Nanometer silver antibiotic powder fixed by silk fibroin and preparation method thereof

A technology of nano-silver and antibacterial powder, which is applied in the fields of botanical equipment and methods, animal repellents, biocides, etc., can solve the problem of difficult to realize the preparation of silk fibroin-immobilized nano-silver antibacterial powder, the concentration of nano-silver fibroin sol Low cost, without considering the problems of nano-silver antibacterial powder, etc., to achieve the effects of good biocompatibility, simple manufacturing process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

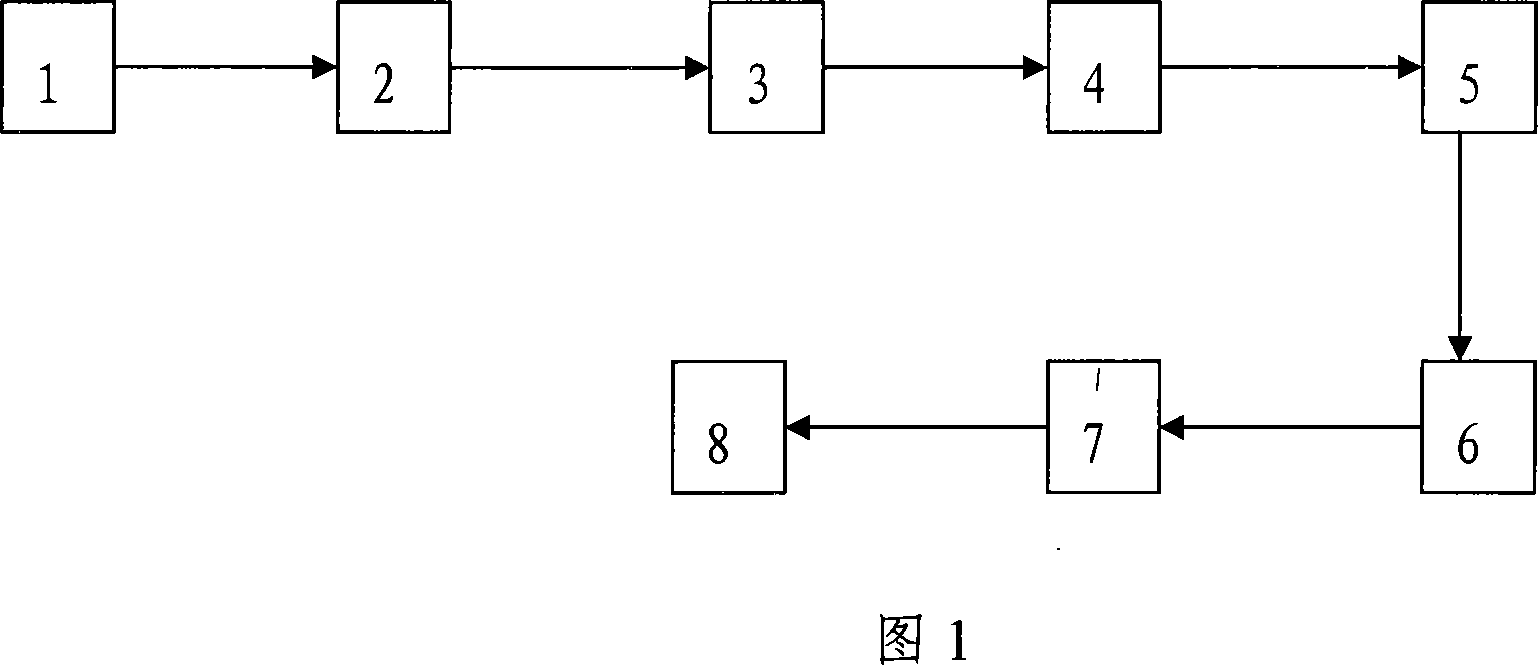

Method used

Image

Examples

Embodiment 1

[0023] 1. Select clean and decontaminated silk in 0.5% Na 2 CO 3 In aqueous solution, degumming twice at 100°C, 1 hour each time, bath ratio 1:50. The degummed silk fibroin was dried in a drying oven at 80°C until dry.

[0024] 2. Place the dried silk fibroin in CaCl 2 : C 2 h 5 OH:H 2 In the mixed solution of O=1:2:8 (molar ratio), bath ratio 1:10, dissolve at 80±5°C for 30 minutes, filter the solution under reduced pressure, put it in a cellulose semi-permeable membrane, and dialyze it with distilled water for desalination. Make silk fibroin solution, its concentration is 0.5~15%, preferably concentrate or dilute to about 10% silk fibroin solution.

