Method for producing Chinese red pine chemical pulp

A technology of chemical pulp and production method, applied in papermaking, textiles and papermaking, pulping with inorganic alkali, etc., can solve the problems of high energy consumption, low pulp quality, large production scale, etc., and achieve low energy consumption, Excellent slurry quality and stable kappa value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

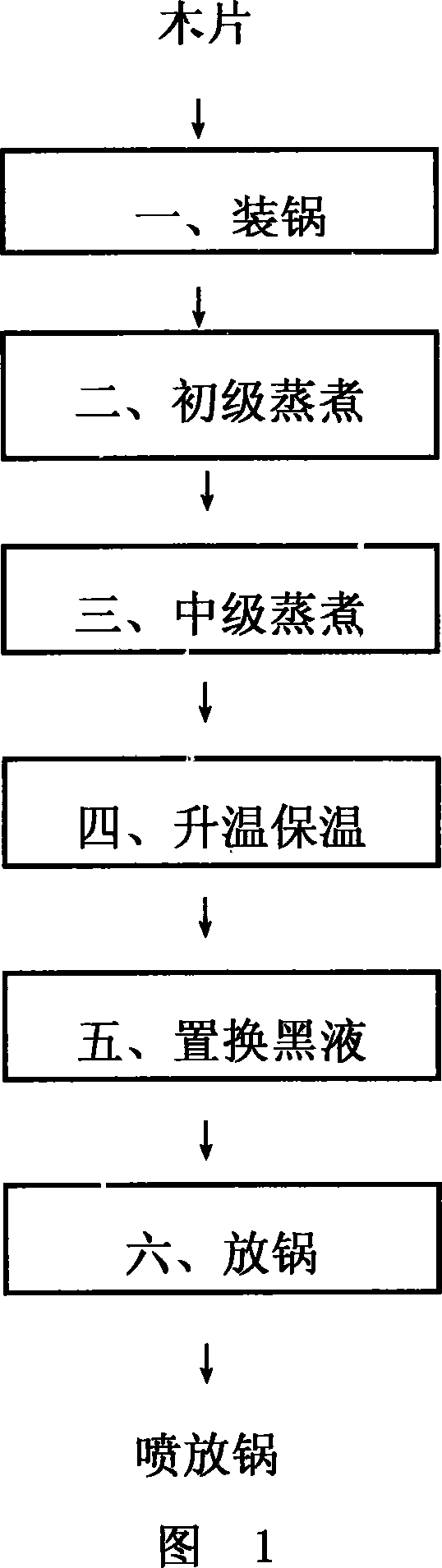

[0025] The production method of embodiment one is as follows:

