Novel hollow fiber film separating device and its preparation method

A technology for separators and fiber membranes, applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of reduced membrane separation performance, affecting membrane separation performance, and restricting hollow fiber gas separation membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

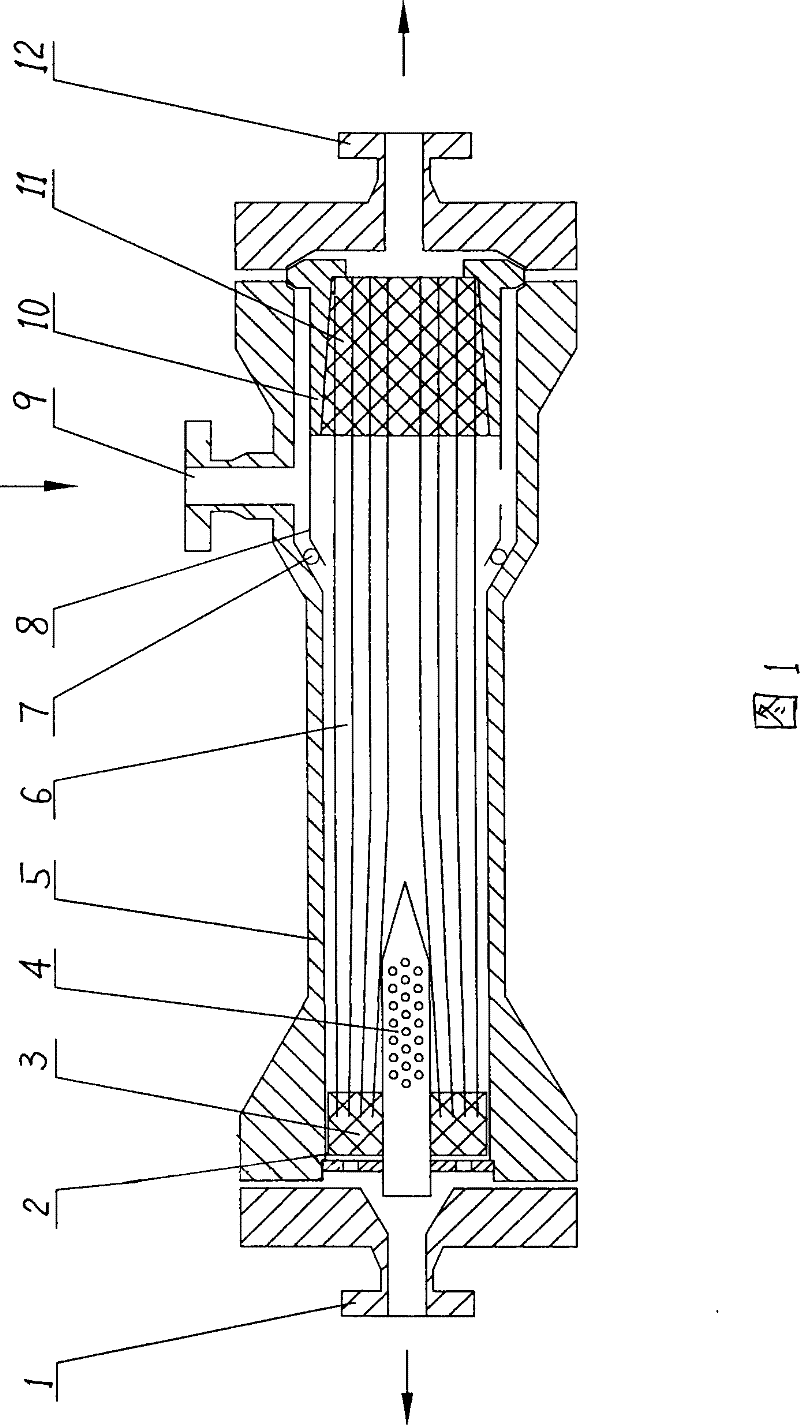

[0030] Such as figure 1 In the novel hollow fiber membrane separator shown, tens of thousands or hundreds of thousands of hollow fiber gas separation membranes are made into fiber bundles 6 and then installed in a pressure-resistant steel casing 5, and one end of the fiber bundles is bonded with a resin adhesive It is casted into a resin head 11 and fixed at one end of the separator through a fixing jacket 10. The other end of the fixing jacket 10 and the outer shell are sealed with an O-ring 7, and some raw materials are distributed on the outer surface of the fixing jacket. Gas guide holes 8, so that raw gas can enter the shell side of the membrane separator, and the inner cavity of the hollow fiber gas separation membrane communicates with the outside to form a permeable gas channel 12. The tail end of the fiber bundle is sealed with resin to form a plug 3, which is fixed at the other end of the separator. At the end of the plug 3, the gap between the hollow fiber gas separ...

