Thin film structure for reducing laser direct writing photo-etching point or line width and its preparation method

A thin-film structure and laser direct writing technology, which is applied in laser welding equipment, microlithography exposure equipment, optomechanical equipment, etc., can solve problems such as complex process, high cost, and difficult industrialization direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

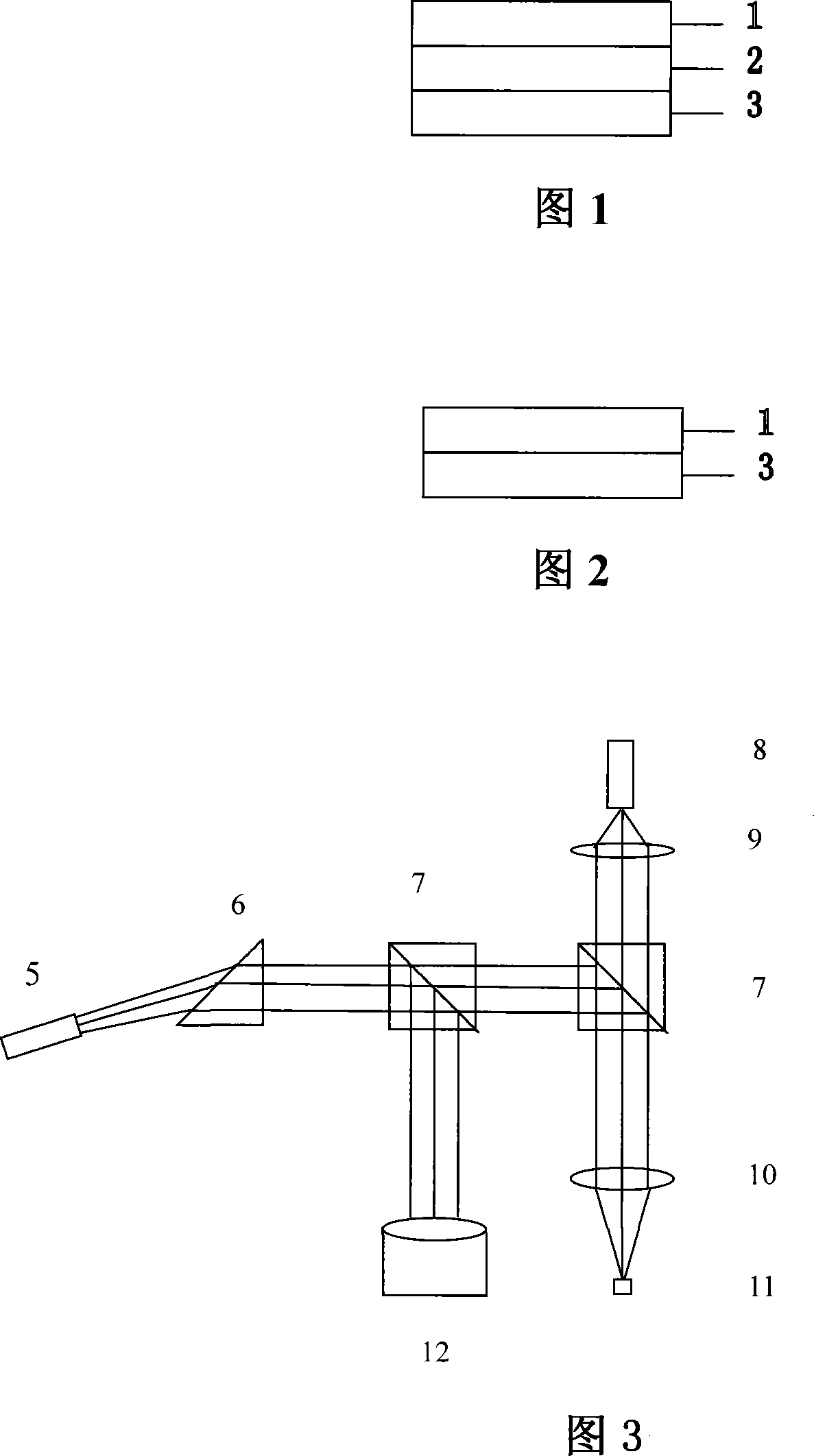

[0019] The preparation method of the thin film structure reducing laser direct writing lithography point or line width is characterized in that it comprises the following steps:

[0020] ①Put the glass substrate 3 into absolute alcohol, and clean it two to three times with an ultrasonic generator, 10 minutes each time;

[0021] ②Put the cleaned glass substrate into the sputtering chamber of the high-vacuum magnetron sputtering equipment after drying, and vacuumize. When the background vacuum in the sputtering chamber drops to 6.0*10 -4 At Pa, argon is passed through, and the argon pressure is maintained at 0.6-1.0Pa;

[0022] ③ preparing the buffer layer 2 on the glass substrate 3 by DC magnetron sputtering;

[0023] ④ Prepare the inorganic phase change thin film layer 1 on the buffer layer 2 by DC magnetron sputtering method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com