Array giant magnetic impedance effects current sensor

A current sensor and giant magneto-impedance technology, applied in the field of current measurement devices, can solve the problems of expanding the measurement range, low noise, etc., and achieve the effects of simple electronic circuit, improved signal-to-noise ratio, and improved linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

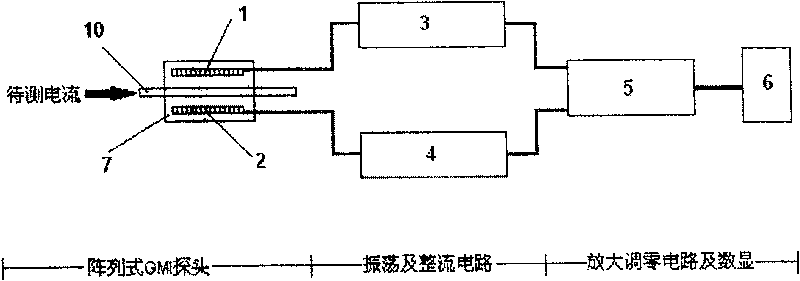

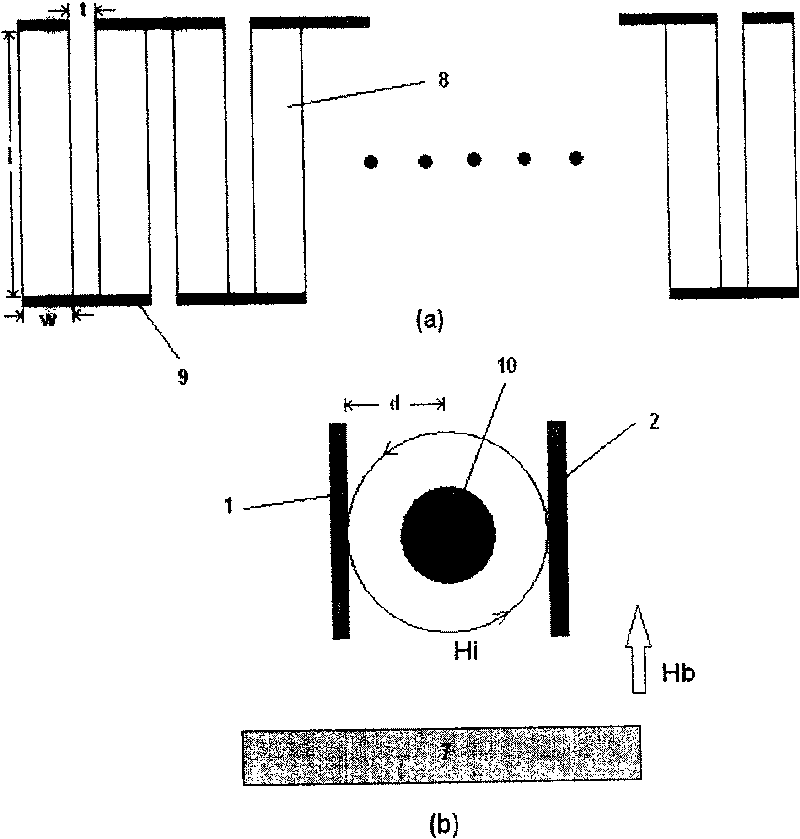

[0035] figure 2 Among them, 1 and 2 are arrayed amorphous current sensor probes, and 7 is a permanent magnet (such as ferrite, NdFeB, etc.), and block (cuboid) ferrite is used in the specific example. 8 is an amorphous strip unit, 9 is a copper wire, and 10 is a copper wire passing a current to be measured.

[0036] Array type amorphous current sensor probe 1 and array type amorphous current sensor probe 2 are respectively welded by 16 rectangular amorphous strip units 8 with good soft magnetic properties and copper wires 9 in series, and the length of amorphous strip unit 8 is 10mm , 2.5mm wide, 30um thick, the distance between the two amorphous strip units is 1mm, and the array type amorphous current sensor probe 1 and the array type amorphous current sensor probe 2 have the same requirements, symmetrically placed on both sides of the current conducting wire 10, When the current passes through the wire 10, a circular magnetic field H is generated around the wire i . The o...

Embodiment 2

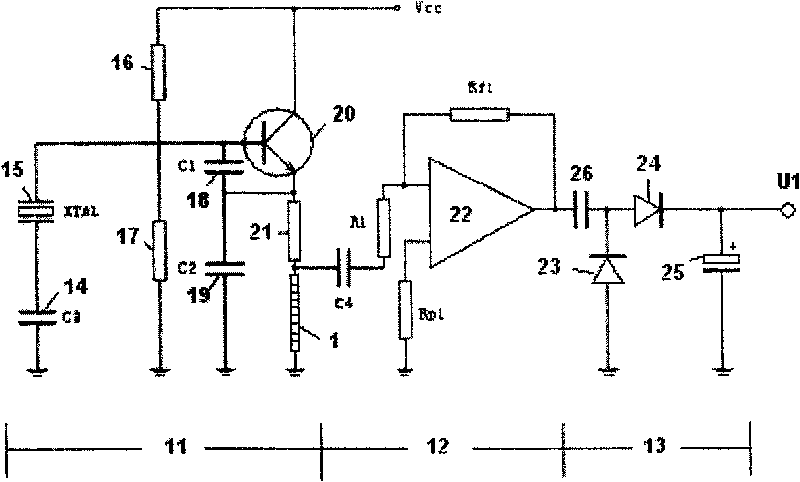

[0041] image 3 Among them, 1 is an array type amorphous current sensor probe, 11 is a Colpitts oscillator circuit, 12 is a preamplifier circuit, and 13 is a rectifier circuit. 14 is the starting capacitor C 3 , 15 is the crystal oscillator, 16 and 17 are two voltage divider resistors with equal resistance, and 18 is the feedback capacitor C 1 , 19 is the feedback capacitor C 2 , 20 is a transistor, 21 is an emitter current limiting resistor, 22 is a high-frequency operational amplifier, 23, 34 are two rectifier diodes, 25 is a voltage stabilizing capacitor, and 26 is a filter capacitor.

[0042] The power supply voltage Vcc of the Corbitz oscillation circuit 11 can be 12V, and the static operating point of the base of the transistor 20 is designed to be stable. Since the resistance values of the two divider resistors 16 and 17 are equal, the static operating voltage of the base of the transistor 20 is 6V. , the transistor 20 emitter static operating voltage is stable at ...

Embodiment 3

[0051] An embodiment of the data of each part of the circuit element is given.

[0052] image 3 Among them, the transistor 20 uses a high-frequency transistor of the type 2SC1815, and its cut-off frequency f T 5 times higher than crystal oscillator 15 frequency. The frequency of the crystal oscillator 15 is above 1 MHz, and the starting capacitor 14 is 15 pF˜10 nF, which can start the oscillation. The two voltage dividing resistors 16 and 17 can be selected as 10kΩ; the injector current limiting resistor 21 is 390Ω; the feedback capacitor 18 is 1000pF-2200pF, the feedback capacitor 19 is 60pF-200pF, and the ratio of the feedback capacitor 18 to the feedback capacitor 19 is 2 to 25 between. The oscillating frequency of the Corbitz oscillating circuit is the frequency of the crystal oscillator 15 .

[0053] image 3 In the preamplifier circuit 12, the gain-bandwidth product GBP should be selected as a high-frequency operational amplifier with a gain-bandwidth product GBP t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com