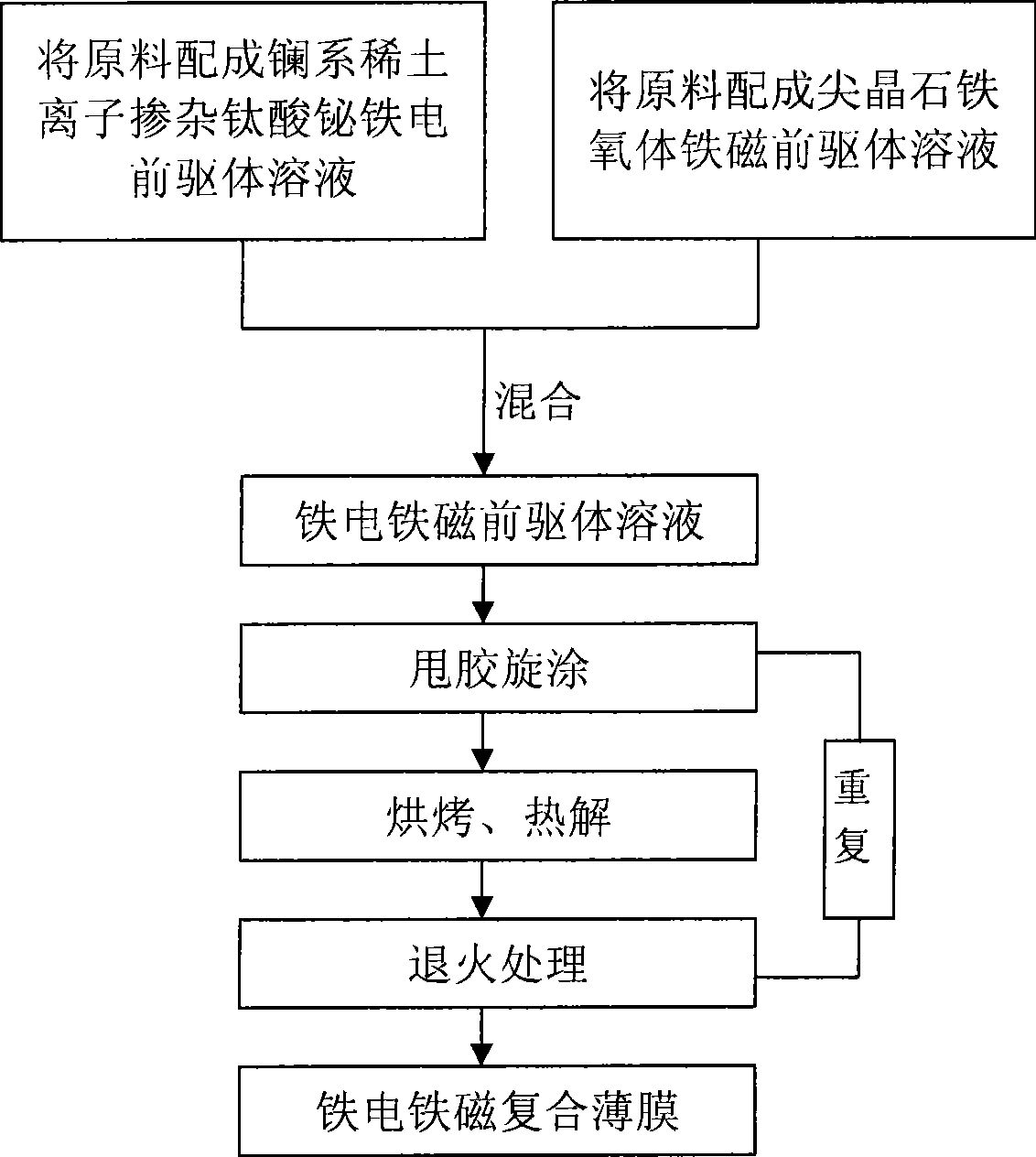

La rear earth ion doped-bismuth titanate spinel ferrite ferroelectric ferromagnetic composite film preparation method

A spinel ferrite, ion doping technology, applied in the application of magnetic film to substrate, magnetic layer, etc., can solve the problem of difficult to achieve molecular level contact, uneven distribution of ferroelectric phase and ferromagnetic phase, etc. problems, to achieve the effect of cheap instruments and raw materials, good microscopic contact, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