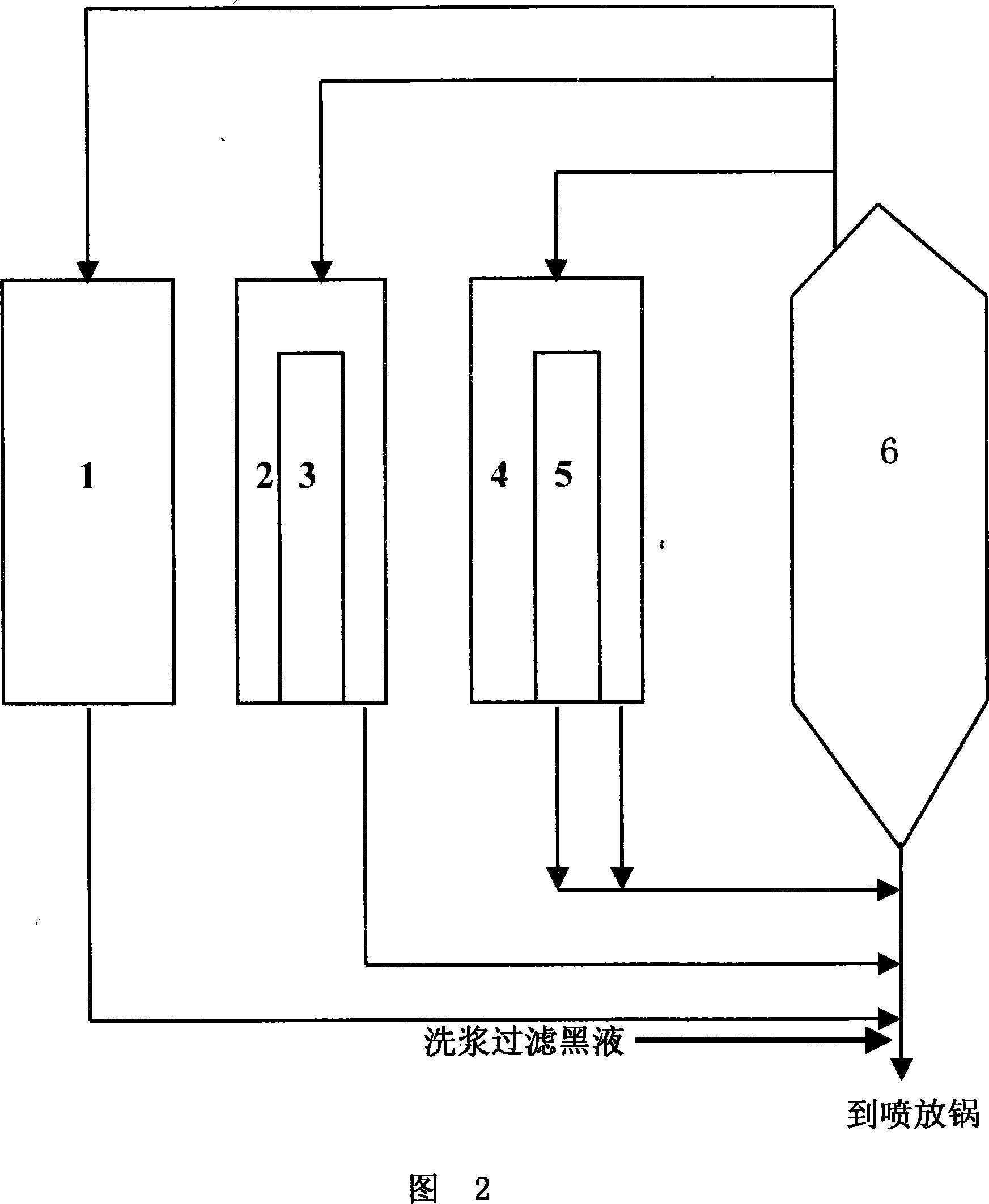

[0026] Step 1, pot loading: 100% masson pine wood chips are put into the cooking pot 6, and the black liquor is fed into the cold black liquor tank 1 while loading the wood chips, and the pot cover valve is covered after being installed.

[0027] Step 2, primary cooking: Put the wood chips after step 1 in a sealed cooking pot, using a liquid ratio of 1:8.1 (the amount of warm cooking liquid per ton of dry wood chips is 8.1M 3 ) of the warm cooking liquor, replace the black liquor when filling the pot, and distribute to different black liquor tanks according to different temperature sections, the amount of alkali used in the warm cooking liquor is 6% of the absolute dry raw material (calculated by effective alkali and sodium oxide), The degree of sulfidation of the lye is 24%; the temperature of the warm cooking liquid is 140°C, and the black liquor at the time of filling the pot is replaced, and the black liquor b...

Embodiment 2

[0033] The production method of embodiment two is as follows:

[0034] Step 1, pot loading: 90% masson pine and 10% hardwood chips are packed into the cooking pot 6, and the black liquor is fed into the black liquor while loading the chips in the cold black liquor tank 1, and the lid valve of the pot is covered after being installed.

[0035] Step 2, primary cooking: the wood chips after step 1 are placed in a sealed cooking pot, and the liquid ratio is 1: 7.9 (the amount of warm cooking liquid per ton of dry wood chips is 7.9M 3 ) warm cooking liquid to replace the black liquor when it was loaded into the pot, and distribute it to different black liquor tanks according to different temperature sections. The degree of sulfidation of the liquid is 15%; the temperature of the warm cooking liquid is 135°C, and the black liquor in the pot is replaced, and the black liquor tank 1 below 95°C is used for the potting of the next pot and the recovery of alkali delivery; The 95°C black...

Embodiment 3

[0041] The production method of embodiment three is as follows:

[0042] Step 1, pot loading: 70% masson pine wood chips and 30% broad-leaved wood chips are packed into the cooking pot 6, and the black liquid is filled with the cold black liquor tank 1 while the black liquor is loaded and the lid valve is covered.

[0043] Step 2, primary cooking: put the wood chips after step 1 in a sealed cooking pot, and the liquid ratio is 1: 8.4 (the amount of warm cooking liquid per ton of dry wood chips is 8.4M 3 ) of the warm cooking liquid to replace the black liquor when it was loaded into the pot, and distribute it to different black liquor tanks according to different temperature sections. The amount of alkali used in the warm cooking liquid is 7% of the dry raw material (calculated by effective alkali and sodium oxide), The sulfidation degree of the liquid is 30%; the temperature of the warm cooking liquid is 145°C, and the black liquor when it is loaded into the pot is replaced, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com