Embodiment 2

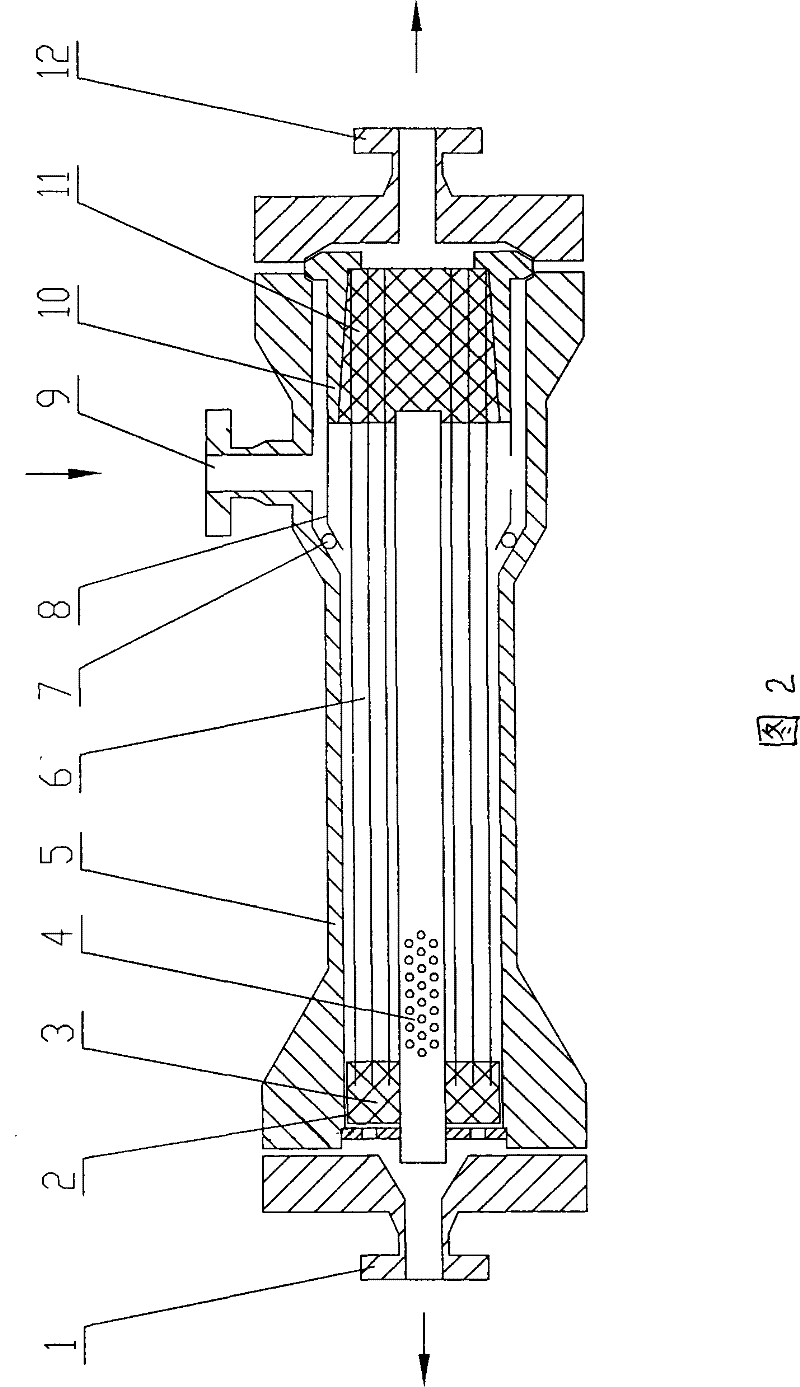

[0033] Such as figure 2 As shown, the basic structure is the same as that of Example 1, except that the tail gas collection pipe 4 at the tail end of the fiber bundle 6 is extended to the inside of the fiber bundle resin head 11, and the airflow mode in the separator is the same as that of Example 1. The exhaust gas collection pipe in the device also supports the fiber bundle.

