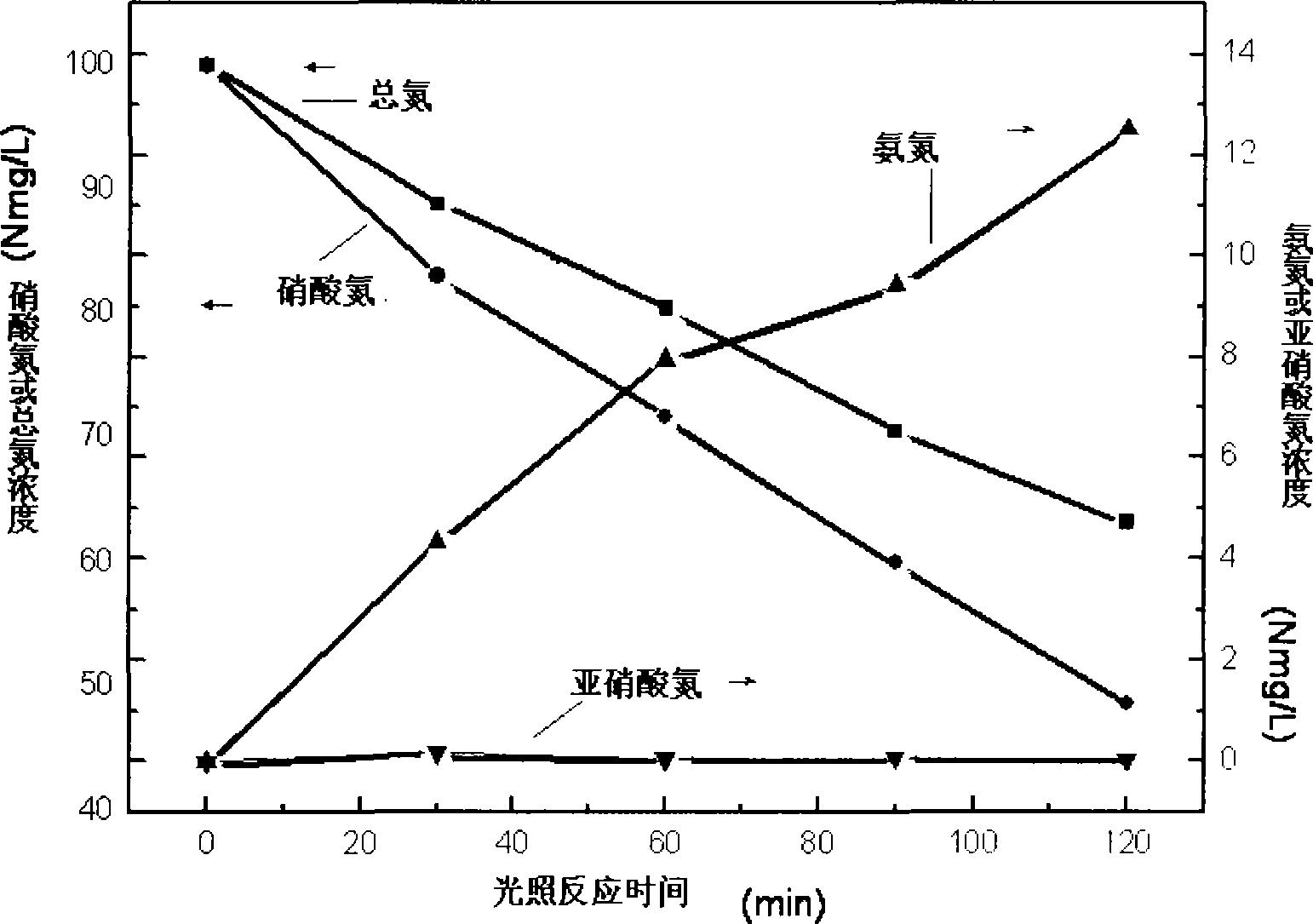

Process of catalytically reducing nitrate nitrogen in water with Fe0/TiO2

A technology of nitrate nitrogen and photocatalysis, applied in chemical instruments and methods, reduced water/sewage treatment, physical/chemical process catalysts, etc., can solve the problems of high price of doping precious metals, high yield of ammonia nitrogen, low efficiency of reducing nitrate nitrogen, etc. problem, to achieve the effect of low price and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Fe 0 / TiO 2 Preparation: Weigh 1.00 g of P-25 titanium dioxide activated in a muffle furnace at 300° C. for 1 h. Add a certain amount of ferrous sulfate heptahydrate, add deionized water to make the volume to 50mL, ultrasonically disperse for 20min, then pass nitrogen for 30min, add stoichiometric sodium borohydride, continue to pass nitrogen for 30min, and centrifuge the precipitate. Wash three times with water and ethanol respectively. Vacuum drying at 60° C. in a vacuum oven to obtain the desired composite catalyst powder particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com