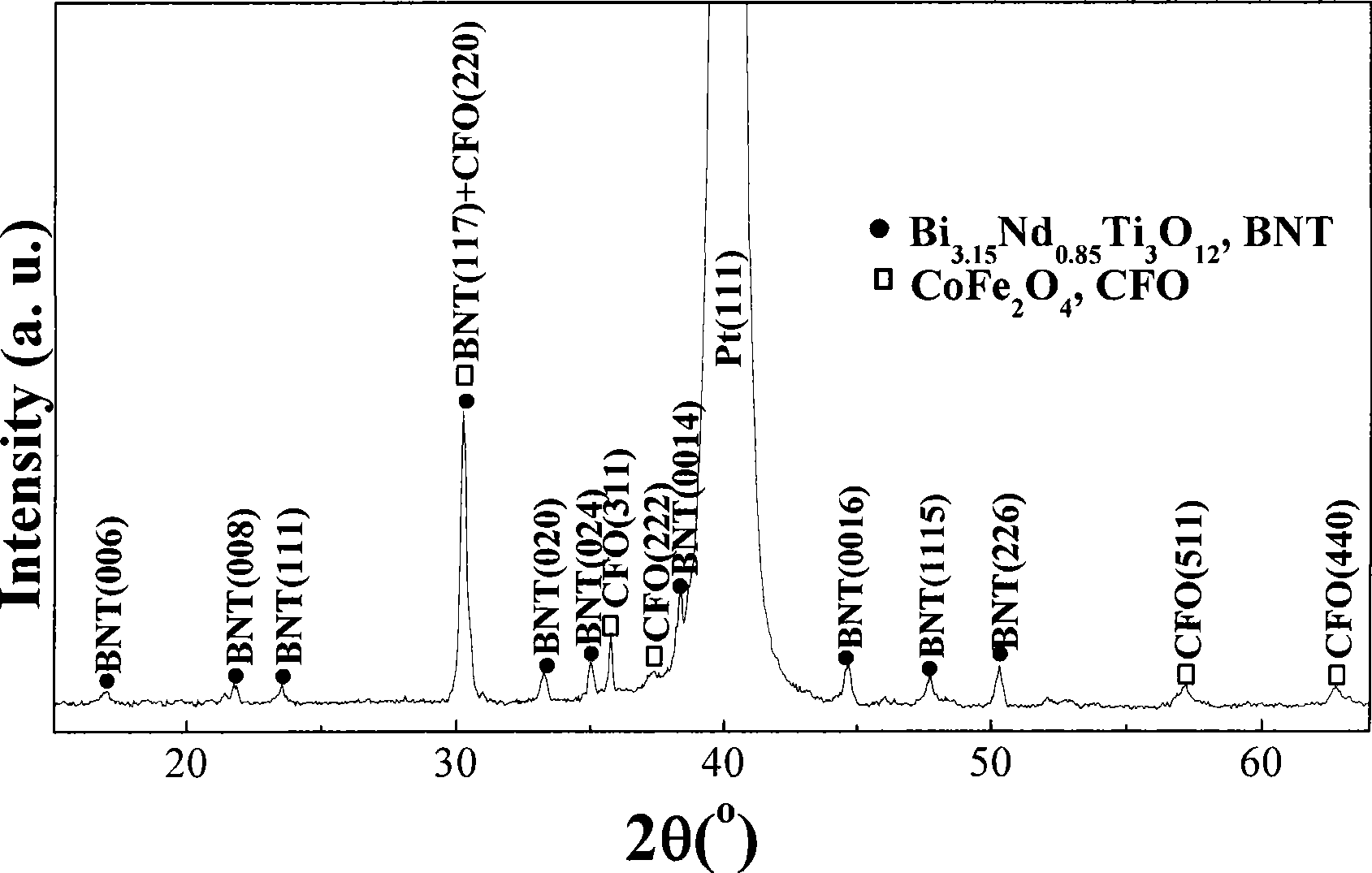

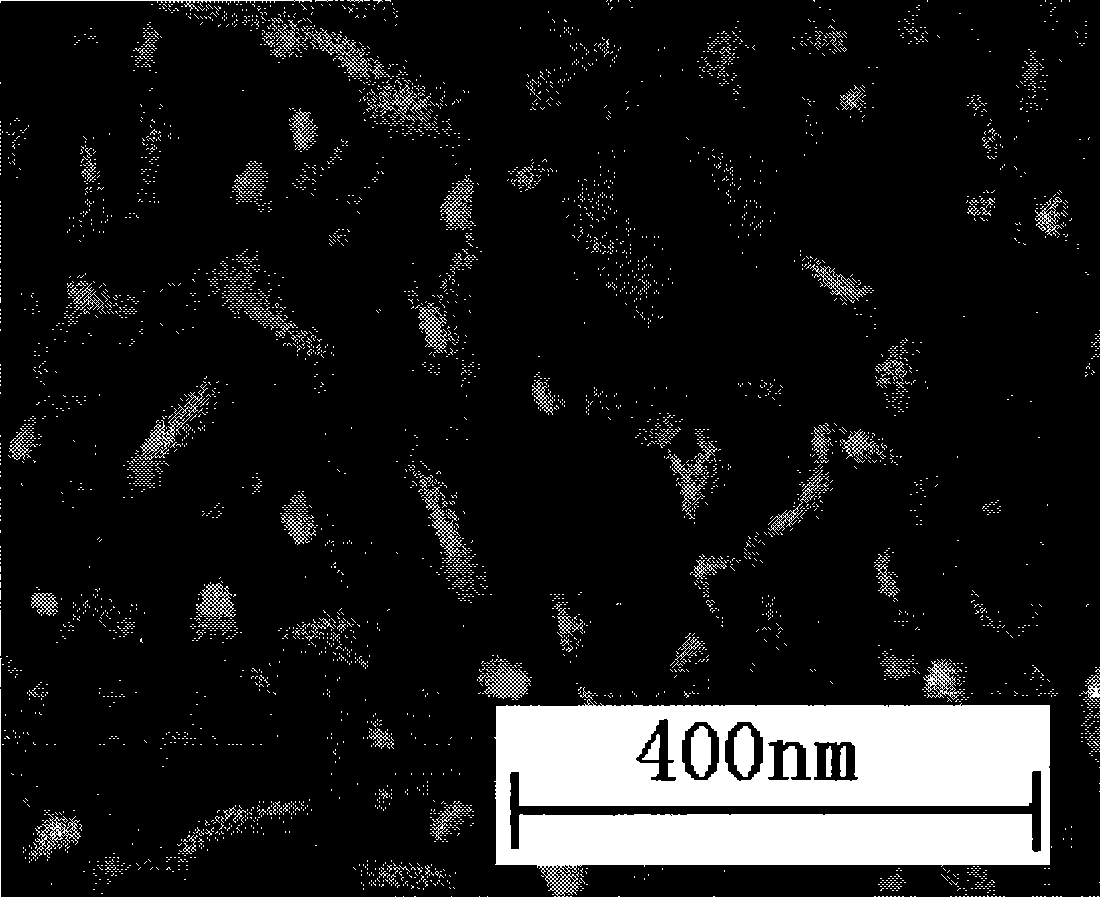

[0032] This experiment is to prepare a composite film with a molar ratio of Nd-doped bismuth titanate and cobalt ferrite at a ratio of 1:1. The specific steps are as follows:

[0033] 1. Preparation of neodymium-doped bismuth titanate / cobalt ferrite mixed solution: first prepare the neodymium-doped bismuth titanate precursor solution, press Bi 3.15 Nd 0.85 Ti 3 o 12In the formula, the mol ratio of Bi and Nd takes by weighing bismuth nitrate (10% in excess) and neodymium nitrate 1.6978g and 0.3865g respectively, then adds glacial acetic acid as solvent, and its mixture is completely dissolved by magnetic stirring at normal temperature to obtain solution A; The molar ratio of bismuth, neodymium and titanium is 3.15:0.85:3, weigh 1.0419g of tetrabutyl titanate and put it into another container, then add an appropriate amount of acetylacetone as a stabilizer, then add the solvent glacial acetic acid, stir for a while to obtain solution B ; While stirring solution A with a magne...

Embodiment 2

[0037] This experiment is to prepare a composite film with a molar ratio of Nd-doped bismuth titanate and cobalt ferrite of 1:0.5. The specific steps are as follows:

[0038] 1. Preparation of neodymium-doped bismuth titanate / cobalt ferrite mixed solution: first prepare the neodymium-doped bismuth titanate precursor solution, press Bi 3。