Method for preparing all vanadium ion redox flow battery electrolyte

A liquid flow battery and electrolyte technology, which is applied in chemical instruments and methods, fuel cell parts, secondary batteries, etc., can solve the problems of increasing the electrolyte concentration and stability of vanadium batteries, and achieve good electrochemical reversibility , good stability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

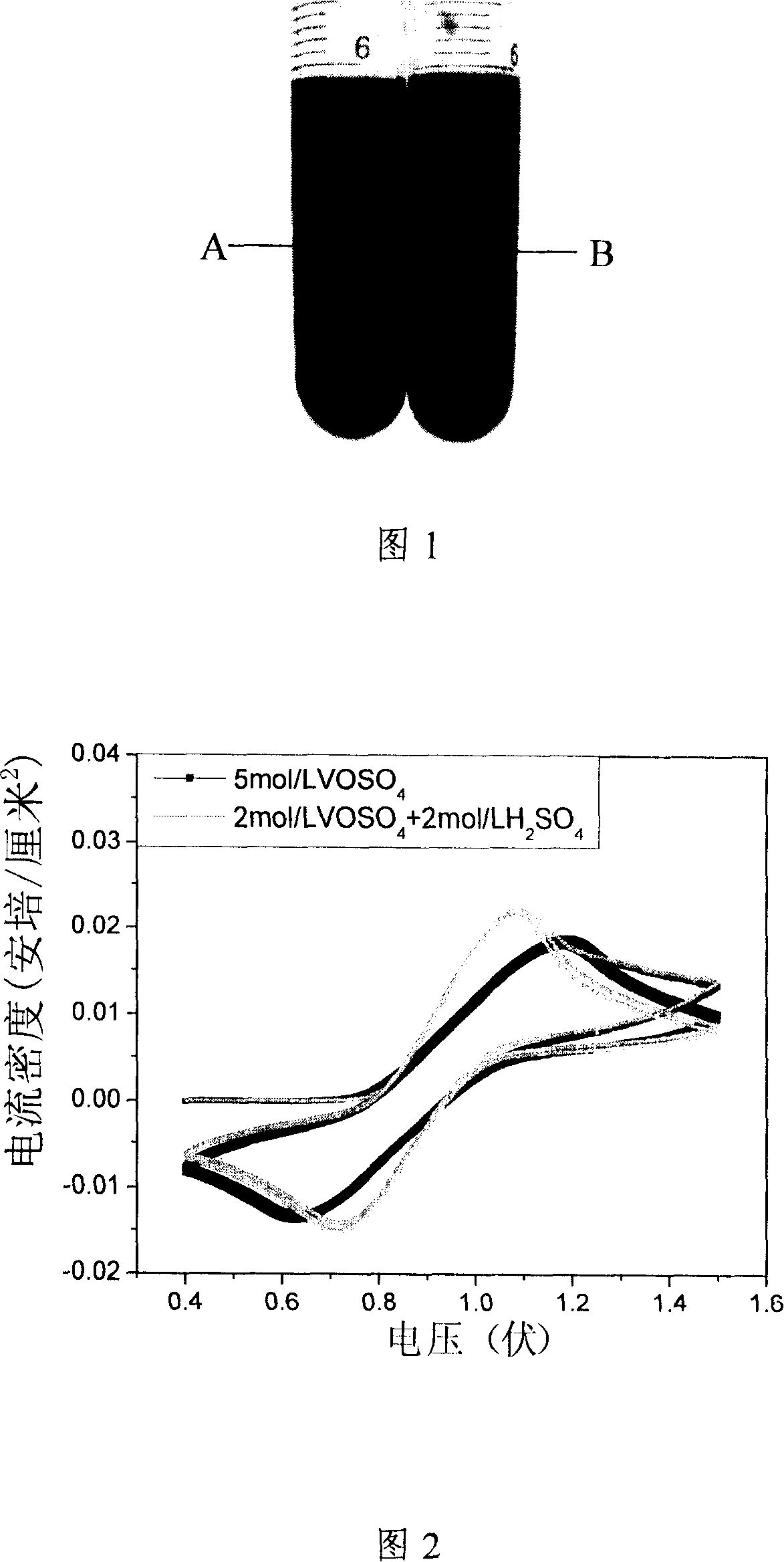

Embodiment 1

[0023] 0.02mol ethylenediamine, 0.02mol pyridine, 0.02mol thiazole, 0.2mol KNO 3 , 0.2mol NaNO 3 , 0.02mol EDTA, 1.5mol sulfuric acid were dissolved in 2L deionized water to prepare a composite stabilizer solution. Then weigh 5 mol of vanadyl sulfate, dissolve and dilute it to 1000 mL with a composite stabilizer solution to obtain a 5 mol / L vanadyl sulfate solution. Graphite is used as the positive and negative electrode materials, the concentrations of the positive and negative electrode solutions are 5mol / L vanadyl sulfate and 3mol / L vanadyl sulfate solution, and the charging current density is 11.5mA / cm 2 , the discharge current density is 4mA / cm 2 , the initial discharge voltage is 1.96V, the average discharge voltage is 1.24V, the voltage efficiency is 60%, and the energy efficiency is 75%.

Embodiment 2

[0025] With 0.02mol diethylenetriamine, 0.02mol imidazole, 0.02mol 2-(2,4-diylphenylthio)benzothiazole, 0.2mol LiNO 3 , 0.4mol MgCl 2 , 0.2mol EGTA, 1.5mol sulfuric acid were dissolved in 2L deionized water to prepare a composite stabilizer solution. Then weigh 5 mol of vanadyl sulfate, dissolve and dilute it to 1000 mL with a composite stabilizer solution to obtain a 5 mol / L vanadyl sulfate solution. Graphite is used as the positive and negative electrode materials, the concentrations of the positive and negative electrode solutions are 5mol / L vanadyl sulfate and 3mol / L vanadyl sulfate solution, and the charging current density is 11.5mA / cm 2 , the discharge current density is 4mA / cm 2 , the initial discharge voltage is 1.92V, the average discharge voltage is 1.22V, the voltage efficiency is 60%, and the energy efficiency is 73%.

Embodiment 3

[0027] Weigh 5 mol of vanadyl sulfate, add 800 mL of deionized water, heat, and after it is initially dissolved, add: 0.01 mol of aniline, 0.01 mol of 1,10-phenanthroline, 0.01 mol of furan, 0.1 mol of CaCl 2 , 0.03molNa 2 SO 4 , 0.01mol EDTA, 1.5mol sulfuric acid, continue to stir, after completely dissolving, set the volume to 1000mL to obtain a 5mol / L vanadyl sulfate solution. Graphite is used as the positive and negative electrode materials, the concentrations of the positive and negative electrode solutions are 5mol / L vanadyl sulfate and 3mol / L vanadyl sulfate solution, and the charging current density is 11.5mA / cm 2 , the discharge current density is 4mA / cm 2 , the initial discharge voltage is 1.90V, the average discharge voltage is 1.22V, the voltage efficiency is 60%, and the energy efficiency is 74%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com