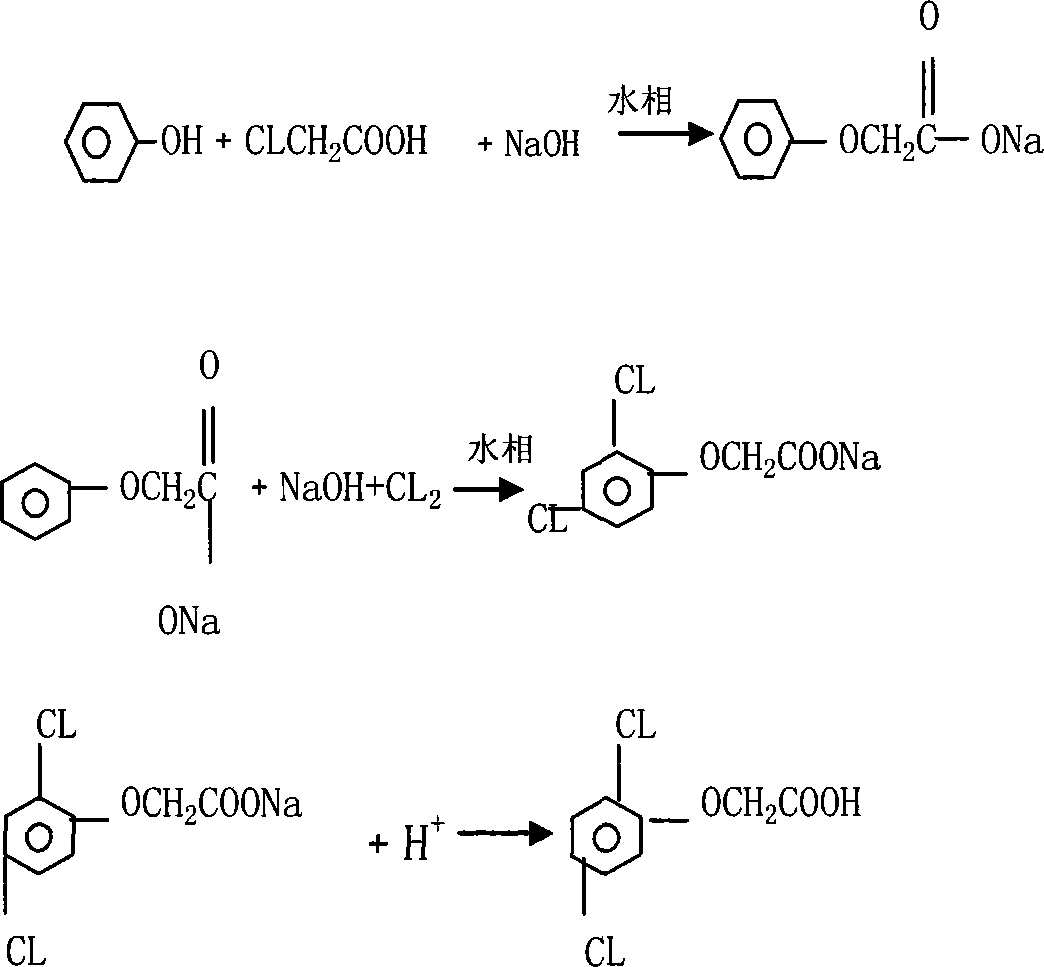

Synthesis of 2,4-D

A synthetic method, etherification technology, applied in 2 fields, can solve the problems of heavy pollution, unfavorable clean production, waste of water resources, etc., and achieve the effect of high conversion rate, less pollution and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

