Method of catalytically synthesizing liquid jet fuel from cyclopentadiene and bridge dicyclopentadiene

A technology of dicyclopentadiene and cyclopentadiene, which is applied in the field of jet fuel preparation, can solve the problems of serious environmental pollution of heterogeneous catalysts and high freezing point of liquid fuels, and achieve the effects of convenient and easy-to-obtain sources, low freezing point and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Add 300g of cyclopentadiene, 300g of bridged dicyclopentadiene and 150g of HZSM-5 molecular sieves with a particle size of 0.12 to 0.15mm into a reaction kettle with a volume of 1000mL. The stirring rate is 850rpm. Polymerization at 190°C for 20 hours to obtain the product;

[0013] The product was filtered under reduced pressure, and the filtrate was added to the still, and the unreacted raw materials were evaporated and recovered under the conditions of a pressure of 5kPa and a temperature of 130°C, and 451g of polymer was obtained from the bottom of the still;

[0014] The above 451g polymer and 25g Pd / Al 2 o 3 The hydrogenation catalyst is put into a reaction kettle with a volume of 1000mL, wherein the mass percentage of palladium in the hydrogenation catalyst is 1.0%, the stirring rate is 750rpm, and the hydrogenation pressure is 2.5MPa, and the temperature is 160°C for 15 hours. Filter at 25°C to obtain 443g of liquid jet fuel.

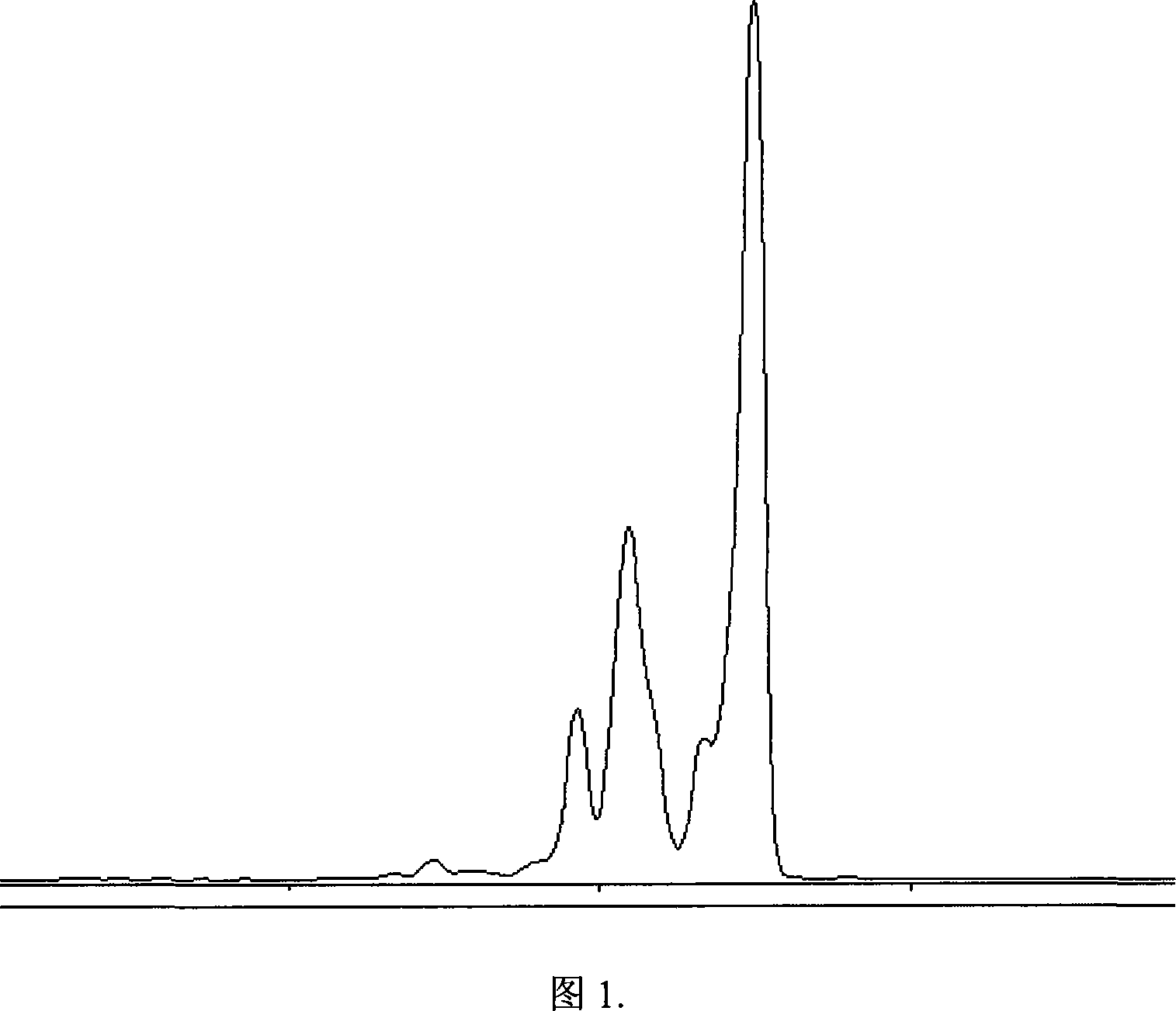

[0015] The synthesized liquid j...

Embodiment 2

[0017] Add 600g of bridged dicyclopentadiene and 60g of HY molecular sieve with a particle size of 0.15 to 0.16mm into a reaction kettle with a volume of 1000mL, stir at 750rpm, and polymerize for 30 hours at a pressure of 3MPa and a temperature of 160°C get the product;

[0018] The product was filtered under reduced pressure, and the filtrate was added to the still, and the unreacted raw materials were evaporated and recovered under the conditions of a pressure of 10kPa and a temperature of 160°C, and 425g of polymer was obtained from the bottom of the still;

[0019] The above 425g polymer product and 66g Pd / Al 2 o 3 Hydrogenation catalyst is put into the reactor that volume is 1000mL, wherein the mass percent of palladium in hydrogenation catalyst is 0.3%, and stirring rate is 850rpm, and hydrogen pressure is that 5MPa, temperature are reacted 20 hours under the condition of 170 ℃, be cooled to 416g of liquid jet fuel was obtained by filtration at 30°C.

Embodiment 3

[0021] Add 150g of cyclopentadiene, 450g of bridged dicyclopentadiene, and 180g of mordenite molecular sieves with a particle size of 0.096-0.106mm into a reaction kettle with a volume of 1000mL. The stirring rate is 900rpm. Under the condition of ℃, the polymerization reaction was carried out for 15 hours to obtain the product;

[0022] The product was filtered under reduced pressure, and the filtrate was added to the still, and the unreacted raw materials were evaporated and recovered under the conditions of a pressure of 8kPa and a temperature of 150°C, and 417g of polymer was obtained from the bottom of the still;

[0023] The above-mentioned 417g polymer and 12g palladium-carbon hydrogenation catalyst are put into a reaction kettle with a volume of 1000mL, wherein the mass percentage of palladium in the hydrogenation catalyst is 5%, the stirring rate is 750rpm, and the hydrogenation pressure is 0.5MPa and the temperature is 180 Under the condition of ℃, react for 10 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com