Organic electroluminescent device with hybrid illuminating layer

A technology of electroluminescent devices and light-emitting layers, which is applied in the direction of electroluminescent light sources, electric solid-state devices, electrical components, etc., can solve the problems of low luminous efficiency of devices, and achieve the effect of improving luminous efficiency and enhancing brightness efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

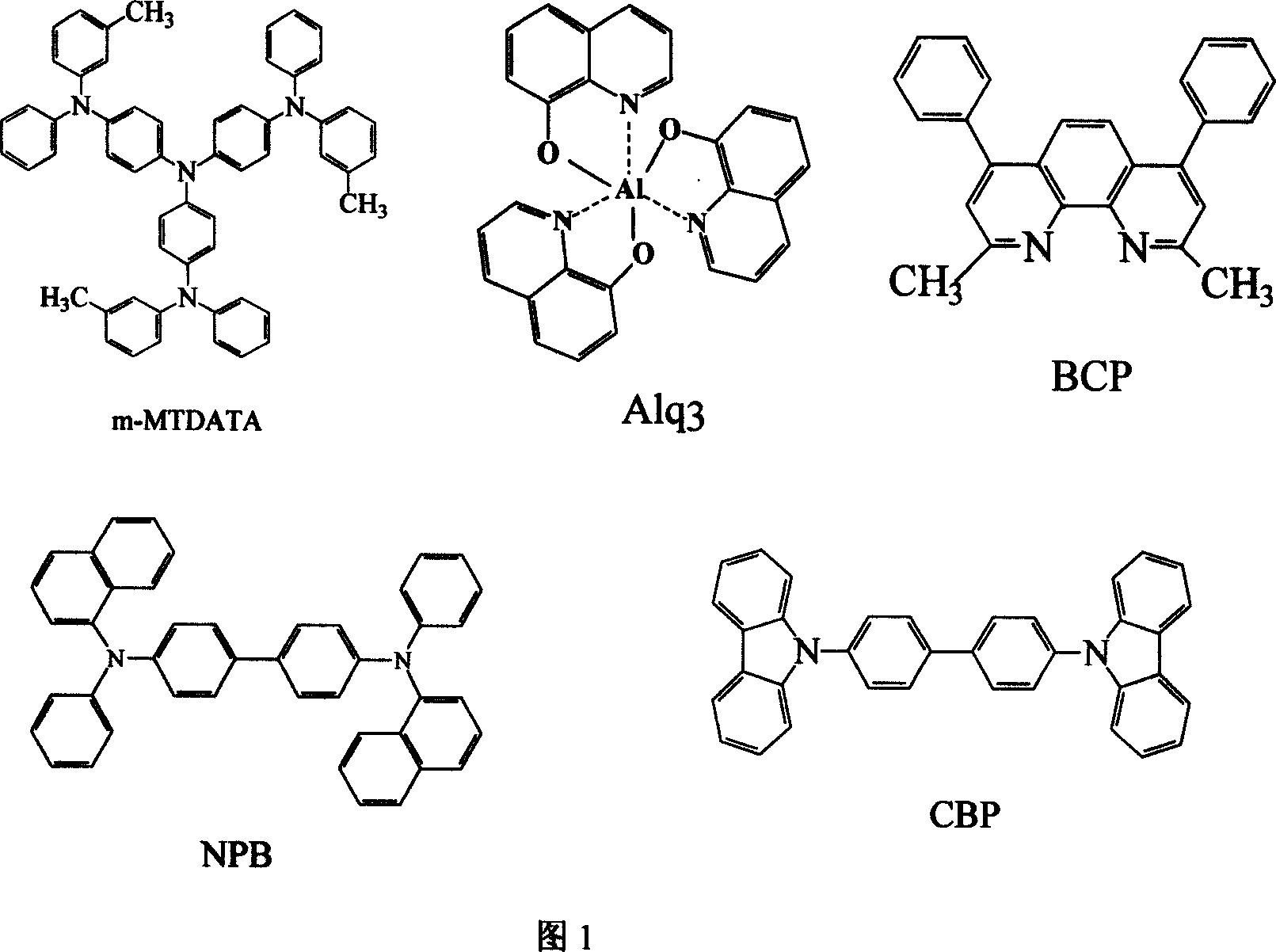

[0049] Figure 1 shows the structure of the organic small molecule material in this study. OLEDs are fabricated on ITO. The thickness of the ITO layer is about 60nm, and its sheet resistance is 50Ω. Conventional cleaning steps include ultrasonic cleaning the ITO layer in acetone, alcohol, isopropanol, and deionized water, and finally irradiating it in an oxygen plasma chamber. After treatment in an oxygen plasma chamber, the ITO substrate was placed in a vacuum chamber for device fabrication. This main vacuum chamber houses ten emission sources, each heated by a tantalum heater, the opening and closing of the baffles controls the deposition sequence, deposition rate and thickness by a quartz oscillator consisting of a crystal sensor and frequency counter device measurement. In order to obtain a large-area uniform film and a steep interface, three types of baffles are installed in the vacuum chamber. For example, in addition to the baffles used for the crucible, there is also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com