Cobalt-nickel-iron-gallium shape memory alloy material

A memory alloy, iron gallium technology, applied in the field of cobalt-nickel-iron-gallium shape memory alloy materials, can solve the problems of small brittleness, difficult processing and deformation, and inability to be practically applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

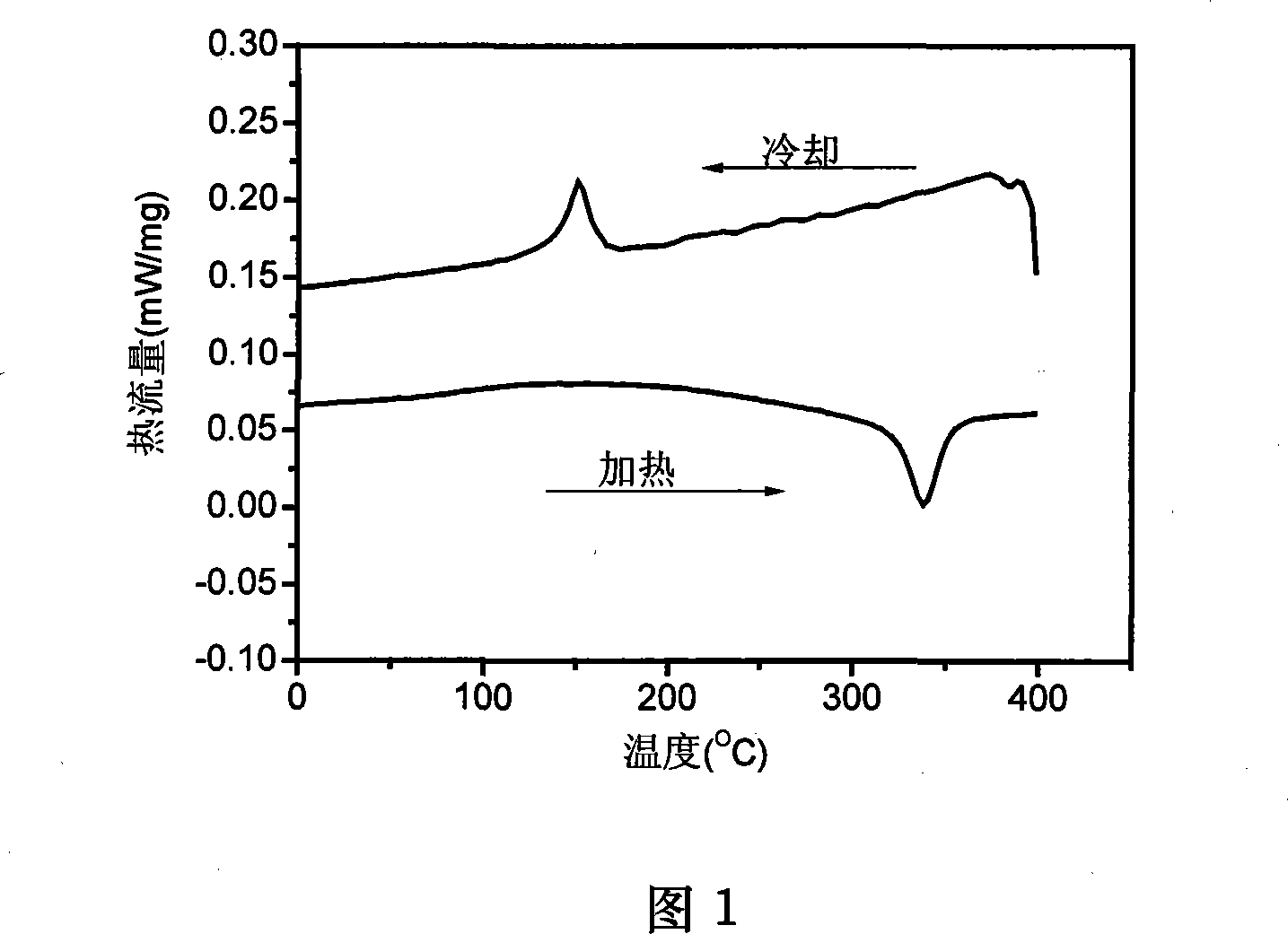

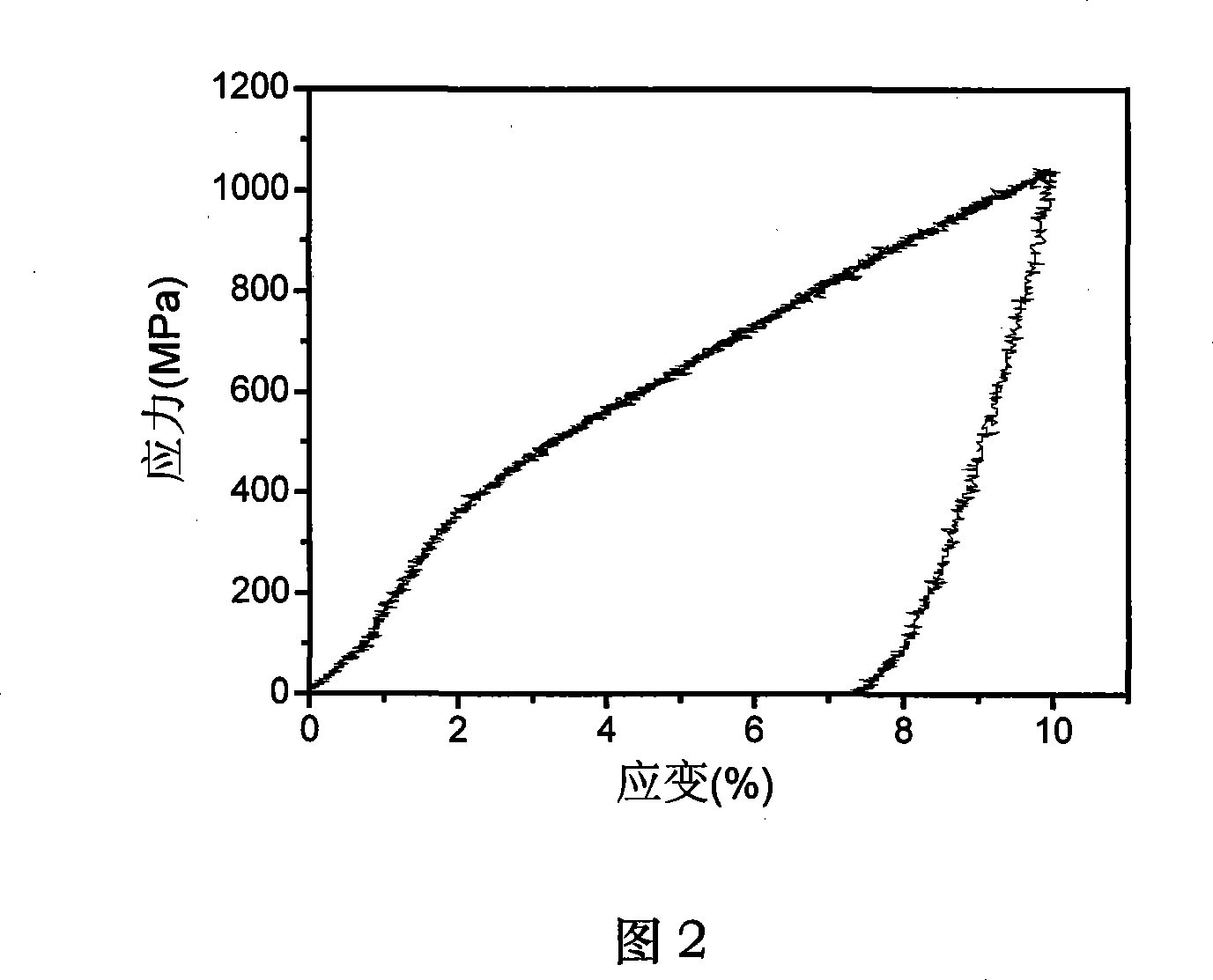

[0035] Example 1: Making 50g Co 46 Ni 23 Fe 2 Ga 29 Shape memory alloy material

[0036] Step 1: Weighing and proportioning

[0037] Press Co 46 Ni 23 Fe 2 Ga 29 Atomic ratio weighed 21.9 grams of cobalt with a purity of 99.9%, 10.9 grams of nickel with a purity of 99.9%, 0.9 grams of iron with a purity of 99.9%, and 16.3 grams of gallium with a purity of 99.99%.

[0038] Step 2: smelting, casting rod

[0039] Put the weighed nickel, manganese, iron, and gallium blocks into a non-consumable vacuum arc furnace, and vacuumize to 3×10 -3 Pa, filled with high purity argon to 0.7×10 5 Pa.

[0040] Then, the raw materials are smelted repeatedly at 1800℃ for 4 times to make the composition uniform and make Co 46 Ni 23 Fe 2 Ga 29 Shape memory alloy ingots;

[0041] The above-mentioned ingot is melted at 1800°C and directly poured into a water-cooled copper mold of a non-consumable vacuum electric arc furnace; a rapidly solidified cast rod with a diameter of 5 mm is made.

[0042] Step 3: ...

