PravastatinNa pills, and preparation method

A technology of pravastatin sodium and pravastatin sodium dripping pills, which is applied in the direction of pill delivery, metabolic diseases, active ingredients of esters, etc. It can solve the problems of low bioavailability, long disintegration time, and affecting drug efficacy, and achieve bioavailability High degree of drug stability, fast onset of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

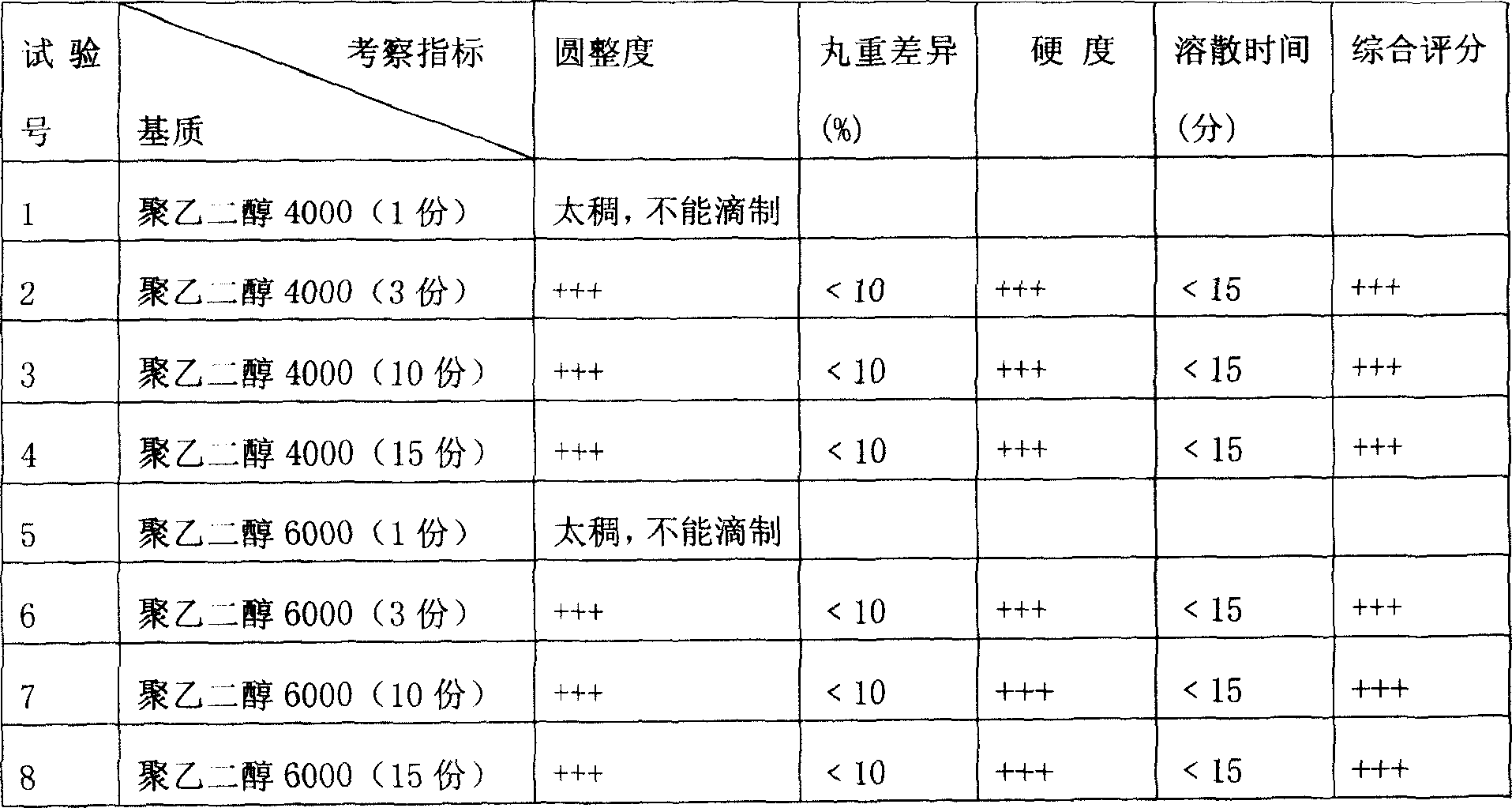

[0026] Example 1: In this example, through the formulation of pravastatin sodium and a single matrix, according to the preparation method in [Specific Implementation], the coolant is dimethyl silicone oil, dripping pills are made, and the roundness and the difference in pill weight are selected. , hardness, dissolving time etc. as indicators, observe the influence of the weight ratio of medicine and single matrix on the product involved in the present invention, the test results are shown in Table 1.

