Petroleum annular tube reducer union and production process

A technology of reducing joint and manufacturing process, which is applied in casing, drilling pipe, earthwork drilling and other directions, can solve the problems of low work efficiency and yield, cannot adapt to reducing joint, and cannot meet supporting requirements, etc., to improve work efficiency. Efficiency and yield, reduce own weight, reduce consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

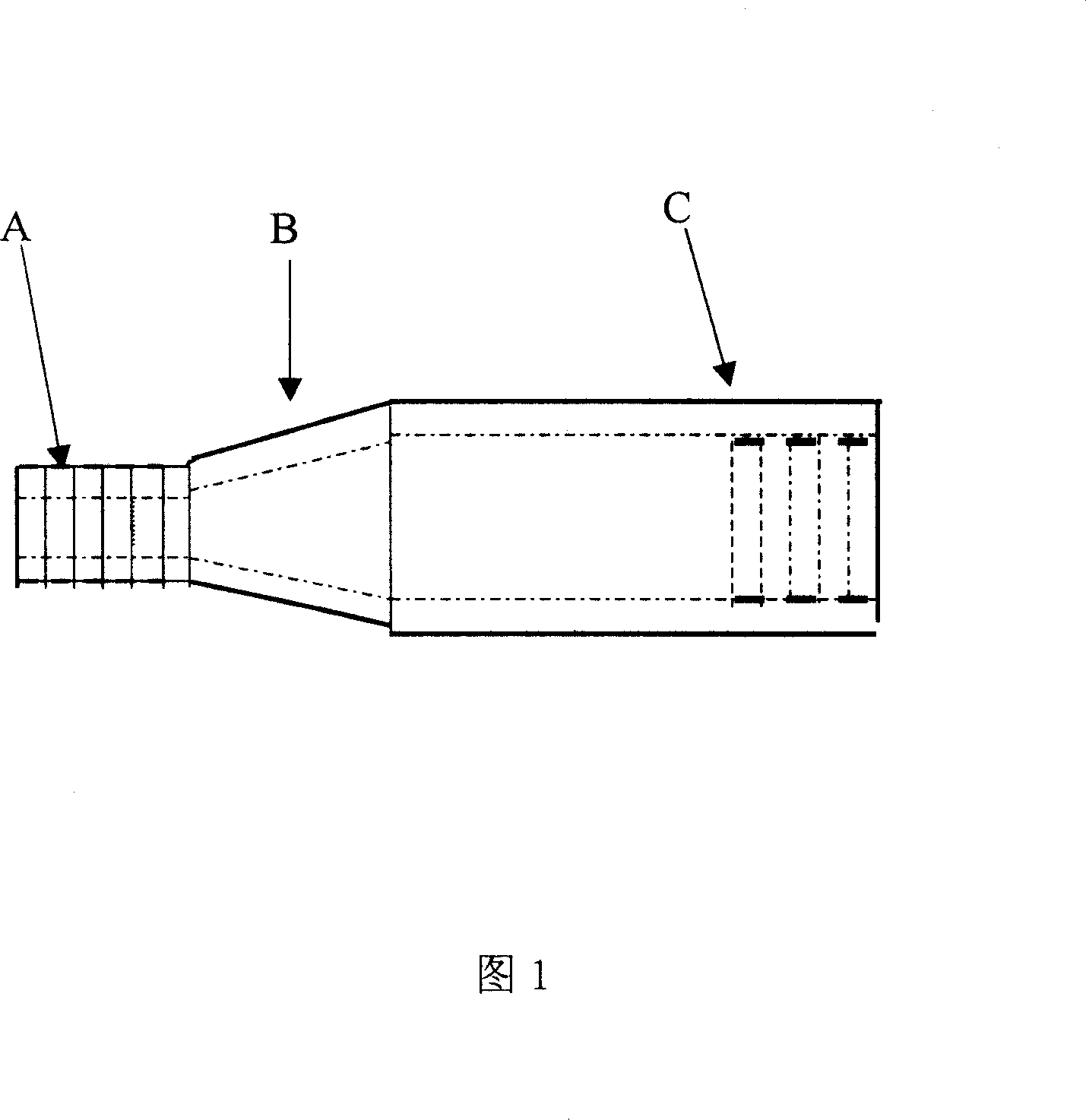

[0012] The implementation of the present invention will be further described below in conjunction with accompanying drawing 1 .

[0013] The invention provides a manufacturing process for oil casing variable diameter joints. The process uses coupling material steel pipes matched with petroleum casings as raw materials to directly manufacture a complete set of manufacturing processes for oil casing variable diameter joints.

[0014] The manufacturing process of the present invention comprises: thermal expansion preparation process and thermal shrinkage preparation process, above-mentioned two kinds of process steps are as follows:

[0015] (1) The thermal expansion process is carried out according to the following steps:

[0016] (1) Select the raw material pipe: select the steel pipe as the raw material pipe according to the material required by the design and the small head specification of the finished product of the variable diameter joint;

[0017] (2) Making pipe materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com