Detection system for safety self-breaking type injector assembling machine

A detection system and assembly machine technology, applied in the direction of syringes, hypodermic injection devices, infusion sets, etc., can solve the problems of needle seat pollution, low stability, low speed, etc., achieve smooth and smooth operation, reduce artificial pollution, and guarantee finished products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

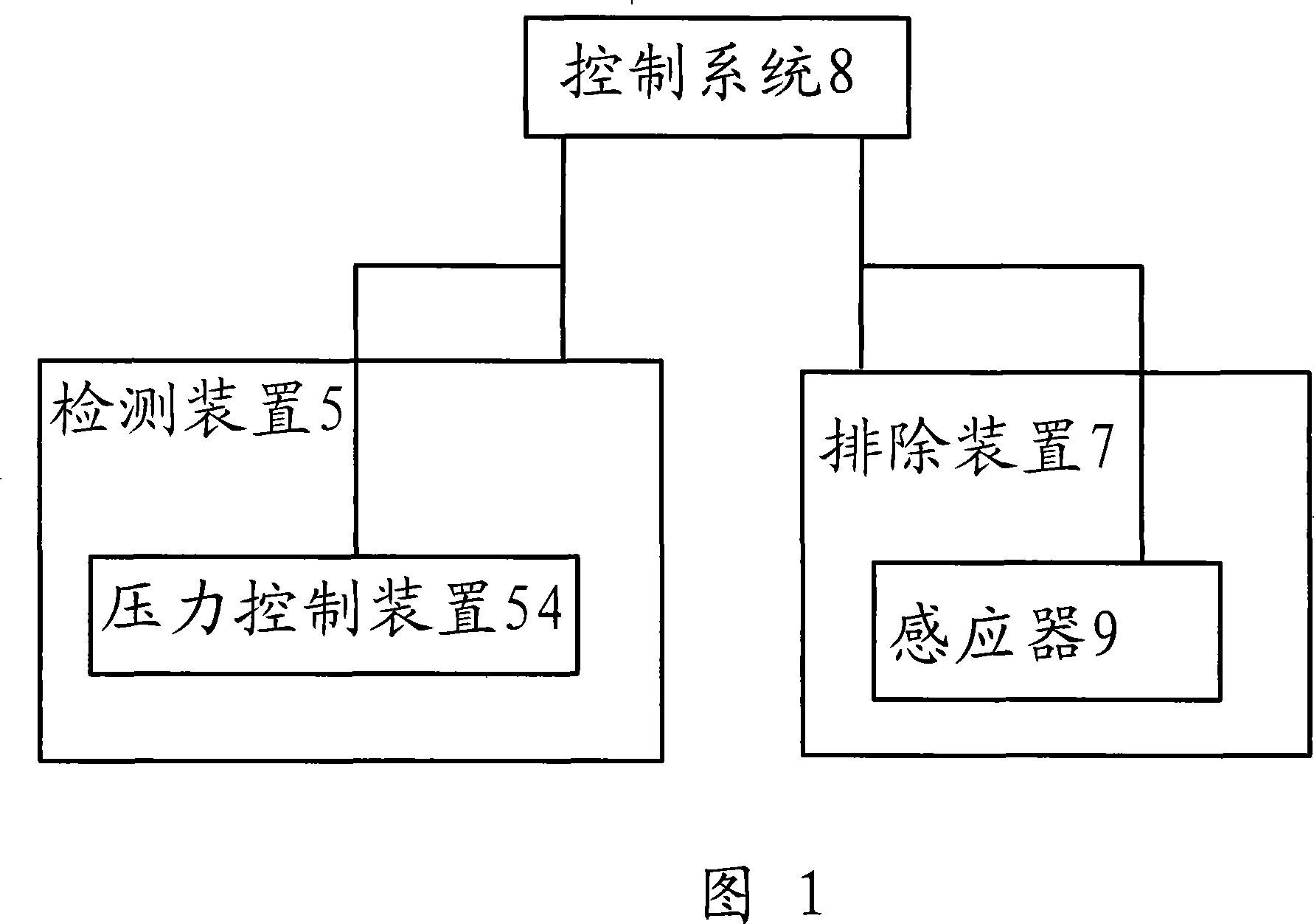

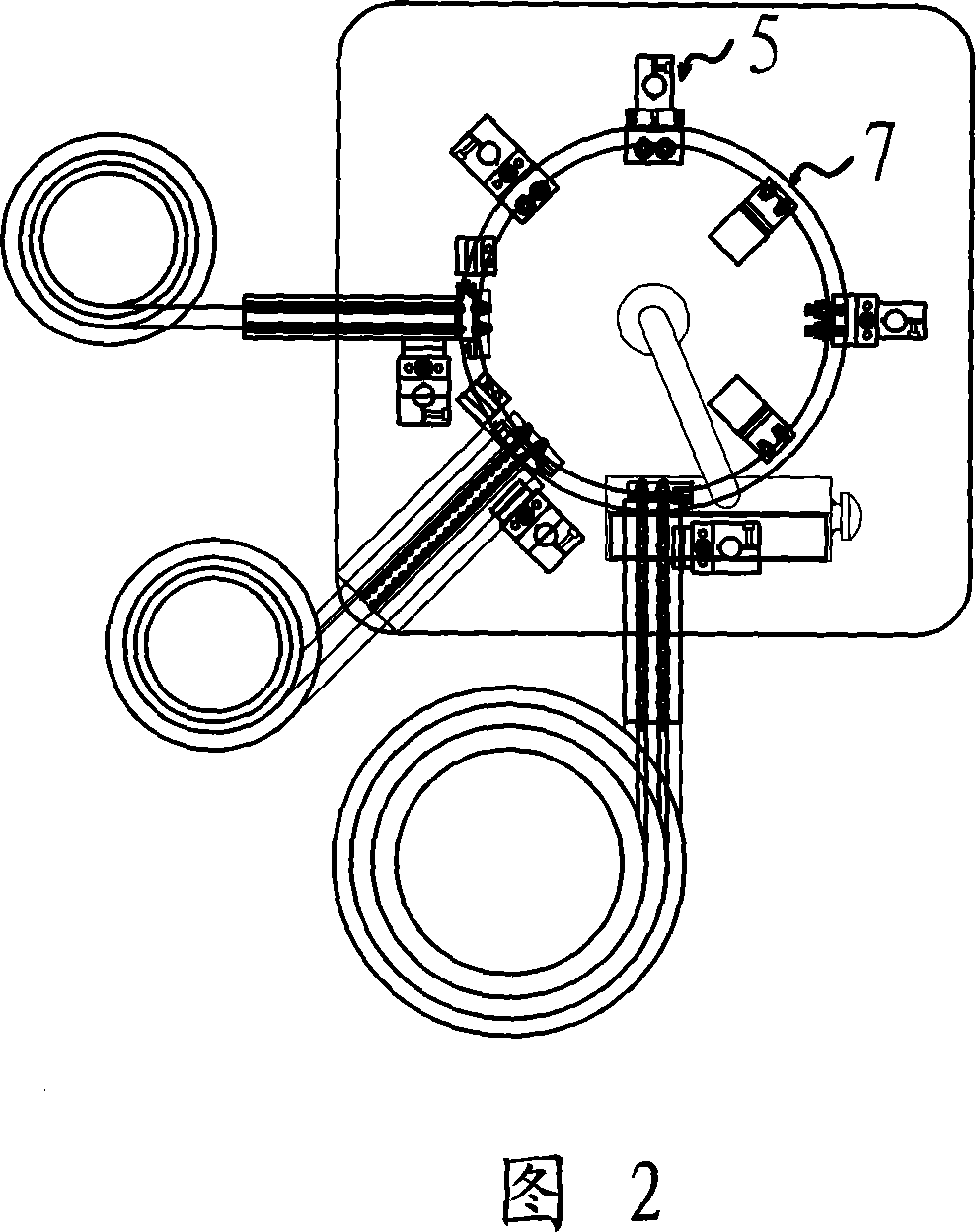

[0038]As shown in Figures 1 and 2, the detection system of the safety self-destructing syringe assembly machine includes a rotating shaft 1, a turntable 2, a detection device 5, an exclusion device 7, a control system 8, a pressure control device 54, and a sensor 9. .

