Decorative material made from rape straw and preparing method

A decorative material, rape straw technology, applied in the field of comprehensive utilization of crop by-products, to achieve the effect of saving consumption and protecting the natural environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

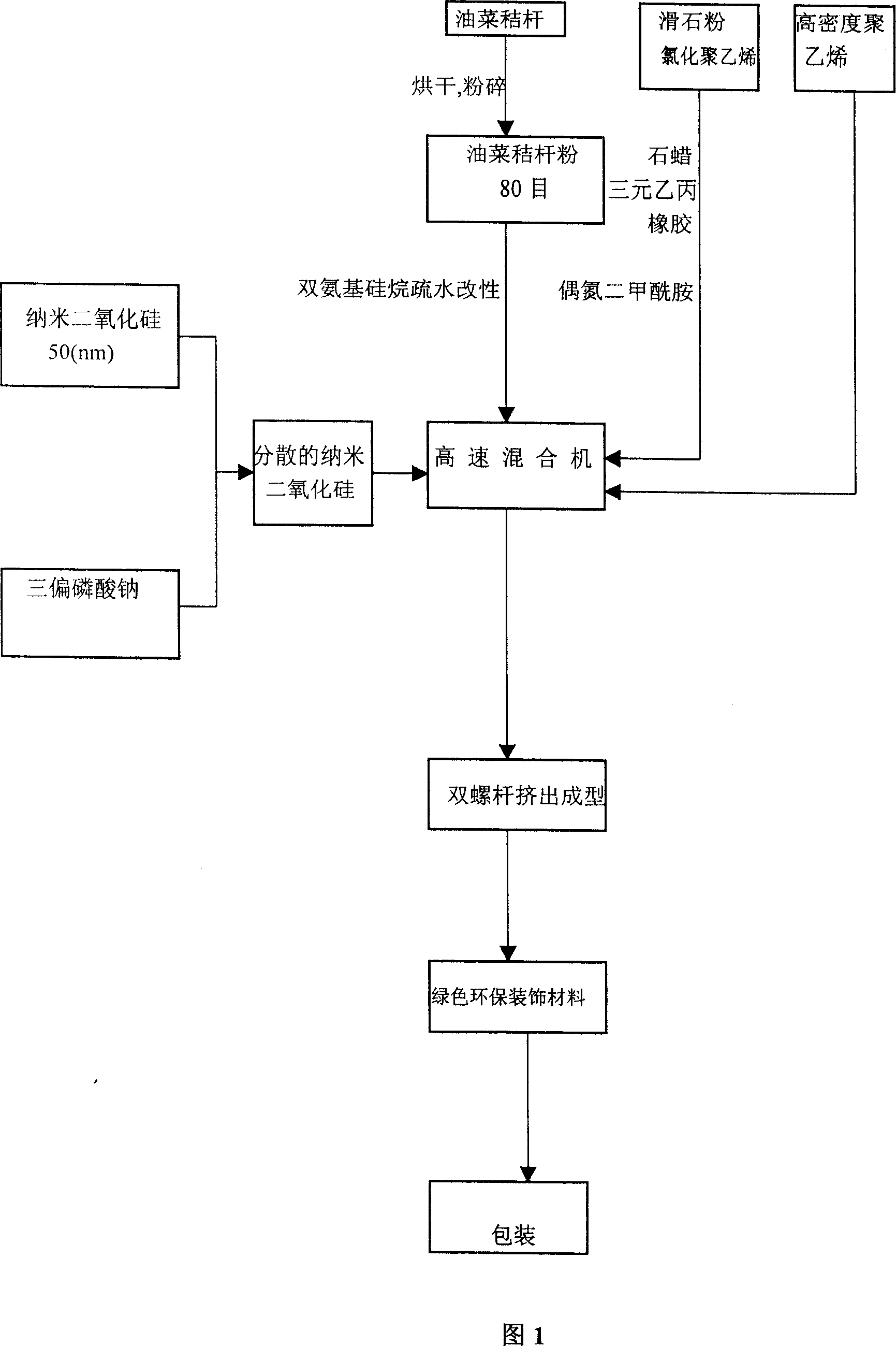

Method used

Image

Examples

Embodiment 1

[0036] Weigh 50nm nano-silica (purchased from China National Nano Engineering Center commodity) 1.5kg and sodium trimetaphosphate 0.8kg, mix it in a glass container; Put into the ball mill cylinder body of 45r / min after mixing, make described nano silicon dioxide fully disperse; Weigh and dry to water content and be 3% through the pulverized rape straw powder 100kg of 80 mesh analytical sieves, and add 1.3kg of aminosilane was placed in a high-speed mixer, mixed for 10 minutes at 90°C, and then 20kg of high-density polyethylene, 6 kg of talcum powder, 2 kg of chlorinated polyethylene, and EPDM were added to the high-speed mixer in turn. 2 kilograms of rubber, 1 kilogram of paraffin and 1 kilogram of foaming agent azodicarbonamide are placed in a high-speed mixer, mixed for 15 minutes at 110 ° C, and the obtained mixed material is extruded in a twin-screw extruder. The heating temperature T1-T6 of each section is 90°C, 124°C, 154°C, 150°C, 132°C and 125°C respectively, the spee...

Embodiment 2

[0038]Weigh 50nm nano silicon dioxide (commodity purchased from China National Nano Engineering Center) 1.5kg and sodium trimetaphosphate 0.8kg, mix it in a glass container, and mix described nano silicon dioxide and sodium trimetaphosphate Put into the ball mill cylinder body of 45r / min after mixing, make described nano silicon dioxide fully disperse; Weigh and dry to water content and be 3% through the pulverized rape straw powder 100kg of 80 mesh analytical sieves, and add 1.3kg of aminosilane is placed in a high-speed mixer, mixed for 10 minutes at 90°C, and then 30kg of high-density polyethylene, 6 kg of talcum powder, 2 kg of chlorinated polyethylene, and EPDM are added to the high-speed mixer in turn. 2 kg of rubber, 1 kg of paraffin and 1 kg of blowing agent azodicarbonamide are placed in a high-speed mixer, mixed for 15 minutes at 110 ° C, and the obtained mixed material is extruded in a twin-screw extruder. The heating temperatures T1-T6 are 90°C, 124°C, 154°C, 150°C...

Embodiment 3

[0040] Weigh 50nm nano-silica (purchased from China National Nano Engineering Center commodity) 1.5kg and sodium trimetaphosphate 0.8kg, mix it in a glass container; Put into the ball mill cylinder body of 45r / min after mixing, make described nano silicon dioxide fully disperse; Weigh and dry to water content and be 3% through the pulverized rape straw powder 100kg of 80 mesh analytical sieves, and add 1.3kg of aminosilane is placed in a high-speed mixer, mixed for 10 minutes at 90°C, and then added to the high-speed mixer in turn 25kg of high-density polyethylene, 6 kg of talcum powder, 2 kg of chlorinated polyethylene, EPDM 2 kilograms of rubber, 1 kilogram of paraffin and 1 kilogram of blowing agent azodicarbonamide were placed in a high-speed mixer, and mixed for 15 minutes at 110 ° C, and the obtained mixed material was extruded in a twin-screw extruder, each The section heating temperatures T1-T6 are 90°C, 124°C, 154°C, 150°C, 132°C and 125°C respectively, the speed of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com