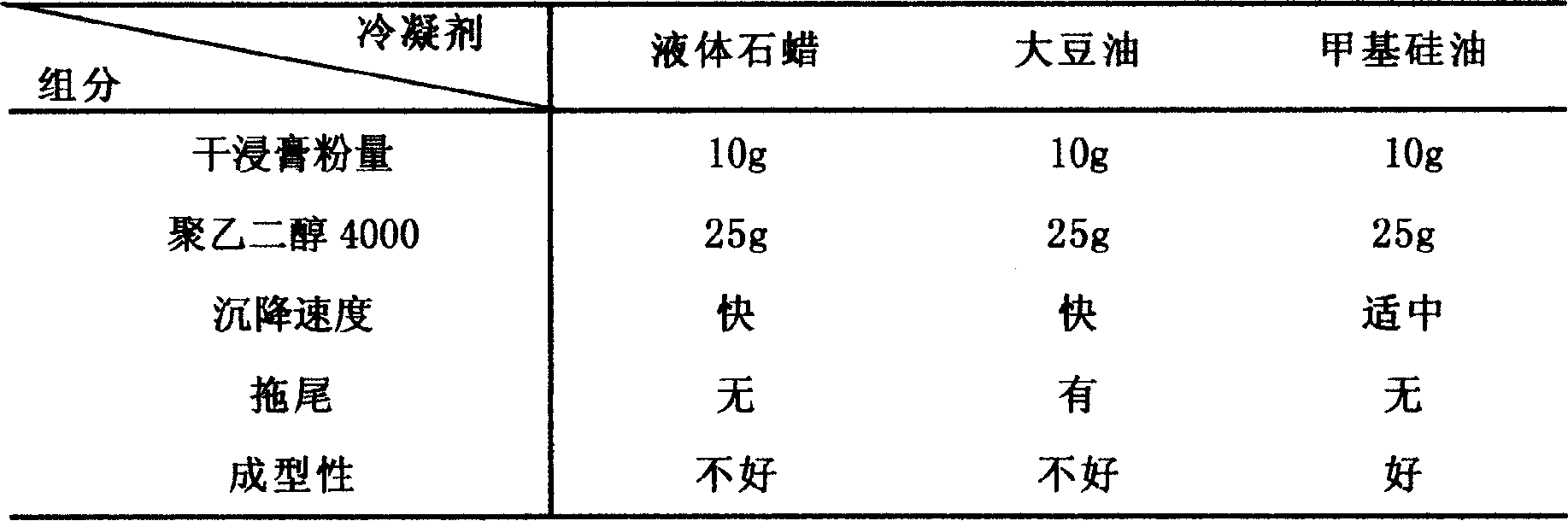

[0040] Example 2: Test of choosing different condensing agents in the preparation process

[0041] Experimental design: In order to observe the influence of different condensing agents selected during the preparation process on the products involved in the present invention, liquid paraffin, soybean oil, and methyl silicone oil were used as condensing agents, and the others were all in accordance with the conditions given in [Specific embodiments]. The matrix is made of polyethylene glycol 4000 mixed with dry powder in a ratio of 2.5:1, and the raw and auxiliary materials prepared in each group are heated to the molten state by electric heating, and the special dripping machine is used to adjust the temperature of the dripper. Keep it at 85±2℃; adjust the refrigeration control system of the dropping pill machine to keep the temperature of the condensate at 20→-5℃, and then prepare separately according to the process given in the previous [Detailed embodiments], you can get 3 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com