Method for cryogenic cooling absorbing-regenerative oxidation recovery and treating oil air

A technology of cooling absorption and heat storage, which is applied in solvent recovery, gas purification, and petrochemical fields. It can solve problems such as uneconomical and non-standard gas discharge, and achieve the effects of small footprint, outstanding comprehensive economy, and large operating flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

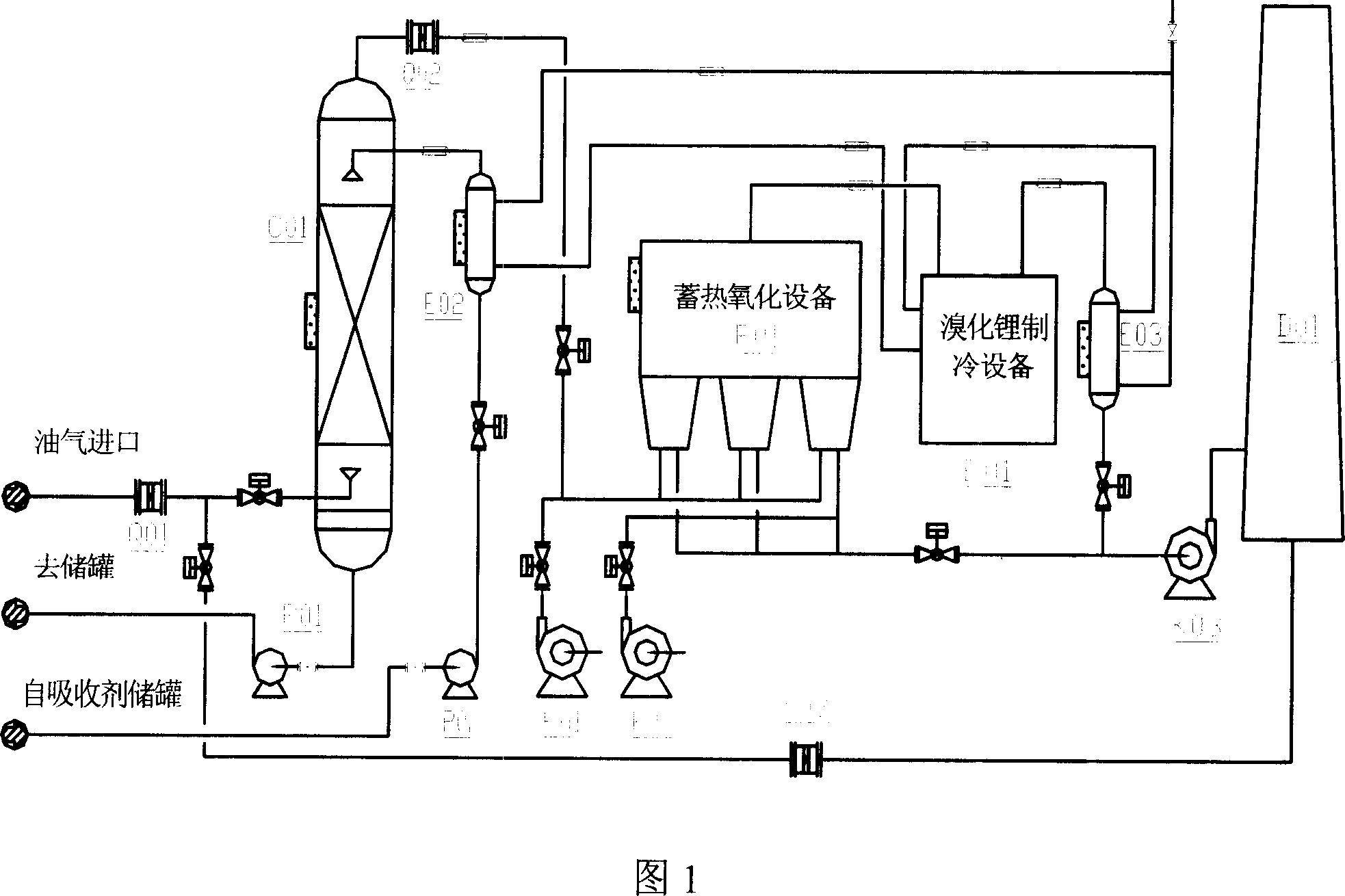

[0019] Take benzene-containing oil and gas as an example: oil and gas are collected through a closed loading system, pass through a flame arrester (Q01), and enter the absorption tower (C01) from the bottom of the absorption tower. The temperature is normal temperature, the pressure is 3000-5000Pa, and the benzene concentration is about 180g / Nm 3 (20°C). In the absorption tower (C01), it is fully countercurrently contacted with the absorption liquid kerosene at about 10°C, and then discharged from the top of the tower. The absorption rate of benzene in oil and gas is greater than 90%, and the concentration of benzene in the tower is about 18g / Nm 3 , temperature 10 ~ 15 ℃, pressure loss of about 1000Pa. The oil and gas coming out of the tower enter the thermal storage and oxidation section through the flame arrester (Q02), and after being diluted with fresh air 5 times the air volume, the oil and gas concentration is about 4g / Nm 3 , the temperature is close to normal temperat...

Embodiment 2

[0023] Take gasoline oil and gas as an example: the concentration of gasoline is about 700g / Nm 3 (20°C). After full countercurrent contact with the absorption liquid kerosene at about 10°C in the absorption tower, it is discharged from the top of the tower. The absorption rate of gasoline in oil and gas is greater than 80%, and the concentration of gasoline out of the tower is about 140g / Nm 3 . The oil and gas coming out of the tower enter the thermal storage oxidation section through the flame arrester (Q02), and after being diluted with fresh air 10 times the air volume, the oil and gas concentration is about 14g / Nm 3 , the temperature is close to normal temperature, it is preheated through the heat storage bed in the heat storage oxidizer (R01), and the oil gas is completely oxidized in the oxidation chamber, and the concentration is less than 100mg / Nm 3 , the temperature is 700°C, after the gas stays in the oxidation chamber for about 1.0 seconds, it passes through anot...

Embodiment 3

[0025] Take butanone oil and gas as an example: the concentration of gasoline is about 130g / Nm 3 (20°C). After full countercurrent contact with the absorption liquid kerosene at about 10°C in the absorption tower, it is discharged from the top of the tower. The absorption rate of gasoline in oil and gas is greater than 90%, and the concentration of gasoline out of the tower is about 13g / Nm 3 . The oil and gas coming out of the tower enter the thermal storage oxidation section through the flame arrester (Q02), and after being diluted with fresh air twice the air volume, the oil and gas concentration is about 6.5g / Nm 3 , the temperature is close to normal temperature, it is preheated through the heat storage bed in the heat storage oxidizer (R01), and the oil gas is completely oxidized in the oxidation chamber, and the concentration is less than 100mg / Nm 3 , the temperature is 700°C, after the gas stays in the oxidation chamber for about 2.5 seconds, it passes through another...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com