Triphase AC sliding arc non-balancing plasma sewage treating apparatus

A sewage treatment device and plasma technology, applied in the field of environmental technology and water treatment, can solve the problem of small treatment capacity, no research or report on three-phase AC sliding arc non-equilibrium plasma treatment of sewage, and little research on pollutants, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

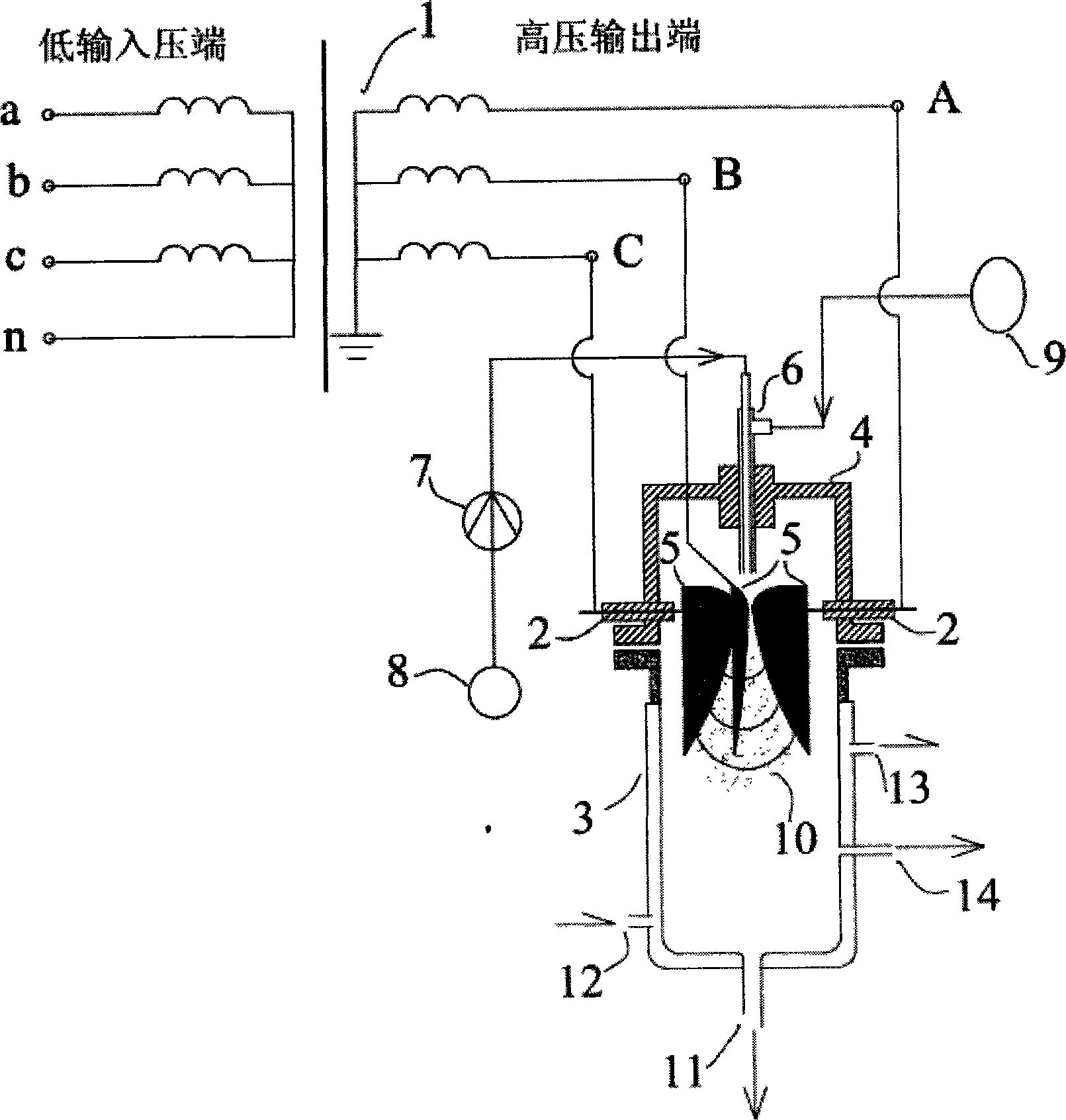

[0045] Referring to the accompanying drawings, the three electrodes 5 are respectively connected to the three phase lines of the three-phase AC plasma power supply, the sewage provided by the sewage source 8 and the gas provided by the carrier gas source 9 pass through the atomizing nozzle 6 to form a gas-liquid mixture and spray it into the water-cooled glass Reactor 3, the gas-liquid mixture flows to the drain end of water-cooled glass reactor 3 through the arcing end with the smallest distance between electrodes.

[0046] In this embodiment, the output voltage of the three-phase AC high-voltage power supply 1 is controlled at 5kV; the three electrodes are all made of metal material stainless steel, the minimum distance between two adjacent electrodes is 2mm, the electrode thickness is 2mm, the length is 100mm, and the width is 30mm; The water-cooled glass reactor 3 has a diameter of 100mm and a volume of 2L; the insulating support 2 and the insulating cover 4 are made of pol...

Embodiment 2

[0049] The device of this embodiment is the same as that of Embodiment 1, and the only difference is that the output voltage of the three-phase AC high-voltage power supply 1 is controlled at 10kV; the gas of the carrier gas source 9 is selected from air and oxygen respectively, and the flow rate is controlled at 800L / h; the sewage source 8 Azoic acid orange 7 was used to simulate printing and dyeing wastewater. The experimental conditions, test data and results are shown in Table 2.

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com