Method for copying surface basso-relievo microstructure based on Darman raster

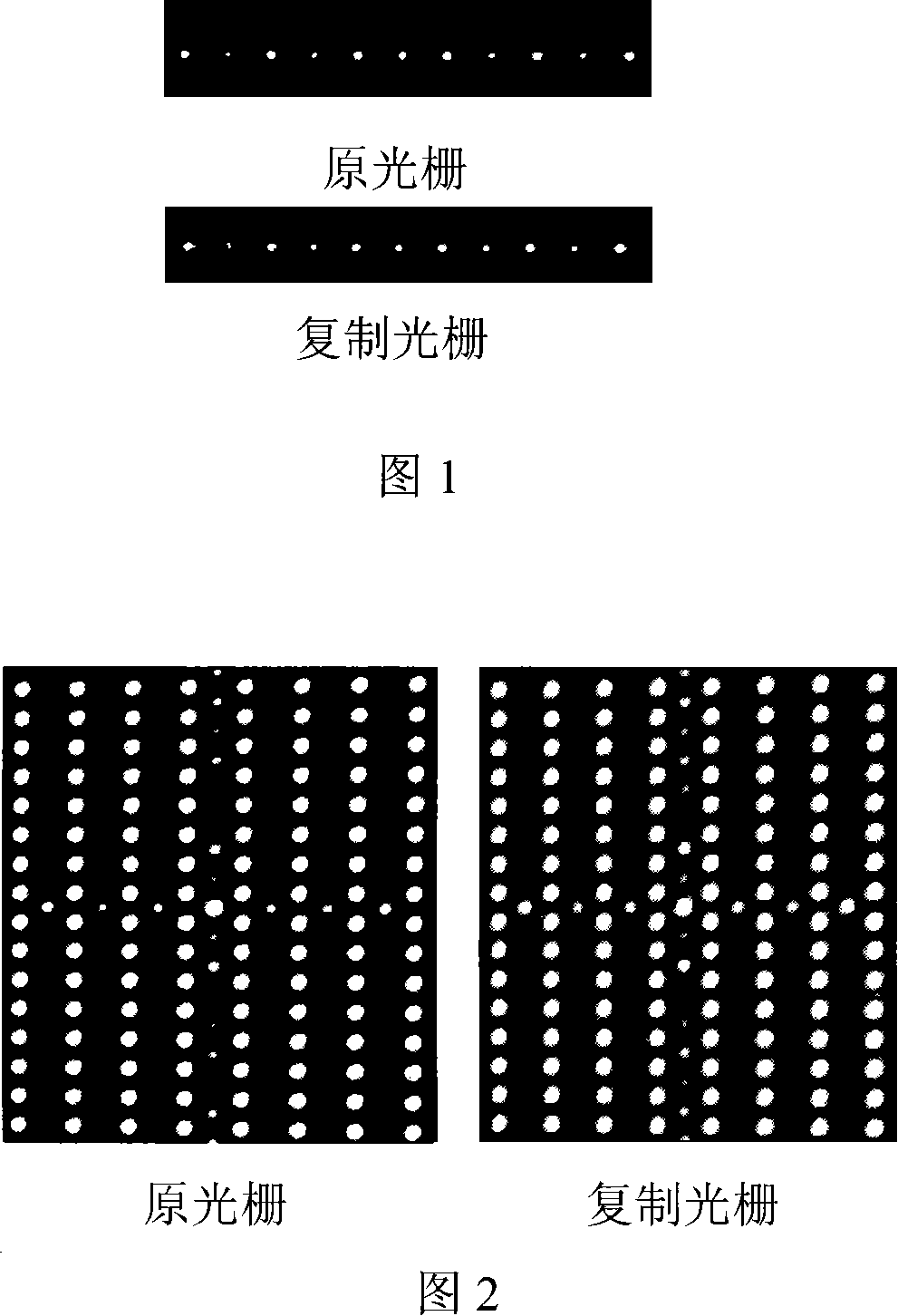

A technology of Damman grating and duplication method, which is applied in the duplication field of surface relief microstructure Damman grating, can solve the problems of high shrinkage rate of sol-gel material, complicated process, incomplete optical properties of grating and grating, etc., and achieves good physical properties. Effects of chemical stability, reduced manufacturing cost, excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] We use polydimethylsiloxane (polydimethylsiloxane, Sylgard184, Dow Coring) to make the grating mold. Proportional mixing, stirring evenly, if bubbles are generated, vacuum defoaming treatment is required. The time of vacuum defoaming depends on the amount of bubbles mixed in during the stirring process; after defoaming is completed, evenly coat polydimethylsiloxane on the The surface of the Mann grating, and then cured at room temperature for 48 hours or at high temperature. High temperature curing can shorten the curing time. We cure at 90°C for one hour. and Damman gratings can be easily separated.

[0039] After obtaining the polydimethylsiloxane mold, the Damman grating can be replicated on the UV adhesive. We use a low viscosity UV adhesive (NOA61, Norland) as the material for replicating the grating. The viscosity coefficient is 300 centipoise and the hardness is 8. First drop a drop of NOA61 on a clean glass substrate, and imprint the polydimethylsiloxane mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com