Optical method and system for monitoring in-situ stress in use for epitaxial growth

A technology of epitaxial growth and in-situ stress, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as large noise and affecting the accuracy of stress monitoring, and achieve simplified image processing, improved precision, and elimination of system effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

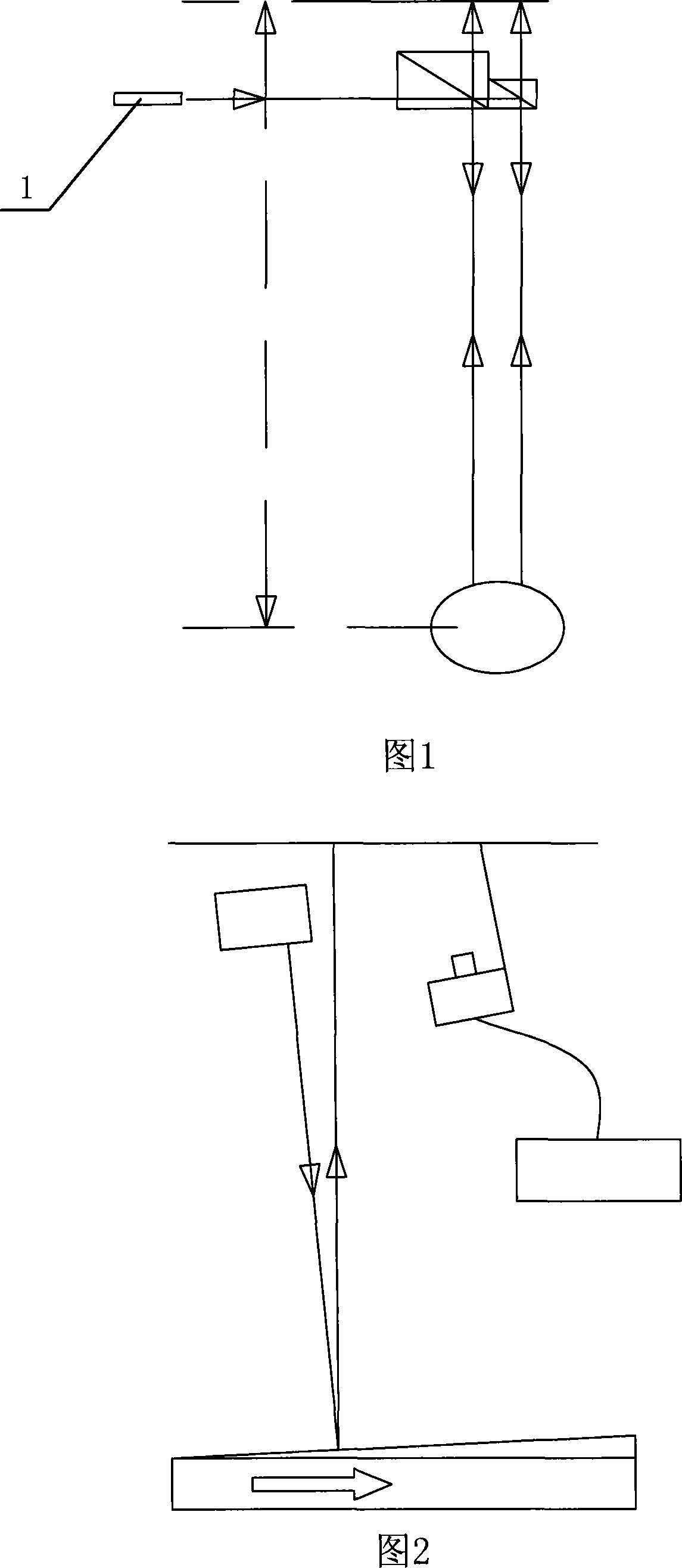

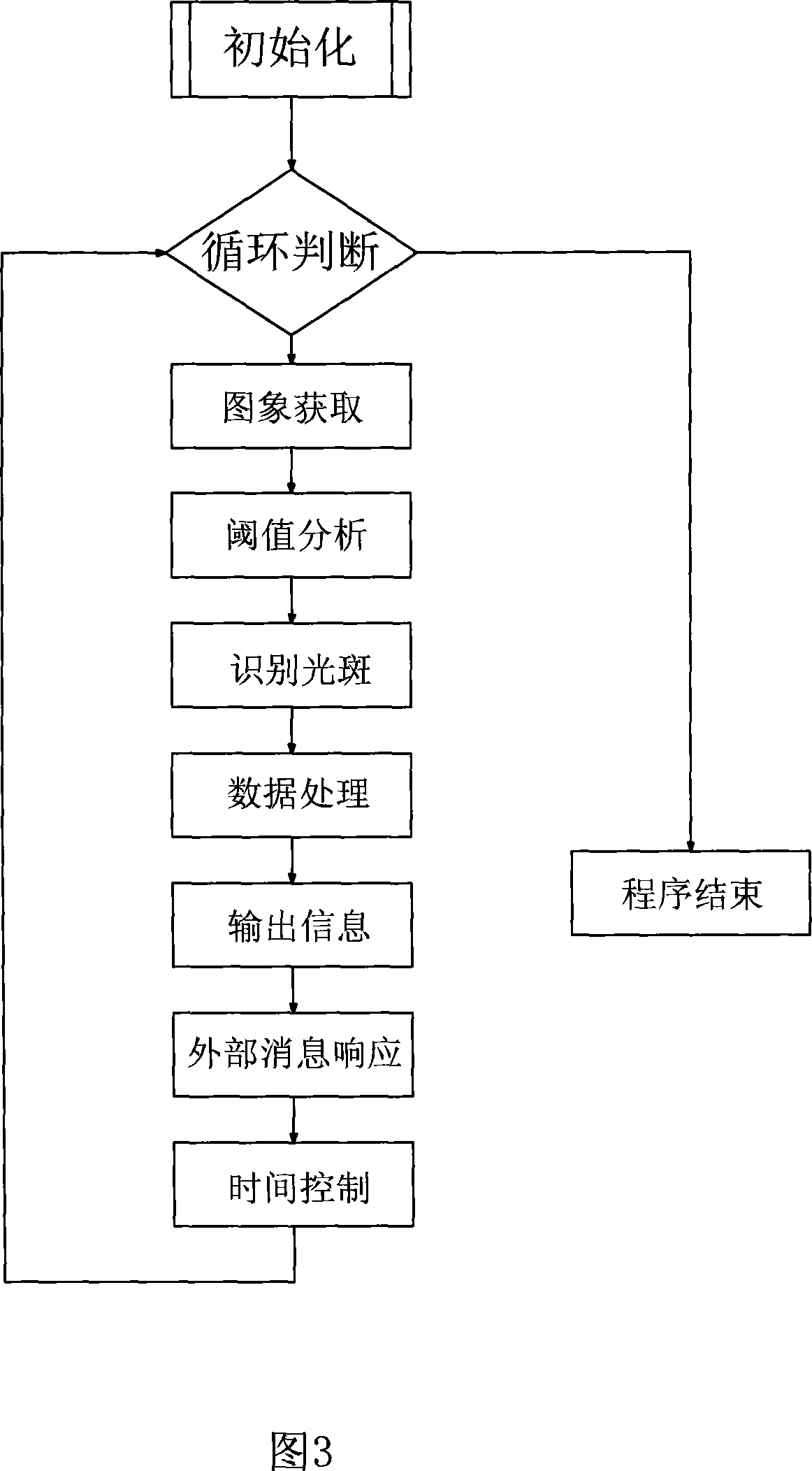

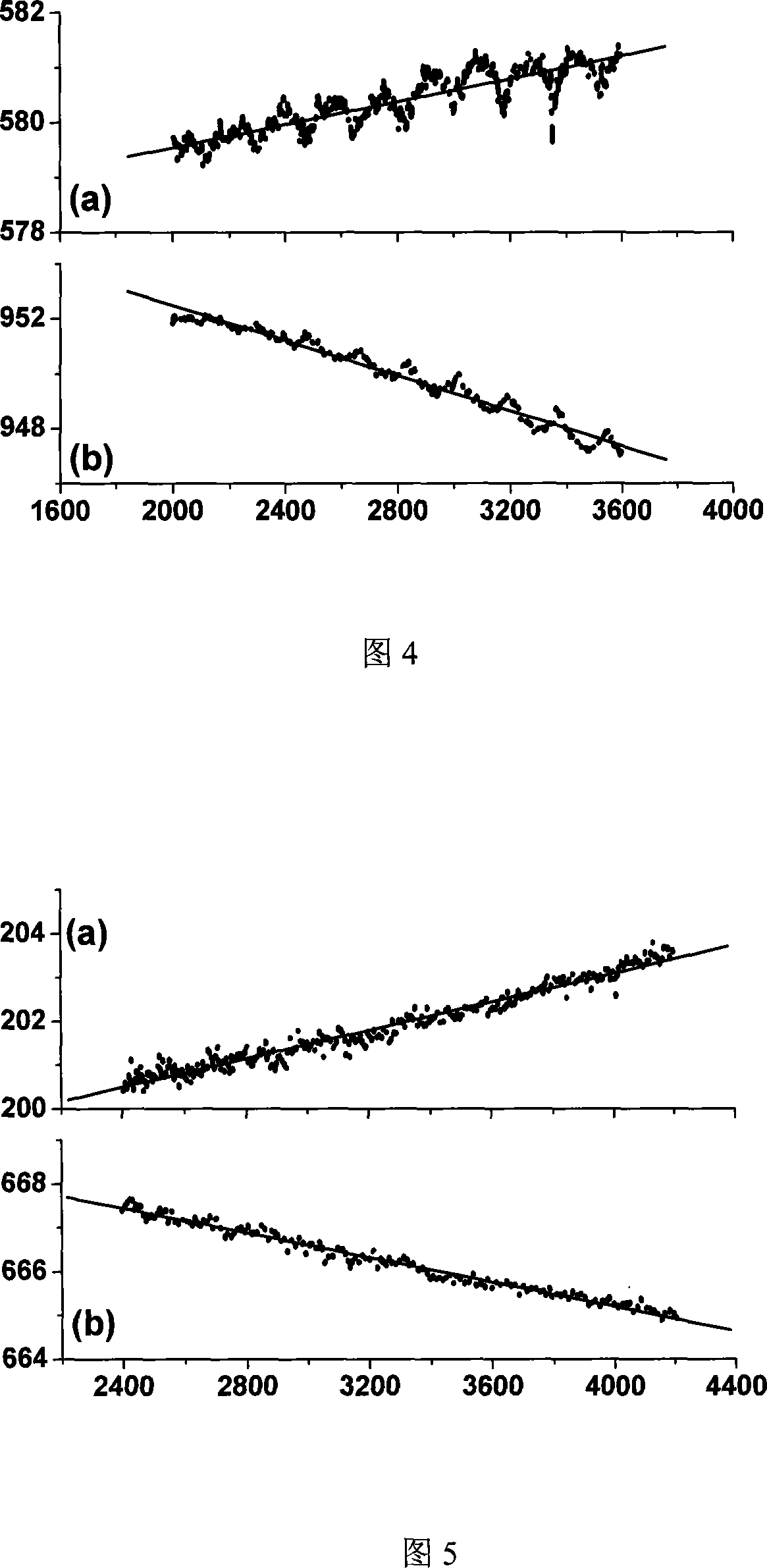

[0036] Embodiment 1: Referring to accompanying drawings 1 to 7, an in-situ stress optical monitoring system for epitaxial growth includes a laser 1, a laser beam splitter, an image acquisition device, a control system, and an optical system constituting a corresponding optical path. component, wherein the optical path is that the