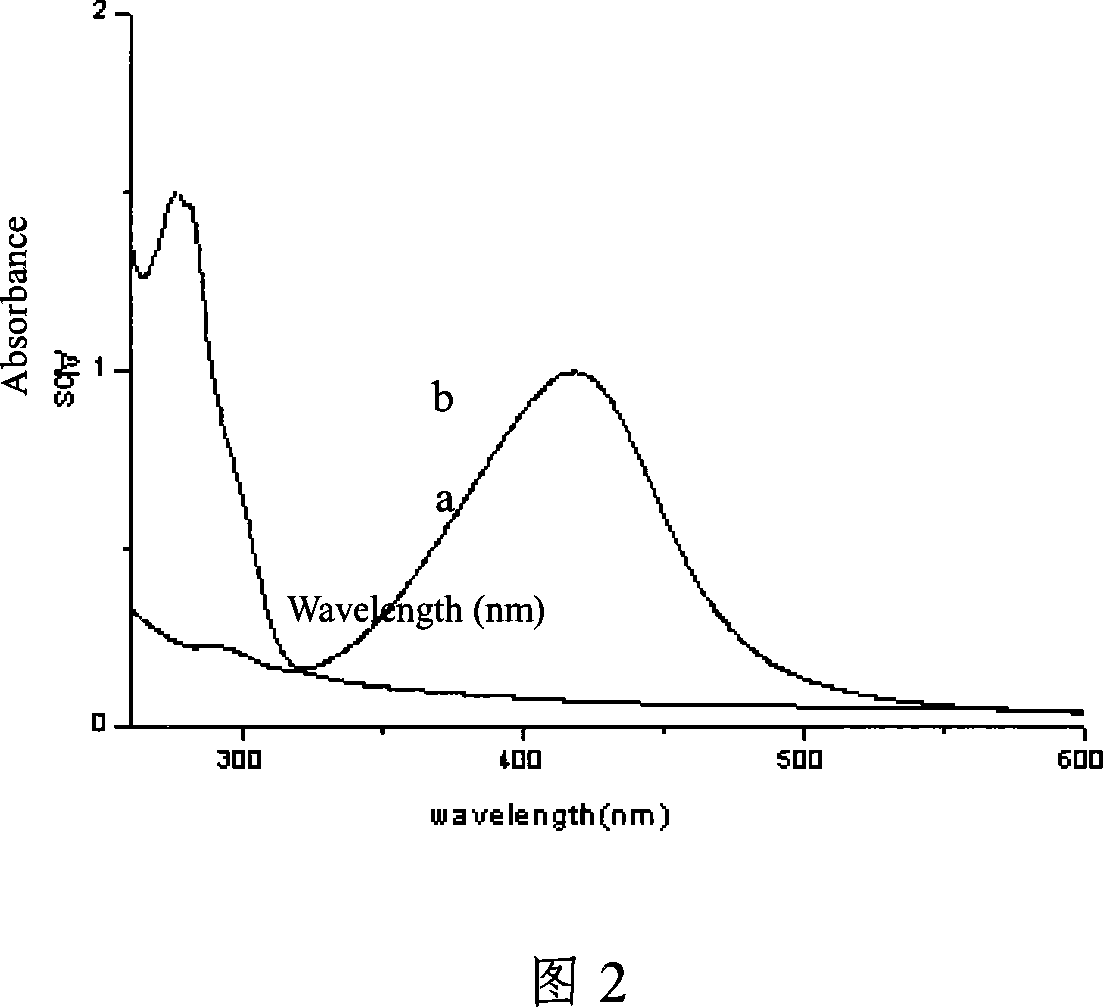

[0025] 3. Take 10g of the above silk fibroin solution and add it dropwise to 10g of 0.1% AgNO 3 In the aqueous solution, use 20% NaOH solution to adjust the pH value of the mixed solution to 9-10, place it at 25°C, the color of the solution gradually changes from colorless to yellow, and react for 10 hours to prepare the ...

Embodiment 2

[0031] 1. Silk degumming is the same as in Example 1.

[0032] 2. Place the dried silk fibroin in 40% CaCl 2In the solution, the bath ratio is 1:20, dissolved at 100°C for 5 minutes, filtered the solution under reduced pressure, installed in a cellulose semipermeable membrane, dialyzed and desalted with distilled water, and made silk fibroin solution with a concentration of 0.5% to 15%. It is best to concentrate or dilute to about 8% silk fibroin solution.

[0033] 3. Take 10g of the above silk fibroin solution and add it dropwise to 10g of 0.2% AgNO 3 In the aqueous solution, use 20% NaOH solution to adjust the pH value of the mixed solution to 8-9, place it at 10°C, the color of the solution gradually changes from colorless to yellow, and place it for 12 hours to obtain the nano-silver fibroin solution.