Embodiment 3

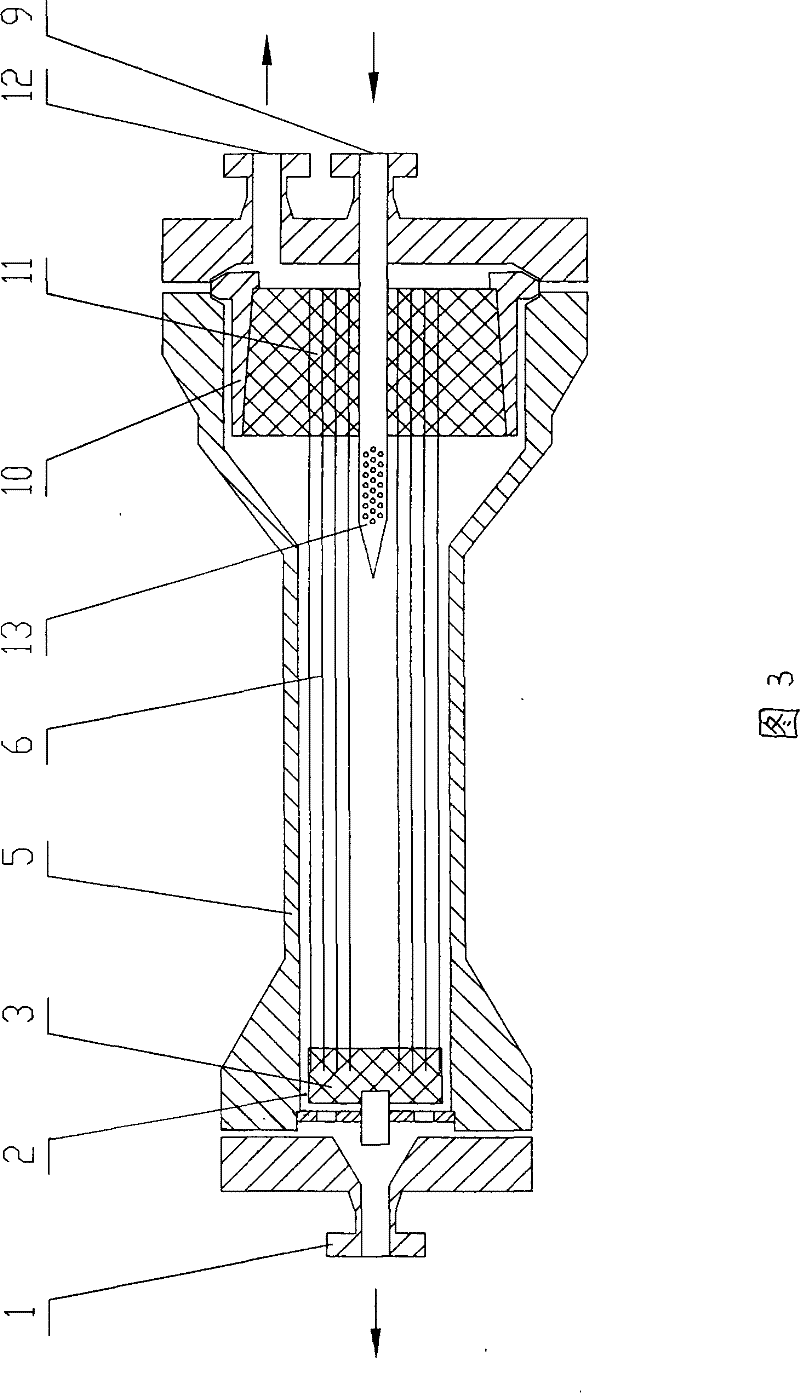

[0035] Such as image 3 As shown, the hollow fiber gas separation membrane is made into a fiber bundle 6 and then installed in a pressure-resistant steel casing 5. The exhaust gas discharge channel is the annulus 2 between the plug at the end of the fiber bundle and the casing. One end of the fiber bundle is used The resin adhesive is cast into a resin head 11, which is fixed at one end of the separator through a fixing jacket 10, and a center pipe is installed in the center of the resin head as a raw material gas distribution pipe 13 to form a raw material gas distribution pipe. The resin head 11, the position of the feed gas inlet 9 is changed directly above the resin head, connected with the feed gas distribution pipe 13, and opening holes on the surface of the feed gas distribution pipe to form the passage for the feed gas to enter the membrane separator. The opening area is usually between 0-500cm below the resin head 11, preferably between 20-200cm. The feed gas is fed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com