Water treatment new combined technique with high purification function

A water treatment and new combination technology, applied in water/sewage treatment, biological water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problem of reduced water production, rapid decline in membrane flux, unstable effluent quality up to standard and other problems, to achieve the effect of purification function, energy saving and consumption reduction, slow decline of carrier flux, and easy elimination of carrier pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach : Embodiment 1

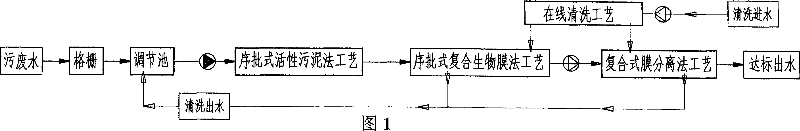

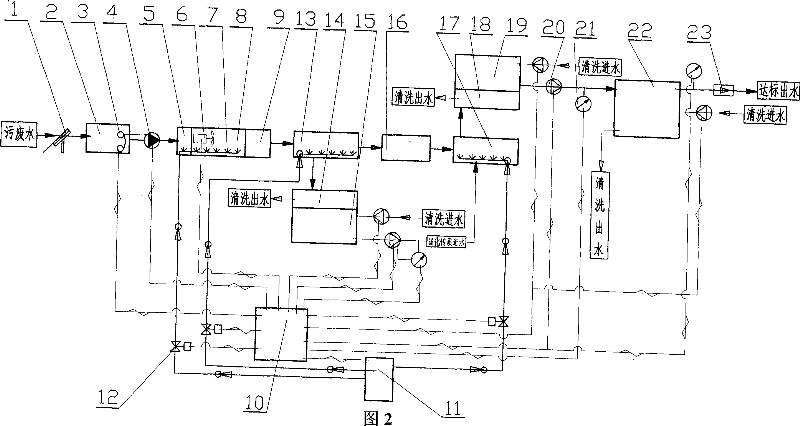

[0032] Specific implementation methods: Example 1. The sewage of the present invention is sequentially combined and treated by the sequential batch activated sludge process, the sequential batch composite biofilm process, and the composite membrane separation process to reach the standard; at the same time, the online cleaning process Clean the ultra-microfiltration membrane elements and other filtration membrane elements of the sequencing batch composite biofilm process and the composite membrane separation process;

[0033] In the process link of the sequencing batch activated sludge process, a precipitation zone 9 is set after the pre-reaction zone 5 and the main reaction zone 8;

[0034] In the process link of the sequence batch type composite biofilm method, after the sedimentation zone 9 of the sequence batch type activated sludge tank, a first-level biofilm reaction tank 13, a water collection tank 14 and a multimedia filter device 15 are respectively arranged in sequenc...

Embodiment 2

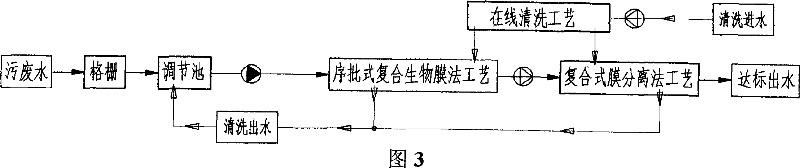

[0037] Embodiment 2, the waste water of the present invention is treated sequentially by the sequential batch composite biofilm process and the composite membrane separation process and then reaches the standard; at the same time, the sequence batch composite biofilm process and the composite membrane are treated by the online cleaning process. The ultra-microfiltration membrane element and other filter membrane elements of the separation process are cleaned;

[0038] In the process link of the sequence batch compound biofilm method, a first-level biofilm reaction tank 13, a water collection tank 14 and a multimedia filter device 15 are arranged in sequence, and a second-level biofilm reaction tank 17 is arranged after the secondary sedimentation tank 16;

[0039] In the sequence batch composite biofilm process, the structure of the composite biofilm reaction tank is divided into a fluid bed or a fixed bed, and the carrier structure of the composite biofilm is composed of upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com