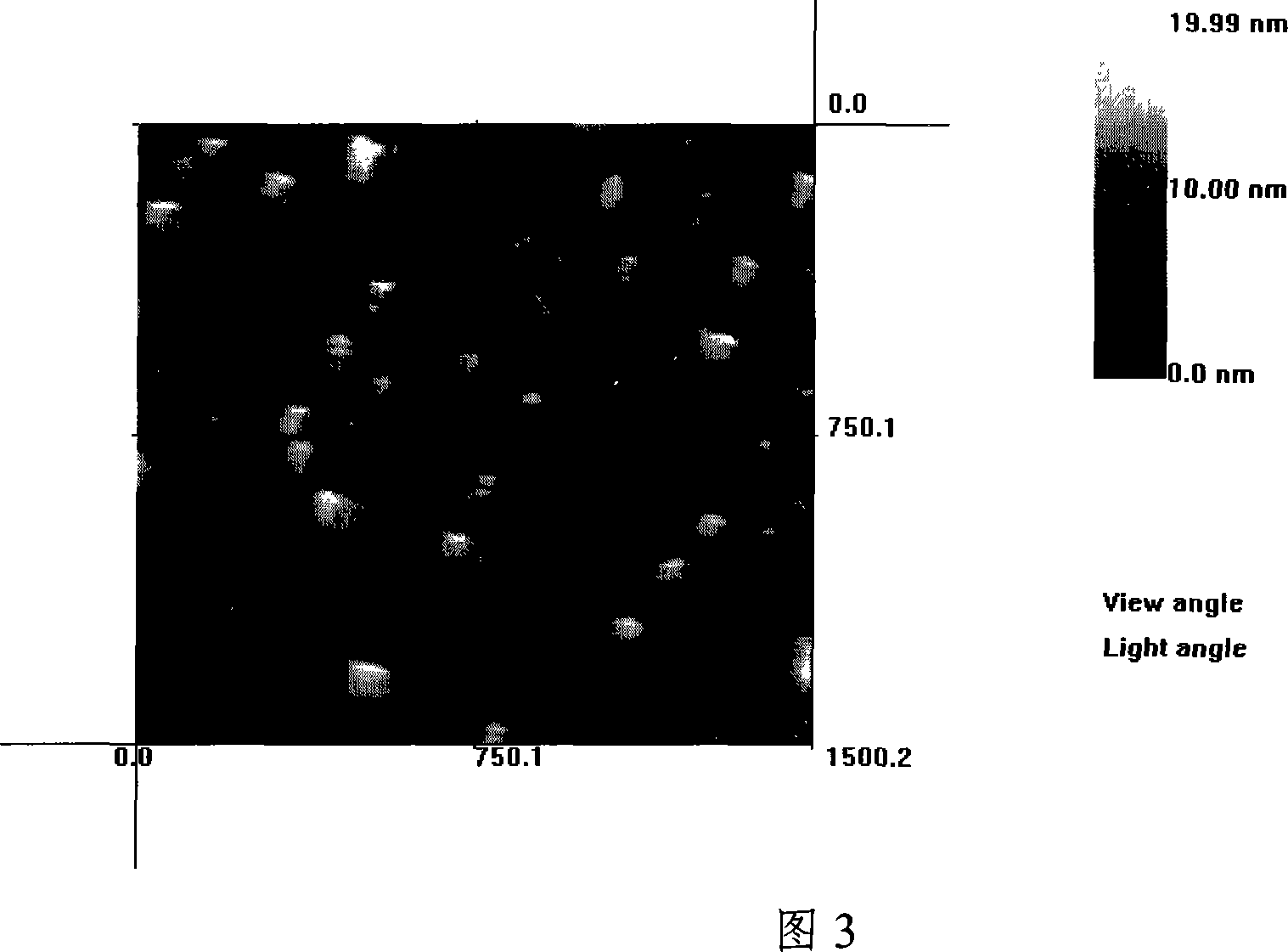

[0034] 4. Spray-dry the prepared nano-silver fibroin solution at an inlet temperature of 185-190°C and an outlet temperature of 80-85°C to obtain silk fibroin with an ave...

Embodiment 3

[0036] 1. Silk degumming is the same as in Example 1.

[0037] 2. Put the dried silk fibroin in 6mol / L hydrochloric acid solution, bath ratio 1:25, dissolve at 85°C for 1.5 hours, filter the solution under reduced pressure, put it in a cellulose semi-permeable membrane, and dialyze it with distilled water for desalination. Make silk fibroin solution, its concentration is 0.5~15%, preferably concentrate or dilute to about 8.5% silk fibroin solution.

[0038] 3. Take 10g of the above silk fibroin solution and add it dropwise to 10g of 0.15% AgNO 3 In the aqueous solution, use 10% HCl solution to adjust the pH value of the mixed solution to 4-5, place it at 5°C, the color of the solution gradually changes from colorless to yellow, and place it for 24 hours to obtain the nano-silver fibroin solution.

[0039] 4. Vacuum freeze-dry the prepared nano-silver fibroin solution at -50°C to obtain uniform particles with an average particle size of silk fibroin of about 175nm and an avera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com