laser beam emitted by the laser is split into parallel laser beams by a laser beam splitter, and is incident on the surface of the epitaxial growth sheet to be tested through an optical element, and the reflected light is emitted through an optical element, forming an image On the image acquisition device, the wavelength of the laser is smaller than the wavelength corresponding to the bandwidth of the epitaxial growth sheet material to be tested. The image acquisition device is mainly composed of a projection board and a camera. In the optical path, the outgoing light is imaged on the projection board, and the light spot on the projection board is imag...

Embodiment 2

[0039] Embodiment 2: Referring to accompanying drawings 6 and 7, an in-situ stress optical monitoring system for epitaxial growth includes a laser 1, a laser beam splitter, an image acquisition device, a control system, and an optical system constituting a corresponding optical path. component, wherein the optical path is that the laser beam emitted by the laser is split into parallel laser beams by a laser beam splitter, and is incident on the surface of the epitaxial growth sheet to be tested through an optical element, and the reflected light is emitted through an optical element, forming an image On the image acquisition device, the wavelength of the laser is smaller than the wavelength corresponding to the bandwidth of the epitaxial growth sheet material to be tested, and the control system is composed of a computer 2 and control software.

[0040] When applied to halide vapor phase epitaxy (HVPE) equipment, its structural diagram is shown in Figure 6, wherein, the sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com