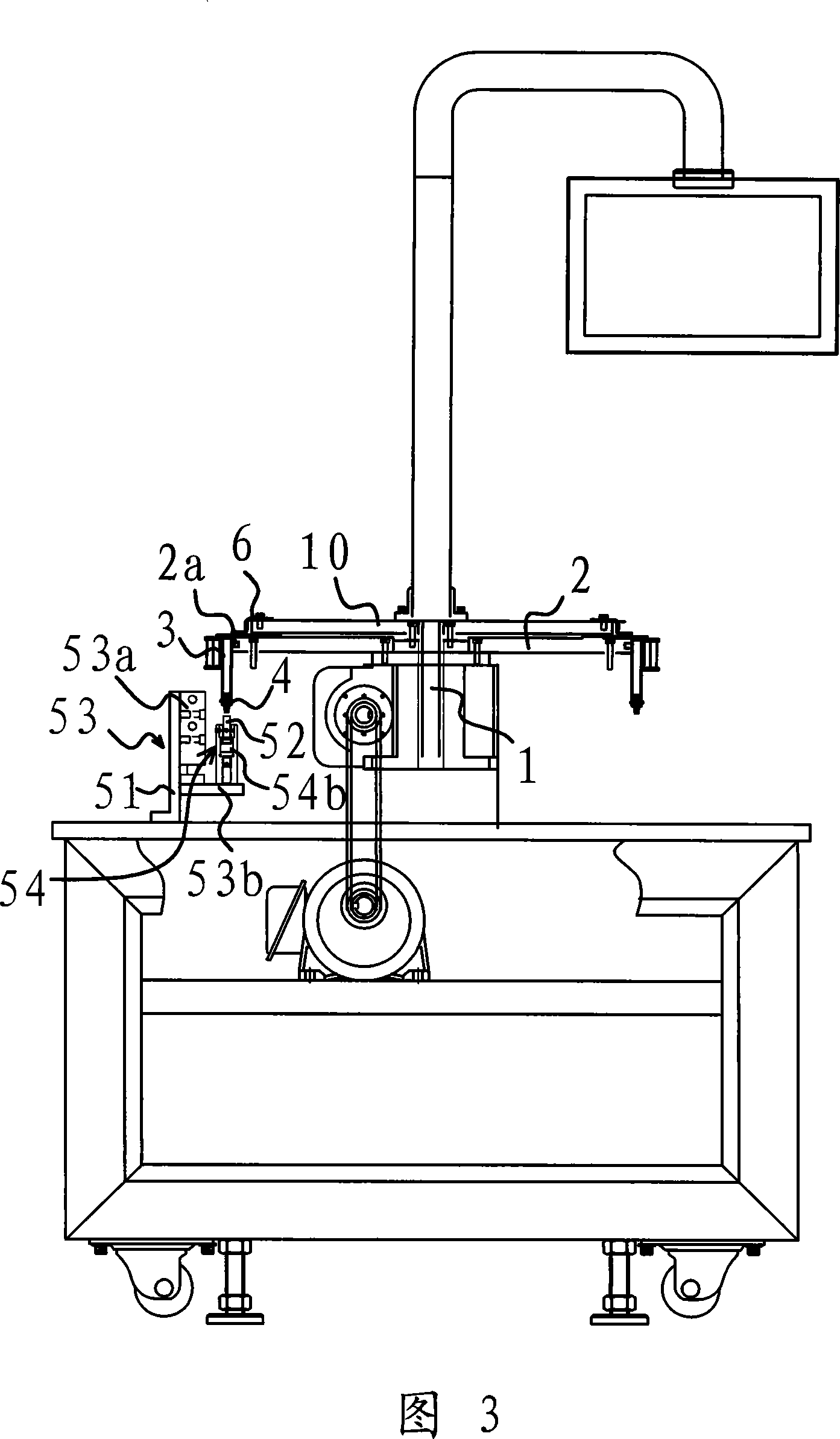

[0039] As shown in Figure 2, the detection system is set on a safety self-destruct syringe assembly machine. It includes a rotating shaft 1 on which a turntable 2 that can rotate together with the rotating shaft 1 is fixed, and several notches 2a for fixing the cylinder 3 are evenly distributed on the edge of the turntable 2 . Below the notch 2a is provided a defective product detection device 5 for applying an upward force to the needle holder 4 installed...

Embodiment 2

[0047] As shown in Figures 5 and 6, in this embodiment, the pressure control device 54 is a spring 54a, one end of the spring 54a acts on the top block 52, and the other end acts on the elevating frame 53b. The rest are the same as in Example 1, and will not be described in detail herein.

Embodiment 3

[0049] As shown in Figures 7 and 8, in this embodiment, the lifting mechanism 53 includes a servo motor 53c fixed on the bracket 51, and the motor shaft of the servo motor 53c is fixedly connected with a screw rod 53d through a coupling 53f , on the screw rod 53d, a vertical moving block 53e is threadedly connected, the above-mentioned top block 52 is fixedly connected on the vertical moving block 53e, and the top block 52 is provided with a mechanism for controlling the force of the top block 52 on the needle hub 4 Pressure control device 54. The pressure control device 54 is a pressure sensor 54b, and its working principle is that when the silicon piezoresistive element is bent and deformed by an external force, the resistance will change accordingly, thereby adjusting the rotation speed of the servo motor 53c. The moving speed of the lifting mechanism 53 is controlled by adjusting the servo motor 53c through the force touched by the pressure sensor 54b. The servo motor 53c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com