[0027] Table 1 Drug and single matrix formula test (all drugs are 1 part)

[0028]

[0029] Note: 1. The coolant is dimethyl silicone oil, the cooling temperature is 3~5℃; the temperature of the heat preservation of the medicinal material and the dripper is 85~90℃; the dripping speed is 30~50 grains / min.

[0030] 2. The above results show that the indexes of No. 2, 3, 4, 6, 7, and No. 8 tests are all good, that is, when the ratio of drug to matrix is 1:3 to 1:15, it ...

Embodiment 2

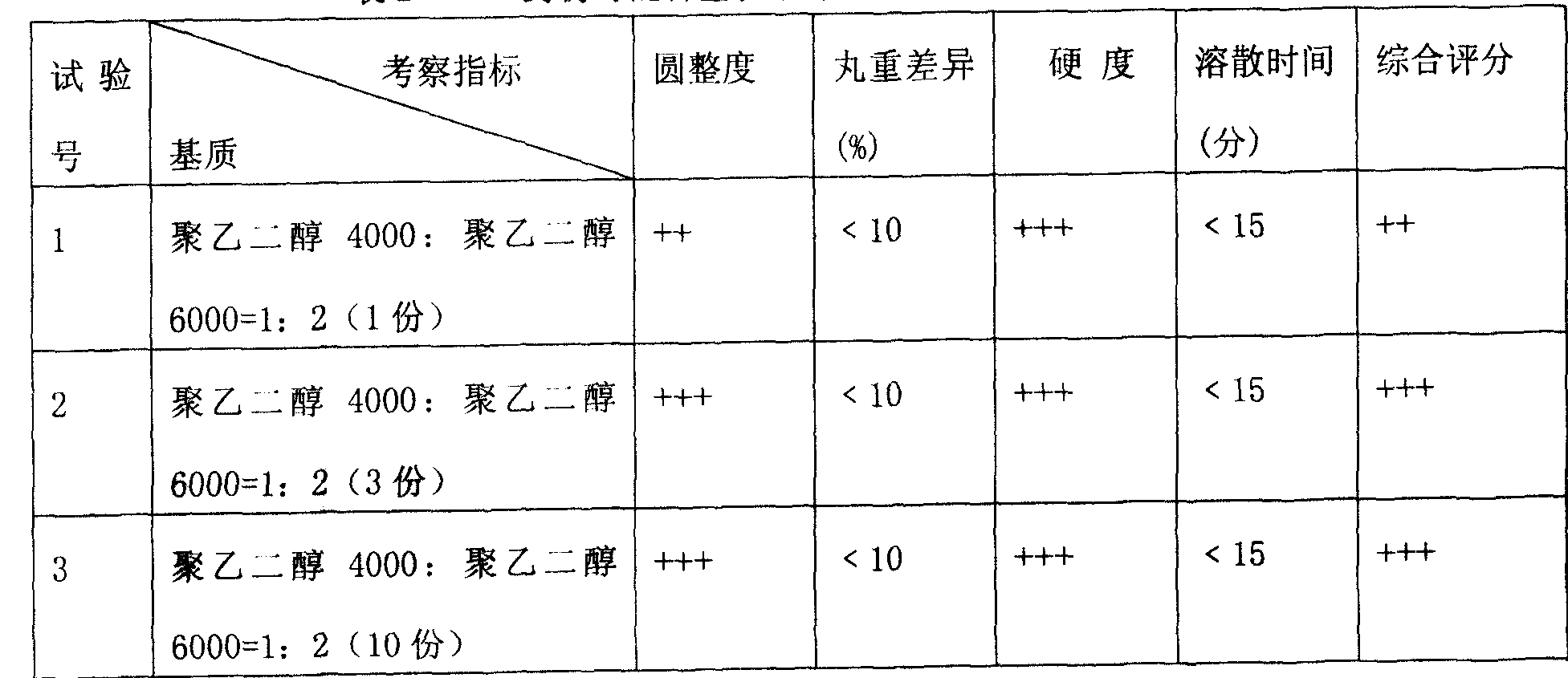

[0031] Example 2: In this example, the formulation of pravastatin sodium and mixed matrix is used, and the operation is performed according to the preparation method in [Specific Embodiments]. The coolant is dimethyl silicone oil, and the dropping pills are made by dropping, and the roundness and the difference in the weight of the pills are selected. , hardness, dissolving time etc. are the investigation indexes, observe the influence of the weight ratio of the medicine and the mixed matrix on the product involved in the present invention, and the test results are shown in Table 2.

