Solid phase extraction process for extracting and separating palladium

A solid-phase extraction agent and solid-phase extraction column technology, applied in the field of precious metal metallurgy, can solve problems such as being unsuitable for production and application, and achieve the effects of low cost, wide application range and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

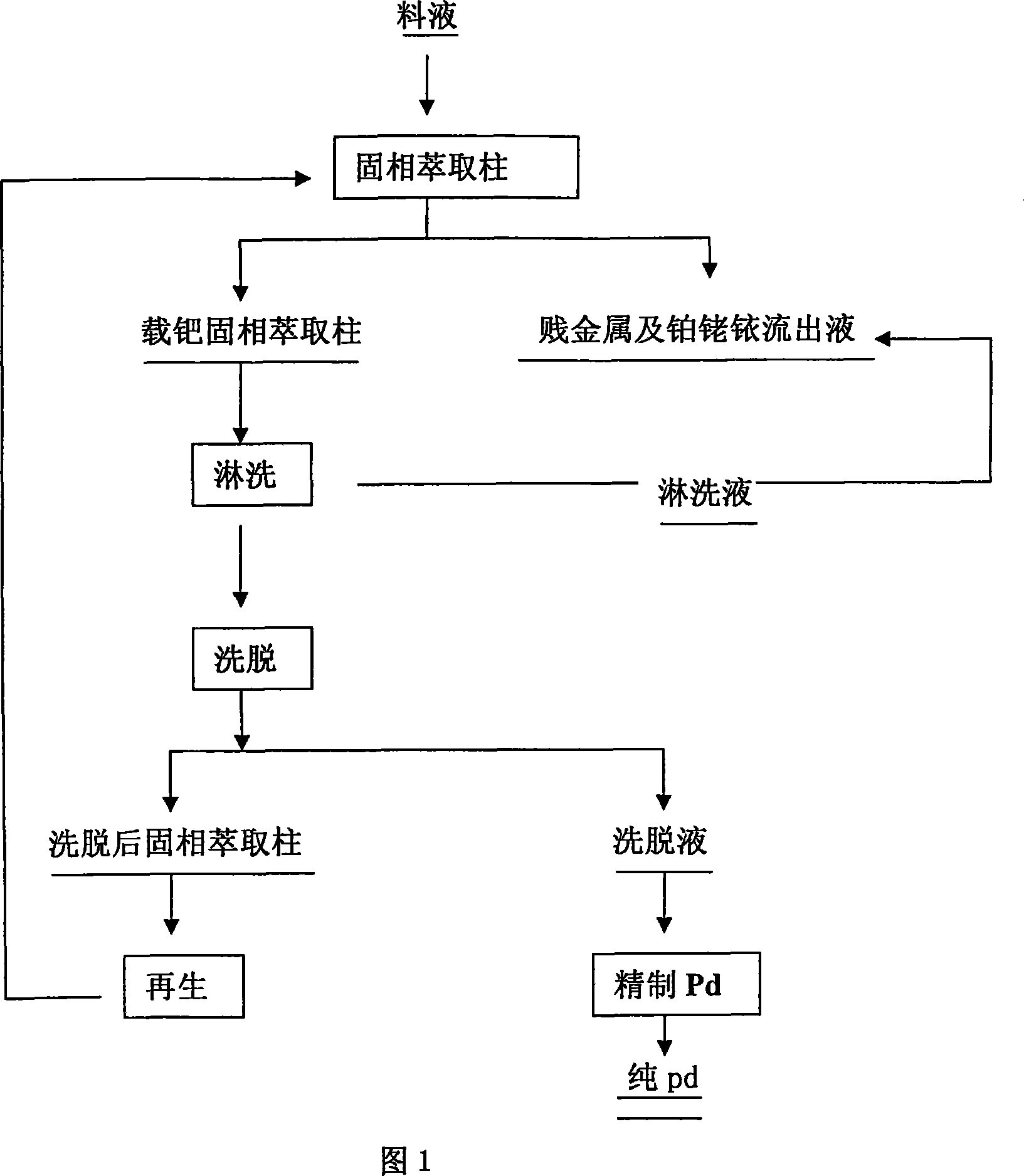

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Chloropalladic acid (H 2 PdCl 4 ) Solution, made by dissolving metal palladium in aqua regia to remove nitrate and making H 2 PdCl 4 Solution, containing 7.724g / L of palladium, and the concentration of medium hydrochloric acid is 0.1mol·L -1 , Use the methylene bisacrylamide and vinyl imidazole polymer bonded with cetyl sulfide extractant as the stationary phase, the particle size is 250μm, this stationary phase is filled in a φ15mm×400mm glass column, the material liquid The volume is 60mL, the column flow rate is 4.0mL / min, the eluent is 0.1mol / L hydrochloric acid 30mL, the flow rate is 3.0mL / min, the eluent is 2% thiourea solution 100mL, the flow rate is 5mL / min, and the injection volume It is 100mL. The effect of extracting Pd is shown in Table 1:

[0017] Table 1 From chloropalladium acid (H 2 PdCl 4 ) The effect of extracting Pd in solution

[0018] Element

Embodiment 2

[0019] Example 2: Weigh 5.00 g of 2,6-diacrylamide pyridine and diacrylamide-2-methyl-1-propanesulfonic acid polymer bound to the tetradecyl sulfoxide extractant as a stationary phase, and polymerize The particle size is 180μm, and it is added to 100mL hydrochloric acid solution containing 7.724g / L of palladium, shaken on a Conger shaker for 2h, filtered, and the content of metal Pd ions in the filtrate is determined. Calculate the static adsorption capacity of the polymer composite microsphere polymer for palladium.

[0020] Table 2 Determination of static adsorption capacity

[0021] Element

Embodiment 3

[0022] Example 3: The composition of the material liquid obtained from the platinum group metal concentrate is simulated to contain 3.752g / L of palladium, 5.019g / L of platinum, 0.562g / L of rhodium, 0.125g / L of iridium, 1.254g / L of copper, and iron. The test was carried out on synthetic samples of 1.221g / mL, zinc 1.192g / mL and nickel 0.832g / mL. Use pentaerythritol trimethacrylate bonded with n-hexadecyl sulfide and 4-styryl-nitrosodiacetic acid polymer as the stationary phase, the particle size is 550μm, and the size of the solid phase extraction column is φ15mm×400mm; The injection volume is 32.00 mL, the medium hydrochloric acid concentration is 0.1 mol / L, the feed liquid flow rate is 3 ml / min, the eluent is 0.1 mol / L hydrochloric acid 20 mL, the flow rate is 3.0 mL / min, and the eluent is 2% thiourea solution 50mL, the flow rate is 3mL / min, the solid phase extraction column is regenerated with 40mL of 0.1mol / L hydrochloric acid.

[0023] Table 3 Separation test results of palladi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com