15 Nd 0.85 Ti 3 o 12 In the formula, the mol ratio of Bi and Nd takes by weighing bismuth nitrate (10% in excess) and neodymium nitrate 1.6978g and 0.3865g respectively, then adds glacial acetic acid as solvent, and its mixture is completely dissolved by magnetic stirring at normal temperature to obtain solution A; The molar ratio of bismuth, neodymium and titanium is 3.15:0.85:3, weigh 1.0419g of tetrabutyl titanate and put it into another container, then add an appropriate amount of acetylacetone as a stabilizer, then add the solvent glacial acetic acid, stir for a while to obtain solution B ;While stirring solution A with a magnetic stirr...

Embodiment 3

[0042] This experiment is to prepare a composite film with a molar ratio of Nd-doped bismuth titanate and nickel ferrite of 1:0.75. The specific steps are as follows:

[0043] 1. Preparation of neodymium-doped bismuth titanate / nickel ferrite mixed solution: first prepare the neodymium-doped bismuth titanate precursor solution, press Bi 3.15 Nd 0.85 Ti 3 o 12 In the formula, the mol ratio of Bi and Nd takes by weighing bismuth nitrate (10% in excess) and neodymium nitrate 1.6978g and 0.3865g respectively, then adds glacial acetic acid as solvent, and its mixture is completely dissolved by magnetic stirring at normal temperature to obtain solution A; The molar ratio of bismuth, neodymium and titanium is 3.15:0.85:3, weigh 1.0419g of tetrabutyl titanate and put it into another container, then add an appropriate amount of acetylacetone as a stabilizer, then add the solvent glacial acetic acid, stir for a while to obtain solution B ;While stirring solution A with a magnetic stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com