[0032] Table 2 Drug and mixed matrix formula test (all drugs are 1 part)

[0033]

[0034] 4

Polyethylene Glycol 6000: Carboxymethyl Starch

Sodium = 1:0.3 (1 serving)

++

<10

+++

<15

++

5

Polyethylene glycol 6000: carboxymethyl starch

Sodium = 1:0.3 (3 parts)

+++

<10

+...

Embodiment 3

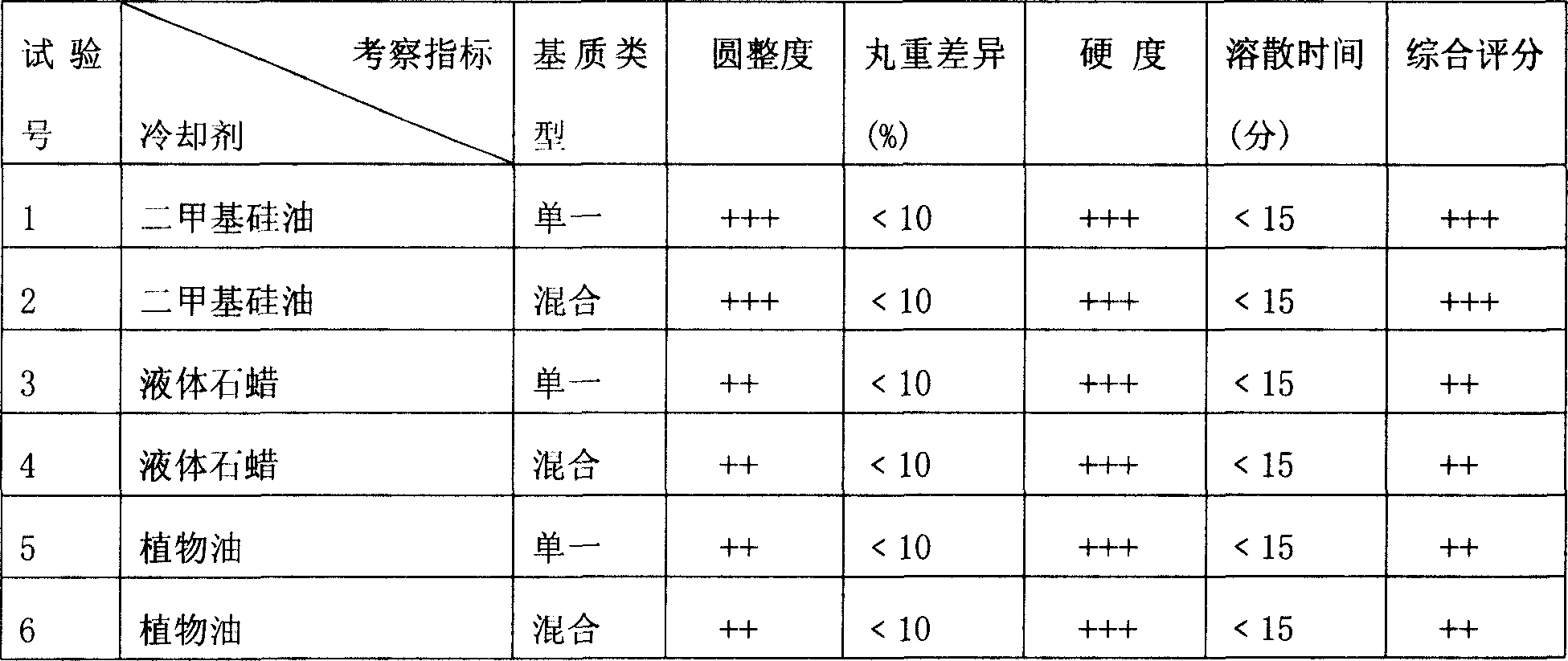

[0037] Embodiment 3: In this embodiment, different coolants are selected, and the coolants are dimethyl silicone oil, liquid paraffin, and vegetable oil, and polyethylene glycol is selected as a single substrate. 6000 , the mixed matrix is polyethylene glycol 6000 : The formula of poloxamer=1:0.2, operate according to the preparation method in [Specific Embodiments], drop the drop pills, select roundness, difference in pill weight, hardness, dissolution time and the like as investigation indicators, observe different The influence of the coolant on the products involved in the present invention, the test results are shown in Table 3.

[0038] Table 3 Experiments with different coolants (drug:substrate=1:3)

[0039]

[0040] Note: 1. The cooling temperature is 8~5℃; the temperature of the heat preservation of the medicinal material and the dripper is 85~90℃; the dripping rate is 30~50 capsules / min.

[0041] 2. The above results show that the indexes of No. 1 and N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com