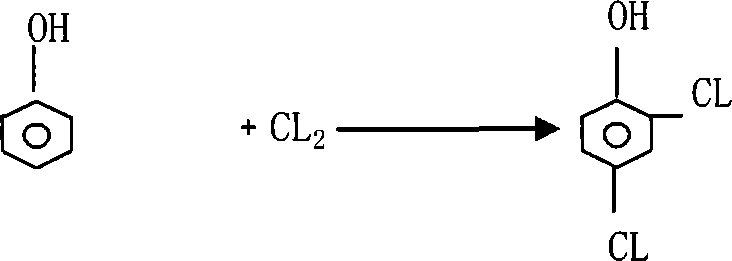

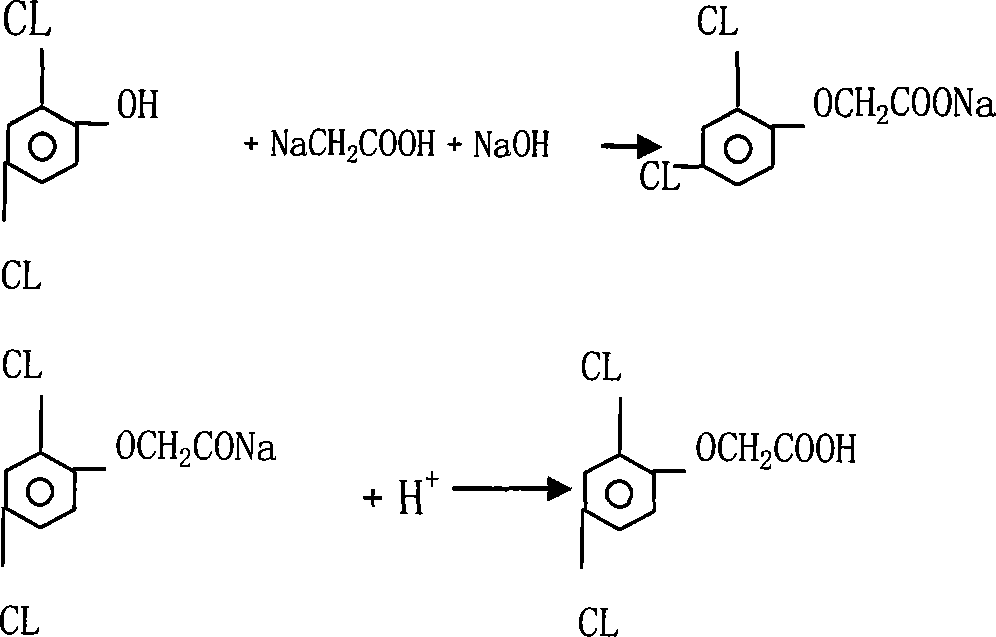

Method used

Image

Examples

Embodiment 1

[0021] Drop into 500g saturated brine in the 1000ml four-port flask with agitation and reflux condenser (the second batch starts to use synthetic mother water) and drops into 94g of phenol (99.5% in content), 96g of chloroacetic acid (98%) is warming up to 70°C, and divides Add 85g (96%) of flaky sodium hydroxide in batches. After the addition, heat up to reflux and keep for 3-8 hours. 30g of water will be released in the later stage of heat preservation. (The water generated by the reaction) may not be dehydrated. After the reaction is over, cool to 60°C , pass in hydrogen chloride gas, adjust the system to PH = 1~2, then add 300ml of dichloroethane, static layering, keep the temperature at 30 ° C ~ 70 ° C, the lower layer is salt water, the middle layer is saturated brine, put down the salt layer, and drain Obtain the by-product sodium chloride product, the filtrate and the water layer are combined to separate the saturated brine, collect (for the next batch of applications),...

Embodiment 2

[0023] Use the mother water of Example 1 to apply mechanically, weigh 500g of the mother water and process it according to the method of Example 1 to obtain 210g of the product with a content of 98% and a yield of 93%. The reaction mother water is applied again to obtain 216g of the product with a content of 98% and a yield of 95.8%. Recycling Sodium chloride 115g.

Embodiment 3

[0025] The synthesis method is the same as Example 2. After etherification, it is acidified with hydrogen chloride or sulfuric acid, cooled to 50-85 °C, filtered, the solid is etherified, washed with a small amount of hot water to remove phenol and chloroacetic acid, and the washing water is combined into brine for the next batch. , the washed solid was dissolved in ethylene dichloride, fed with chlorine gas for reaction, and processed according to the method of Example 1 to obtain 215 g of the product, with a content of 98% and a yield of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com