Method for measuring material acoustics non-linear coefficient using rayleigh surface wave

A technology of nonlinear coefficients and surface waves, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, generation of ultrasonic waves/sonic waves/infrasonic waves, and measurement devices, which can solve the problem of inability to guarantee accurate and reliable measurement results and are not suitable for acoustic nonlinearity Coefficient measurement and other issues, to achieve the effect of simple and easy measurement process, restrain the influence of random factors, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] To use Rayleigh surface waves to measure the acoustic nonlinear coefficients of aluminum alloys AA2024 and AA6061, the specific implementation steps are:

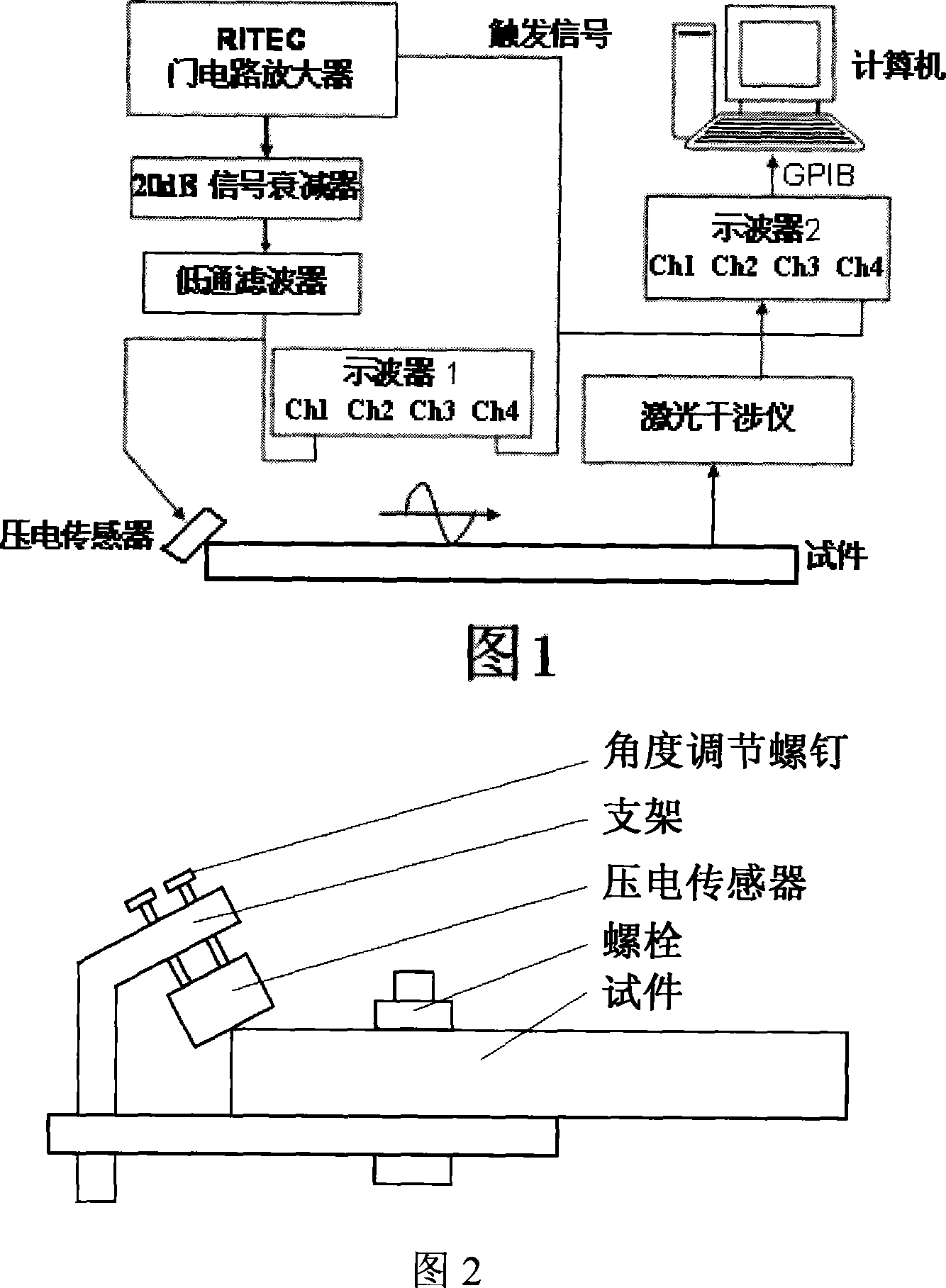

[0025] (1) Excitation of Rayleigh surface waves: After carefully polishing and polishing the surface of the specimen made of aluminum alloy AA2024, grease is used as the coupling agent between the piezoelectric sensor and the specimen, as shown in Figure 2. The piezoelectric sensor is fixed on the bracket by bolts, and the piezoelectric sensor is in close contact with the edge of the specimen through the angle adjustment screw. Adjust the angle adjustment screw to maximize the intensity of the excited Rayleigh wave. As shown in Figure 1, the RITEC RAM-5000Mark IV gate circuit signal amplifier is used as the signal source to generate the signal, and the period of the output sine pulse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com