Gellan gum without organic solvent and production technique thereof

A technology of gellan gum and boiling gum, which is used in the formulation of perfume preparations, medical preparations with non-active ingredients, and pharmaceutical sciences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Organic solvent-free gellan gum preparation process No.1

[0118] Obtain gellan gum-containing fermentation stock solution by conventional methods (such as the method described in Example 1 in Chinese patent application 00125858.3). Prepare gellan gum according to the following process:

[0119] 1) Flocculation: Add 0.5%, 1%, or 3% hydrochloric acid to the fermentation stock solution during stirring, so that the pH is 2.5.

[0120] 2) Dehydration: Pump the flocculated feed liquid into a continuous dehydration press to obtain a filter cake with a water content of about 15-30%.

[0121] 3) Pulping: the filter cake and water are sent to the beater at a ratio of 1:15, and the pasty material liquid is sent to the glue boiling tank;

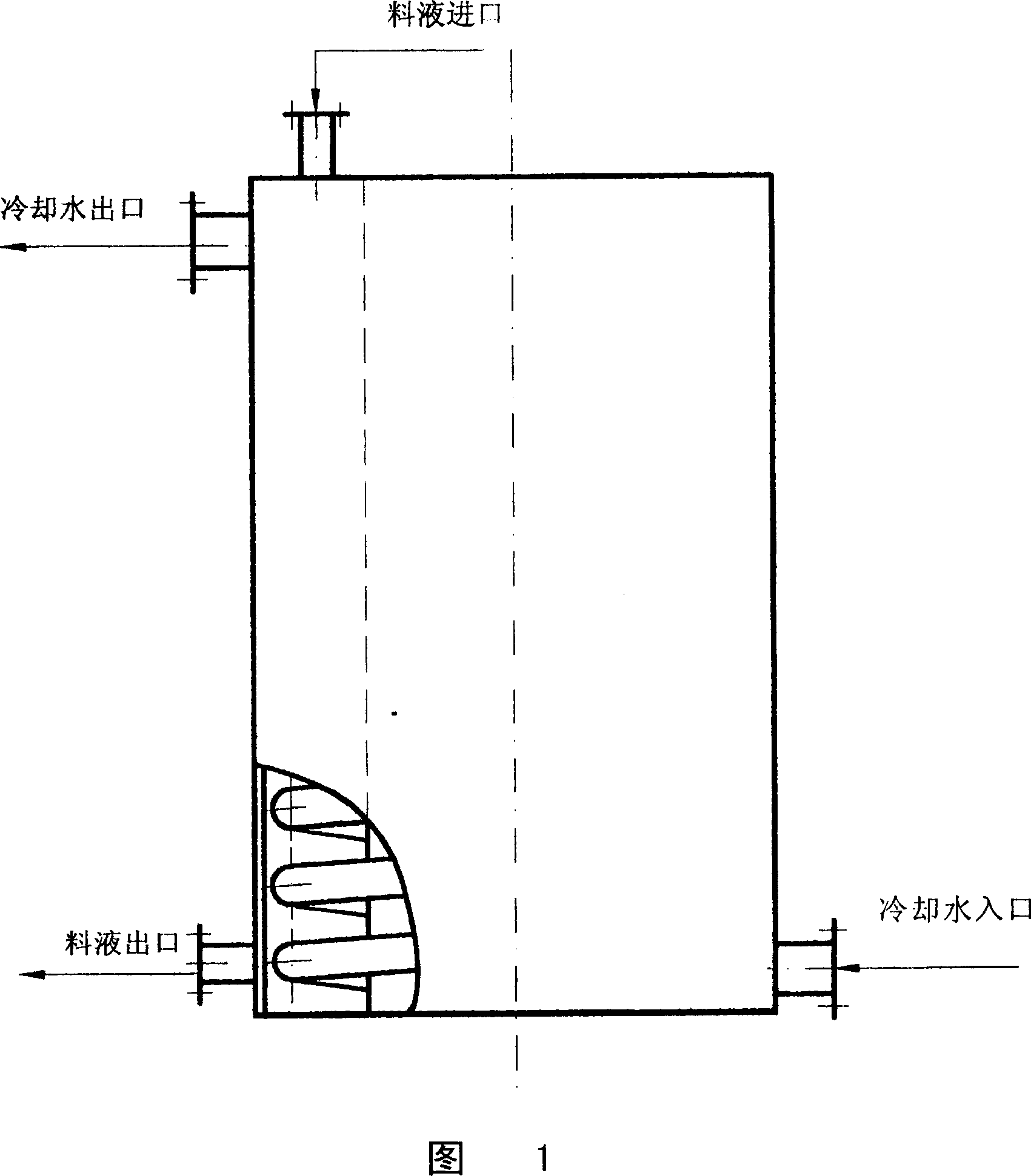

[0122] 4) Glue cooking: Add 2%, 5% or 9% sodium hydroxide solution under stirring until the pH value of the feed solution reaches 6-8. The feed liquid is heated to 70-85°C, and the pH value is adjusted to 8-10. Keep warm for 5-15 minutes, th...

Embodiment 2

[0130] Performance Testing

[0131] For gellan gum No.1 prepared in Example 1, its properties were measured by conventional methods.

[0132] The results are shown in Table 1 below;

[0133] Exterior

[0134] *: Indicates that Escherichia coli was not detected in 100 g of gellan gum.

Embodiment 3

[0136] Organic solvent-free gellan gum preparation process No.2

[0137] Repeat Example 1, the difference is that the gel cooking step conditions are as follows: adjust the pH of the homogenate mixture to pH 6-8, heat to 70-85°C, and boil the gel for 5-15 minutes to obtain the gel boil mixture.

[0138] As a result, gellan gum No. 2 was also obtained.

[0139] Gellan Gum No.2 is detected in the same manner as in Example 2, and the results show that its characteristics are basically the same as Gellan Gum No.1, wherein the residual ethanol cannot be detected (0ppm), and the gel strength is 1070g / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel strength | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com