Core-shell structure composite nanometer material and preparation method thereof

A technology of composite nanomaterials and core-shell structure, which is applied in the field of composite nanomaterials with dielectric metal core-shell structure and its preparation, can solve the problems of expensive and restricting the popularization and application of nanomaterials, and achieve simple steps, good economic benefits and promotion value , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Prepare SiO by Stber method 2 Nanoparticles, 20mL of water and 50mL of absolute ethanol as a solvent, mixed with 5mL of ethyl orthosilicate evenly under the action of magnetic stirring, then added about 10mL of ammonia water drop by drop, a few minutes after the reaction started, milky white gradually appeared in the solution, indicating that SiO 2 Nanoparticles began to form. After stirring for 12 hours and reflux for 1 hour, the mixed solution was centrifuged and washed 4-5 times under the condition of 6000 r / m to fully remove the remaining reactants. The BT-2003 laser particle size distribution analyzer was used to measure the SiO 2 The particle size of the nanoparticles is 200nm. Finally SiO 2 Nanoparticles were dispersed in 20 mL of absolute ethanol to make SiO 2 Sol spare.

[0026] (2) Soak the quartz plate in a mixture of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 7:3 for 3 hours, then ultrasonically clean it with high-purity ...

Embodiment 2

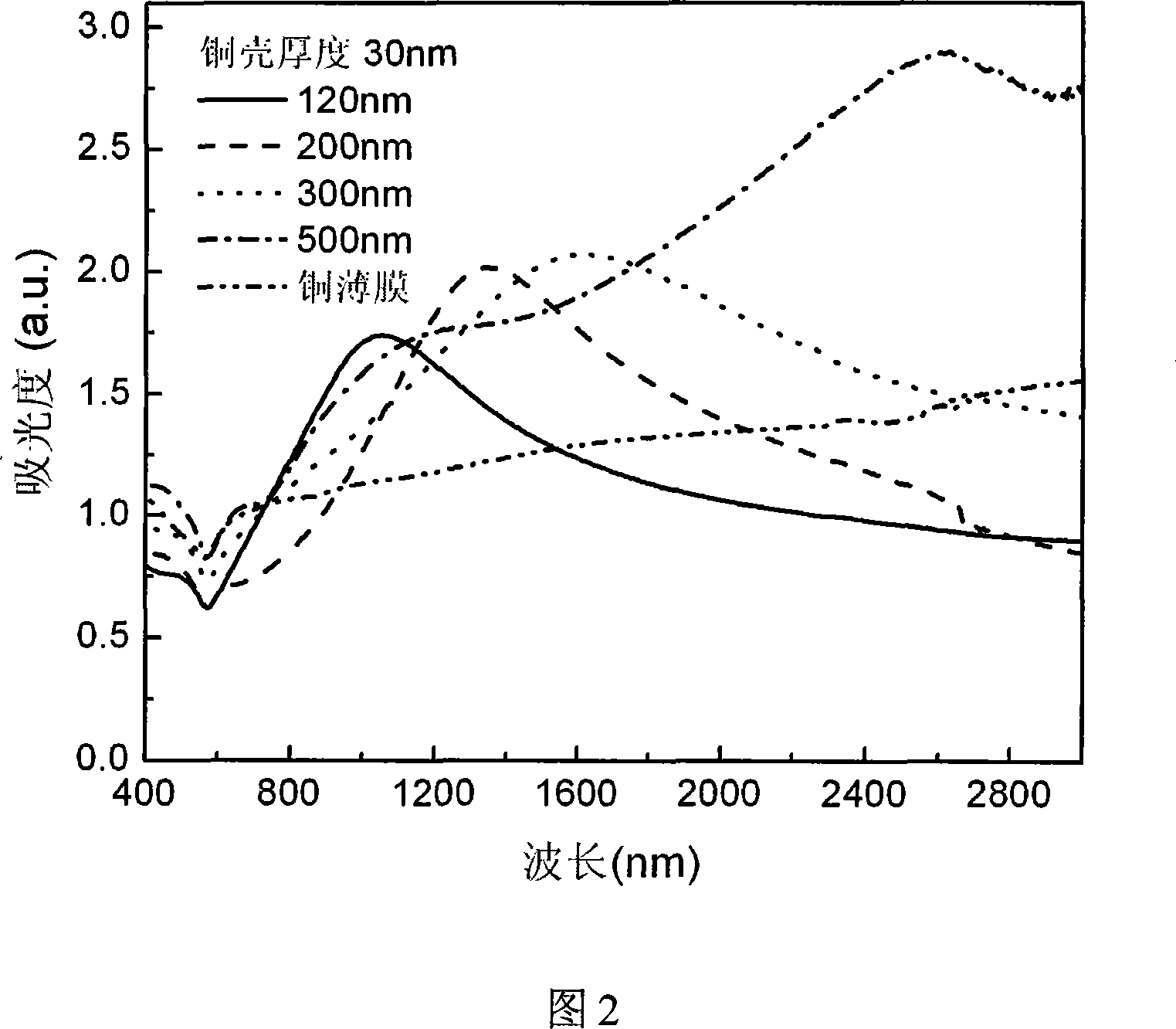

[0030] (1) Prepare SiO by Stber method 2 Nanoparticles, 20mL of water and 50mL of absolute ethanol as a solvent were mixed with 3, 5, 8, and 15mL of ethyl orthosilicate under the action of magnetic stirring, and then about 10mL of ammonia water was added drop by drop. After continuous stirring for 12 hours and reflux for 1 hour, the The mixed solution was centrifuged and washed 4-5 times under the condition of 6000r / min to fully remove the remaining reactants, and the BT-2003 laser particle size distribution analyzer was used to measure SiO 2 The diameters of the nanoparticles are about 120, 200, 300, 500 nm, respectively. Finally SiO 2 Nanoparticles were dispersed in 20 mL of absolute ethanol to make SiO 2 Sol spare.