Embodiment 2

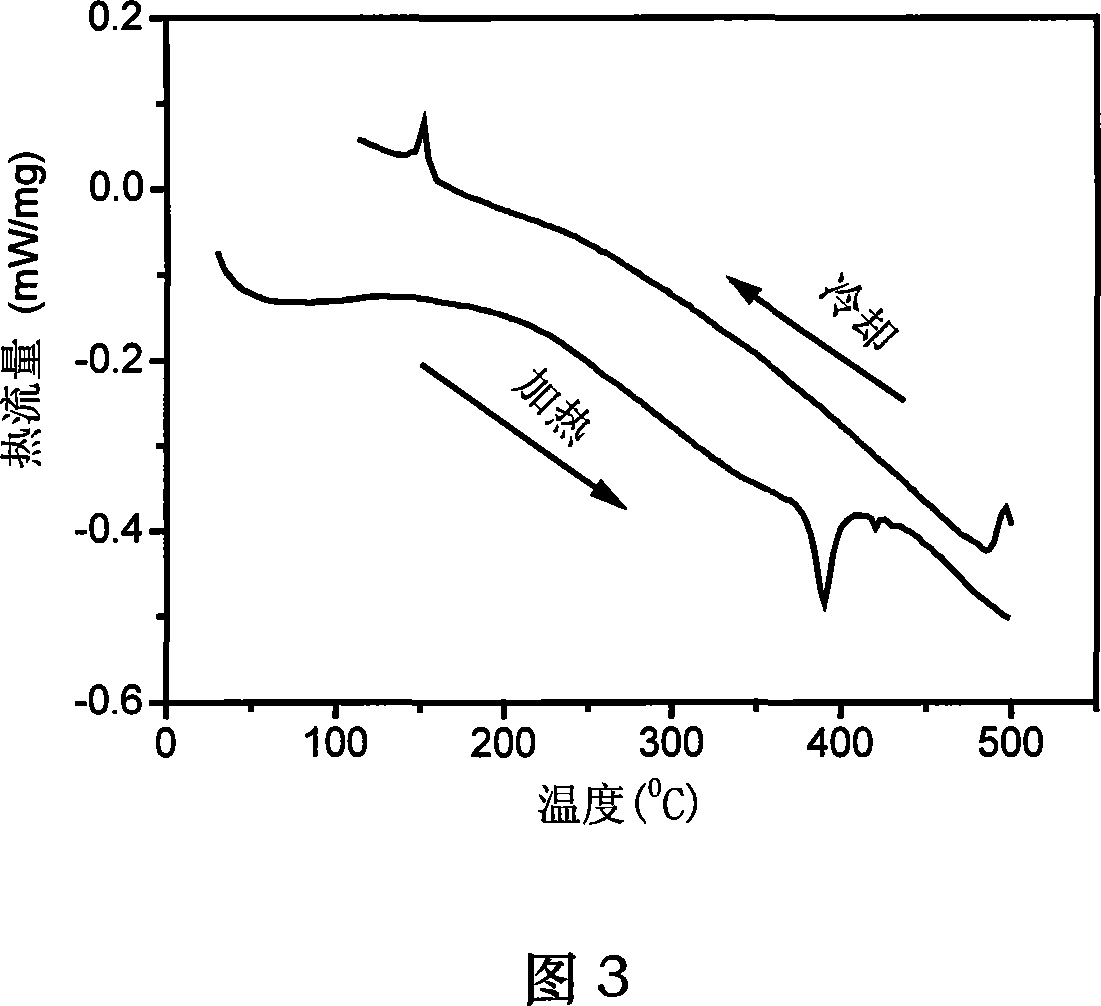

[0048] Example 2: Making 50g Co 46 Ni 19 Fe 6 Ga 29 Shape memory alloy material

[0049] Step 1: Weighing and proportioning

[0050] Press Co 46 Ni 19 Fe 6 Ga 29 Atomic ratio weighed 21.9 grams of cobalt with a purity of 99.9%, 9.0 grams of nickel with a purity of 99.9%, 2.7 grams of iron with a purity of 99.9%, and 16.3 grams of gallium with a purity of 99.99%.

[0051] Step 2: smelting, casting rod

[0052] Put the weighed nickel, manganese, iron, and gallium block materials into the non-consumable vacuum electric arc furnace and vacuumize to 5×10 -3 Pa, filled with high purity argon to 0.7×10 5 Pa;

[0053] Then, the raw materials are smelted 5 times at 2000℃ to make the composition uniform and make Co 46 Ni 19 Fe 6 Ga 29 Shape memory alloy ingots;

[0054] Then add the above Co 46 Ni 19 Fe 6 Ga 29 After the shape memory alloy ingot is melted at 2000°C, it is directly poured into the water-cooled copper mold of the non-consumable vacuum arc furnace; a rapidly solidified cast ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com