Platinum icosahedron nano crystal catalyst, its preparing method and use

A technology of icosahedron and nanocrystals, applied in the field of nanocatalysts and their preparation, can solve problems such as inability to prepare nanocrystals, and achieve the effects of controllable particle size and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

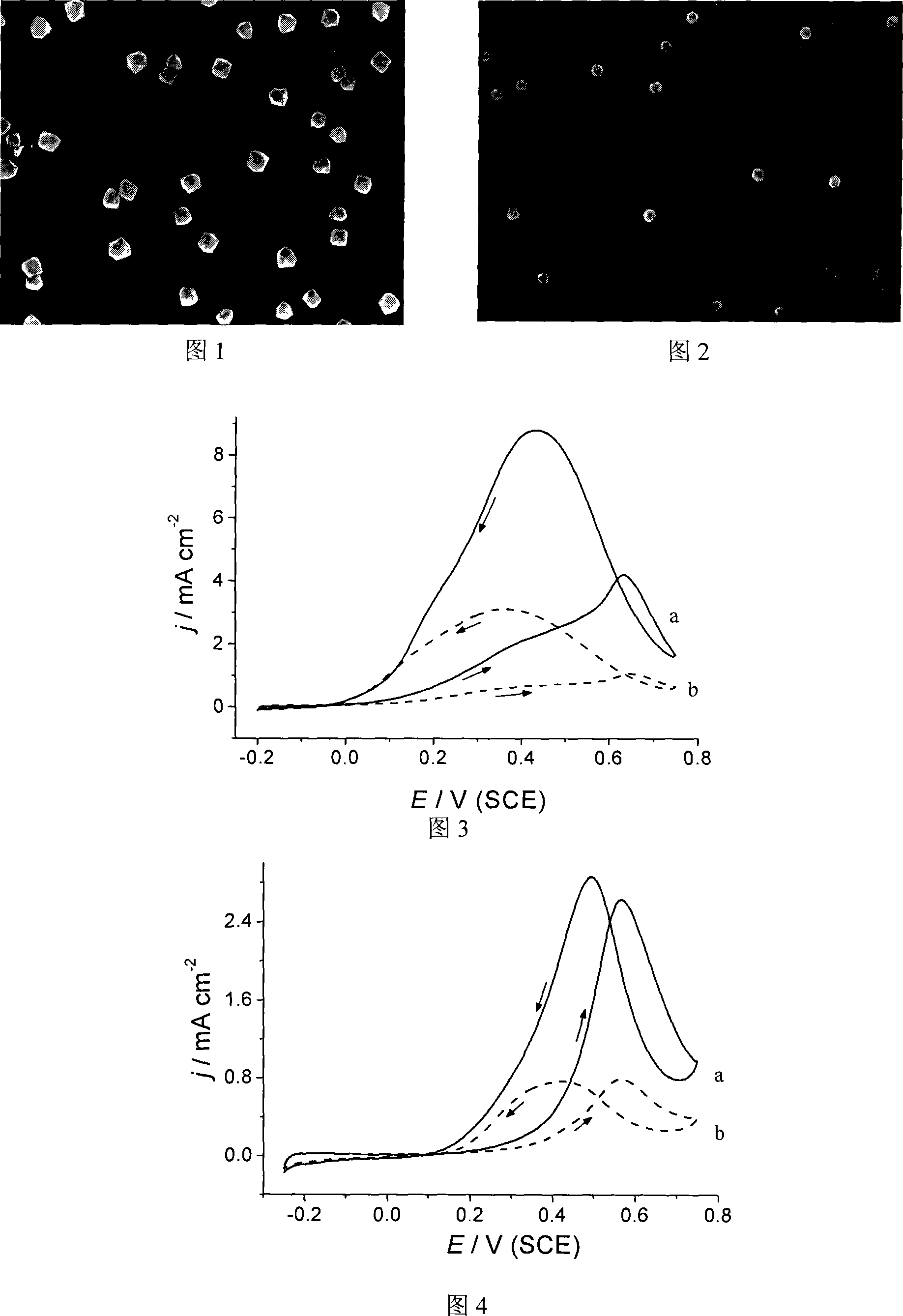

[0024] Embodiment 1: Preparation of platinum nanoparticles: glassy carbon (6mm in diameter) substrate is used as a working electrode, and a saturated calomel electrode is used as a reference electrode, and the working electrode and the reference electrode are put into In the platinum plating solution of sulfuric acid, a square wave potential is applied between the working electrode and the reference electrode for electrodeposition. The upper limit potential of the square wave is 0.50V, the lower limit potential is 0.10V, the square wave frequency is 10Hz, and the time is 40min. 1000nm platinum nanoparticles were obtained. Preparation of platinum tetrahedral nanocrystal catalyst: the glassy carbon substrate loaded with platinum nanoparticles is used as the working electrode, and the saturated calomel electrode is used as the reference electrode, and the working electrode and the reference electrode are placed in 0.1M sulfuric acid containing 100mM ascorbic acid In the solution,...

Embodiment 2

[0025] Embodiment 2: Similar to the process of Example 1, but when preparing platinum nanoparticles, the upper limit potential of the square wave is 0.80V, the lower limit potential is 0.30V, the frequency of the square wave is 50Hz, and the time is 20min, making about 400nm platinum nanoparticles. When preparing the platinum tetrahedral nanocrystal catalyst, the solution is 0.1M sulfuric acid without additives. The upper limit potential of the square wave is 1.0V, the lower limit potential is -0.20V, the frequency of the square wave is 50Hz, and the treatment time is 10min, and a platinum tetrahedral nanocrystal catalyst with a particle size of about 20nm is prepared. Fig. 2 is a SEM image of the platinum nanocrystal catalyst, and it can be seen from Fig. 2 that the platinum nanocrystal catalyst still maintains the shape of a tetrahedron.

Embodiment 3

[0026] Embodiment 3: Similar to the process of Example 1, but when preparing platinum nanoparticles, the upper limit potential of the square wave is 0.70V, the lower limit potential is 0.20V, the square wave frequency is 50Hz, and the time is 40min, and the platinum of 700nm is obtained Nanoparticles. When preparing the platinum tetrahedral nanocrystal catalyst, the solution was 0.1 M sulfuric acid containing 30 mM ascorbic acid. The upper limit potential of the square wave is 1.10V, the lower limit potential is -0.30V, the frequency of the square wave is 20Hz, and the treatment time is 30min, and the platinum tetrahedron nanocrystal catalyst is prepared. Fig. 3 is the catalytic activity characterization figure of platinum tetrahedral nanocrystal catalyst (Pt THH) to formic acid, shows that its catalytic activity per unit surface area is obviously better than the commercialization platinum nanocrystal catalyst E-TekPt / C (20 wt%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com