[0031] (2) Soak the quartz plate in a mixture of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 6:4 for 2 hours, then ultrasonically clean it with high-purity water and absolute ethanol, and then bake it in a drying oven at 110°C fo...

Embodiment 3

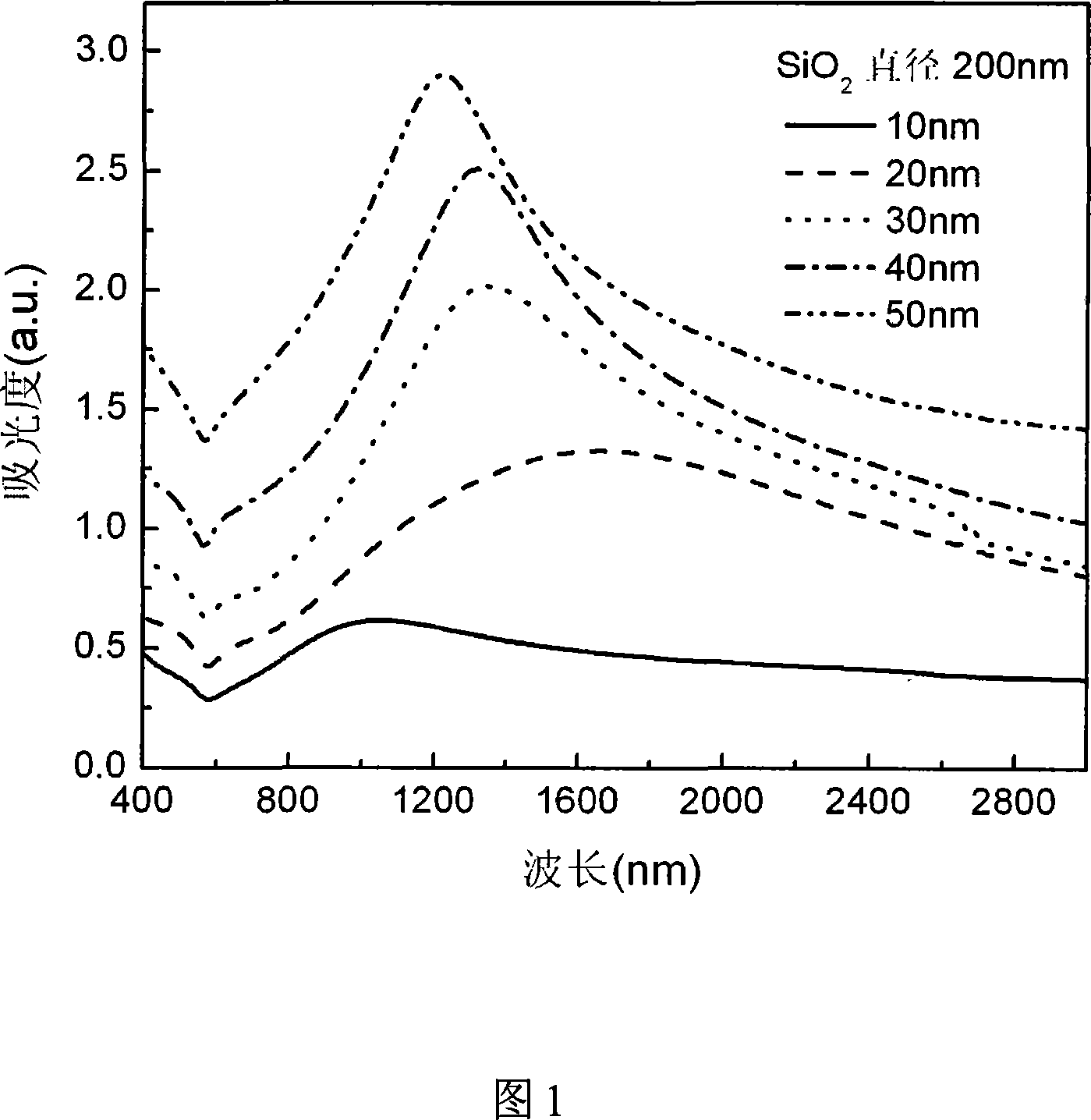

[0035] (1) Prepare SiO by Stber method 2 Nanoparticles, 20mL of water and 50mL of absolute ethanol were mixed with 5mL of ethyl orthosilicate evenly under the action of magnetic stirring, and then 10mL of ammonia water was added drop by drop, and after continuous stirring for 12h and reflux for 1h, the mixed solution was mixed under the condition of 6000r / min Centrifuge and wash 4-5 times to fully remove the remaining reactants, and use BT-2003 laser particle size distribution analyzer to measure SiO 2 The particle size of the nanoparticles is 200nm. Finally SiO 2Nanoparticles were dispersed in 20 mL of absolute ethanol to make SiO 2 Sol spare.

[0036] (2) Soak the quartz plate in a mixture of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 8:2 for 4 hours, then ultrasonically clean it with high-purity water and absolute ethanol, and then bake it in a drying oven at 130°C for 1 hour. Put the quartz slice on the KW-4A desktop glue homogenizer, drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com