Production of coarsening electrode for high-brightness packed LED chip and vertical LED chip

A high-brightness, metal electrode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as reducing the external quantum efficiency of LED devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

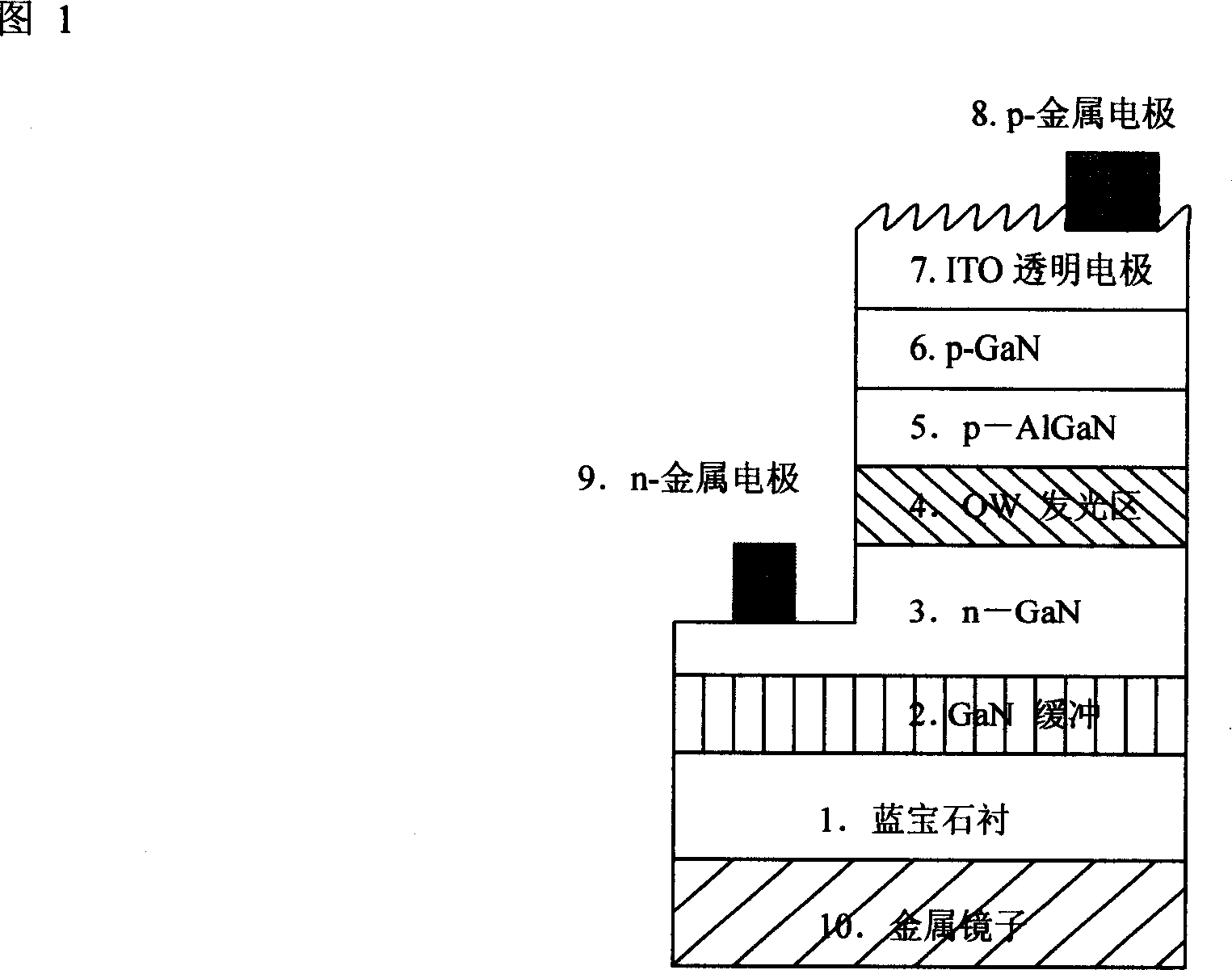

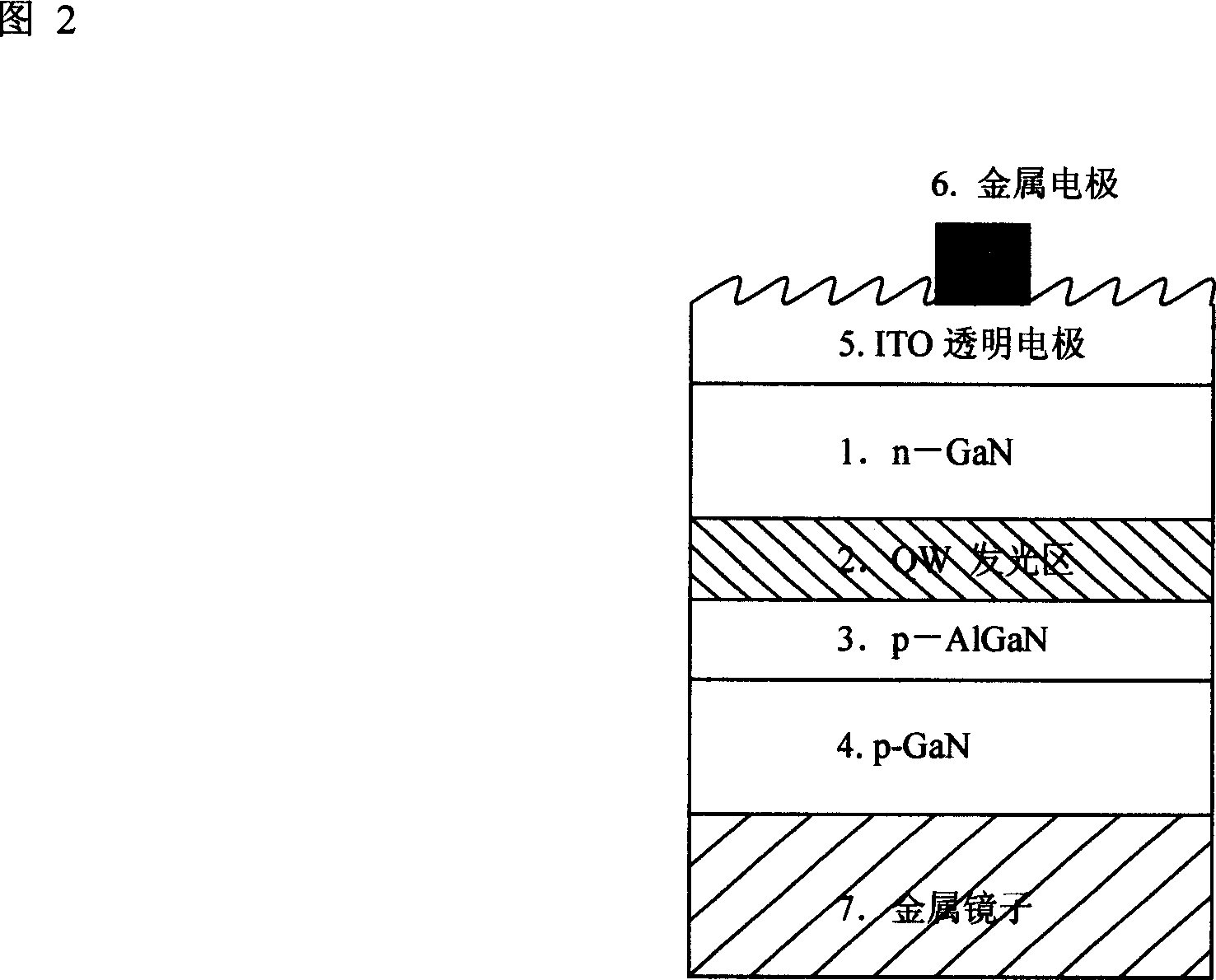

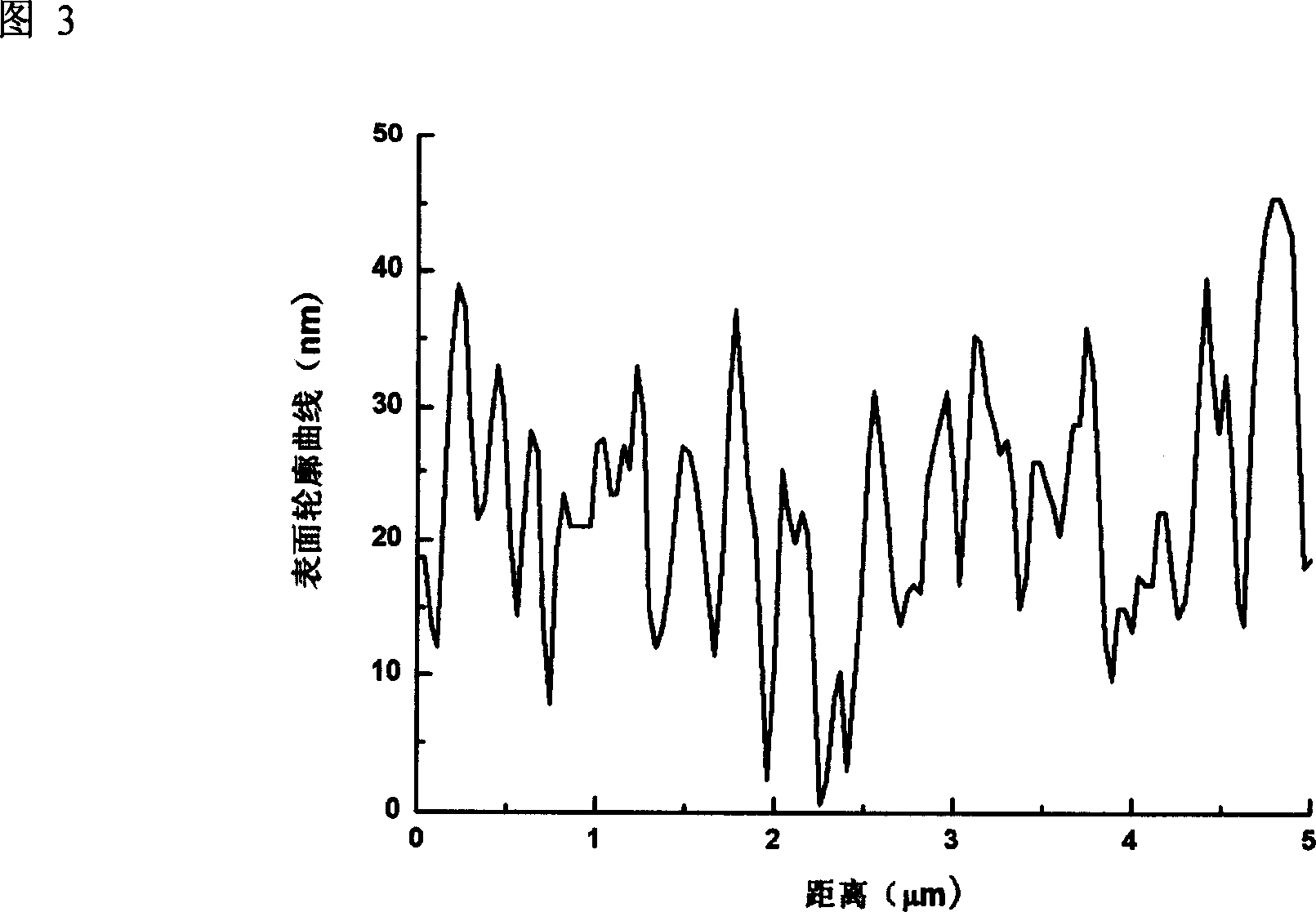

[0012] One of the novel light-emitting diodes of the present invention, comprising a sapphire substrate 1, a GaN buffer layer 2, an n-type GaN layer 3, an InGaN / GaN multiple quantum well (MQWs) active layer (light-emitting layer) 4, and a p-AlGaN waveguide layer 5 , p-type GaN layer 6, p-type ohmic-contact transparent electrode 7, p-type ohmic-contact transparent electrode 8, n-type ohmic-contact electrode 9 and metal layer mirror 10. ITO is used as the material, and the surface of the ITO film is roughened by natural lithography and dry etching.

[0013] In order to realize the above-mentioned light-emitting diodes, a method for preparing a high-brightness light-emitting diode of the present invention comprises the following steps:

[0014] (1) Using MOCVD epitaxy to grow GaN-based LED structure epitaxial wafers, the lower lining is blue sapphire (Al 3 o 2 );

[0015] (2) Deposit ITO film on the epitaxial wafer by electron beam evaporation;

[0016] (3) Apply natural lith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com