Zinc-cathode material and zinc cathode and zinc secondary cell including this zinc cathode material

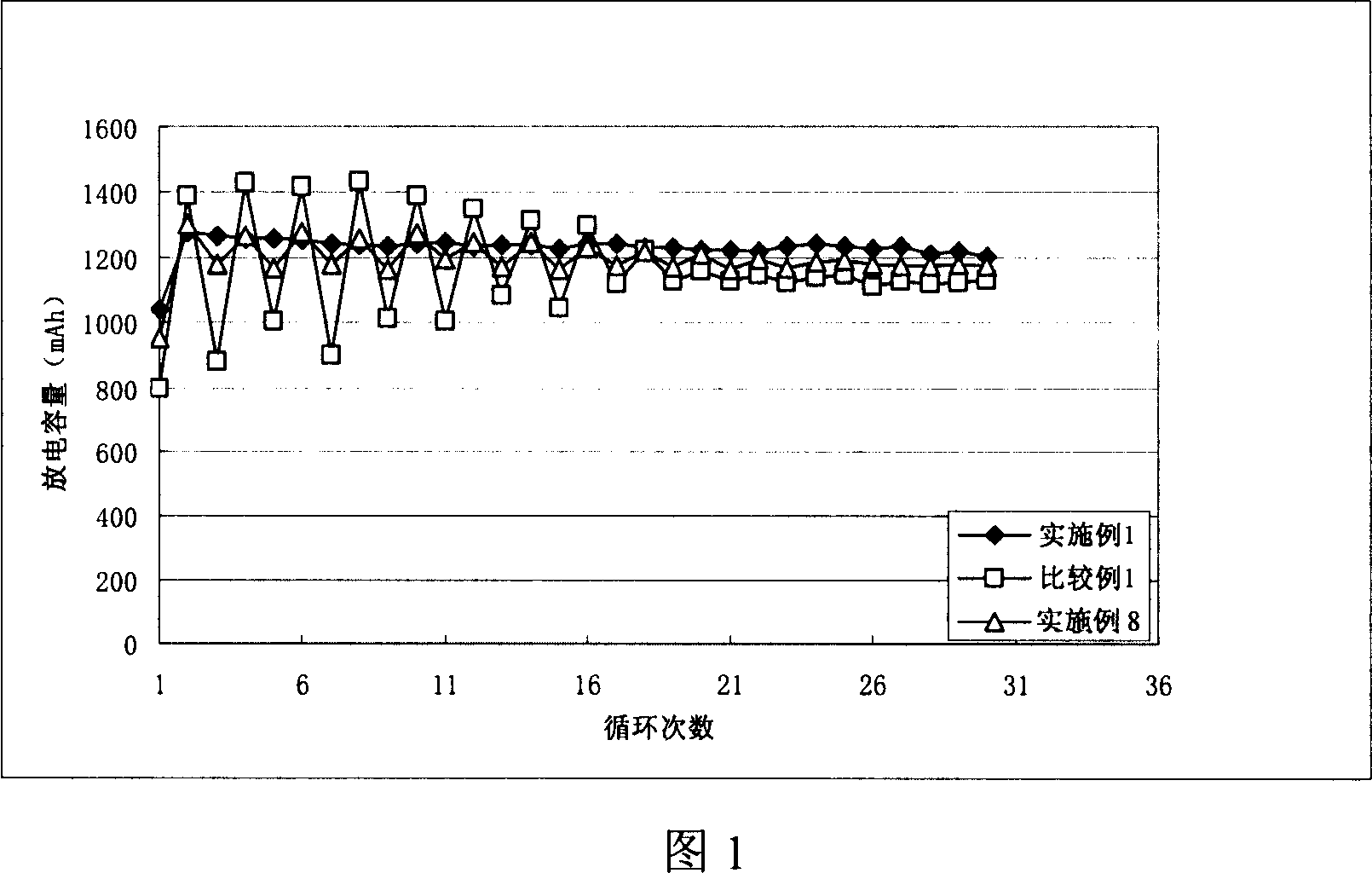

A negative electrode material and secondary battery technology, which is applied in the direction of battery electrodes, alkaline storage batteries, alkaline storage battery electrodes, etc., can solve the problems of high and low discharge capacity of batteries, large fluctuations, etc., to achieve stable discharge capacity, suppress deformation, Effect of suppressing discharge capacity fluctuation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This example is used to illustrate the zinc negative electrode material provided by the present invention, the zinc negative electrode containing the material, the zinc-nickel secondary battery and the preparation method thereof.

[0028] 78 grams of zinc oxide with an average particle diameter of 5 microns, 2 grams of calcium hydrogen phosphate with an average particle diameter of 2 microns, 1 gram of calcium metaphosphate with an average particle diameter of 1.5 microns, and 14 grams of magnesium bismuth with an average particle diameter of 4 microns The alloy powder is evenly mixed in a beaker, wherein the content of magnesium in the magnesium-bismuth alloy is 6% by weight. Then add 20 grams of concentration of 1.6% by weight of hydroxypropyl methylcellulose solution and 24 grams of concentration of 2% by weight of polyvinyl alcohol solution, fully stir, then add 5 grams of concentration of 60% by weight of polytetrafluoroethylene Ethylene suspension, stirred to obta...

Embodiment 2

[0032] This example is used to illustrate the zinc negative electrode material provided by the present invention, the zinc negative electrode containing the material, the zinc-nickel secondary battery and the preparation method thereof.

[0033] 75 grams of zinc oxide with an average particle diameter of 4.5 microns, 5 grams of calcium hydrogen phosphate with an average particle diameter of 2.5 microns, and 15 grams of magnesium-copper-tin alloy powder with an average particle diameter of 7 microns are uniformly mixed in a beaker. The content in the copper-tin alloy is 27% by weight. Then add 20 grams of concentration of 1.6% by weight of hydroxypropyl methylcellulose solution and 24 grams of concentration of 2% by weight of polyvinyl alcohol solution, fully stir, then add 5 grams of concentration of 60% by weight of polytetrafluoroethylene Ethylene suspension, stirred to obtain a uniform slurry, the slurry is coated on both sides of the tin-plated punched copper strip with a ...

Embodiment 3

[0037] This example is used to illustrate the zinc negative electrode material provided by the present invention, the zinc negative electrode containing the material, the zinc-nickel secondary battery and the preparation method thereof.

[0038] 80 grams of zinc oxide with an average particle diameter of 2 microns, 7 grams of calcium metaphosphate with an average particle diameter of 1.5 microns, and 8 grams of magnesium-manganese-copper alloy powder with an average particle diameter of 11 microns are uniformly mixed in a beaker, wherein magnesium is mixed with magnesium The percentage content in the manganese-copper alloy is 10% by weight, and the percentage content of copper in the magnesium-manganese-copper alloy is 5% by weight. Then add 20 grams of concentration of 1.6% by weight of hydroxypropyl methylcellulose solution and 24 grams of concentration of 2% by weight of polyvinyl alcohol solution, fully stir, then add 5 grams of concentration of 60% by weight of polytetrafl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com