Method for controlling conversion of isotactic polybutylene-1 crystal system two to crystal system one by carbon dioxide

A technology of isotactic polybutene and crystal form, applied in the field of transformation from crystal form II of polybutene-1 to crystal form I, can solve the problems of small processing capacity, high equipment requirements, difficult process control, etc., and achieve the transformation period reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

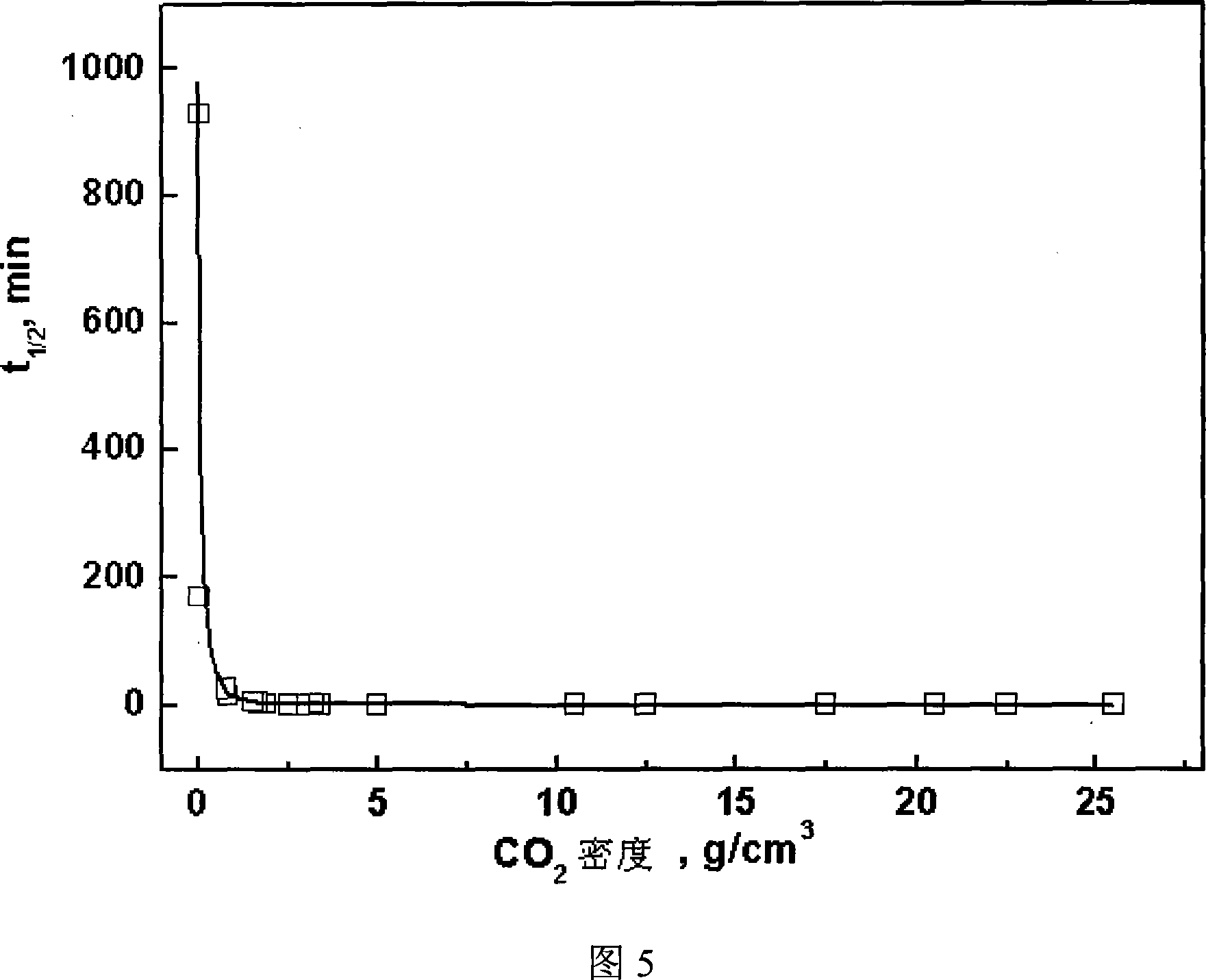

[0021] Place the isotactic polybutene-1 membrane with a thickness of 1mm in the crystal form II in a high-pressure container, and then pass through CO 2 , to control the CO in the high-pressure vessel 2 The temperature is 5°C and the pressure is 30 MPa.

[0022] After the temperature and pressure stabilized, the isotactic polybutene-1 in CO 2 Take out after 0.1 hour of medium treatment.

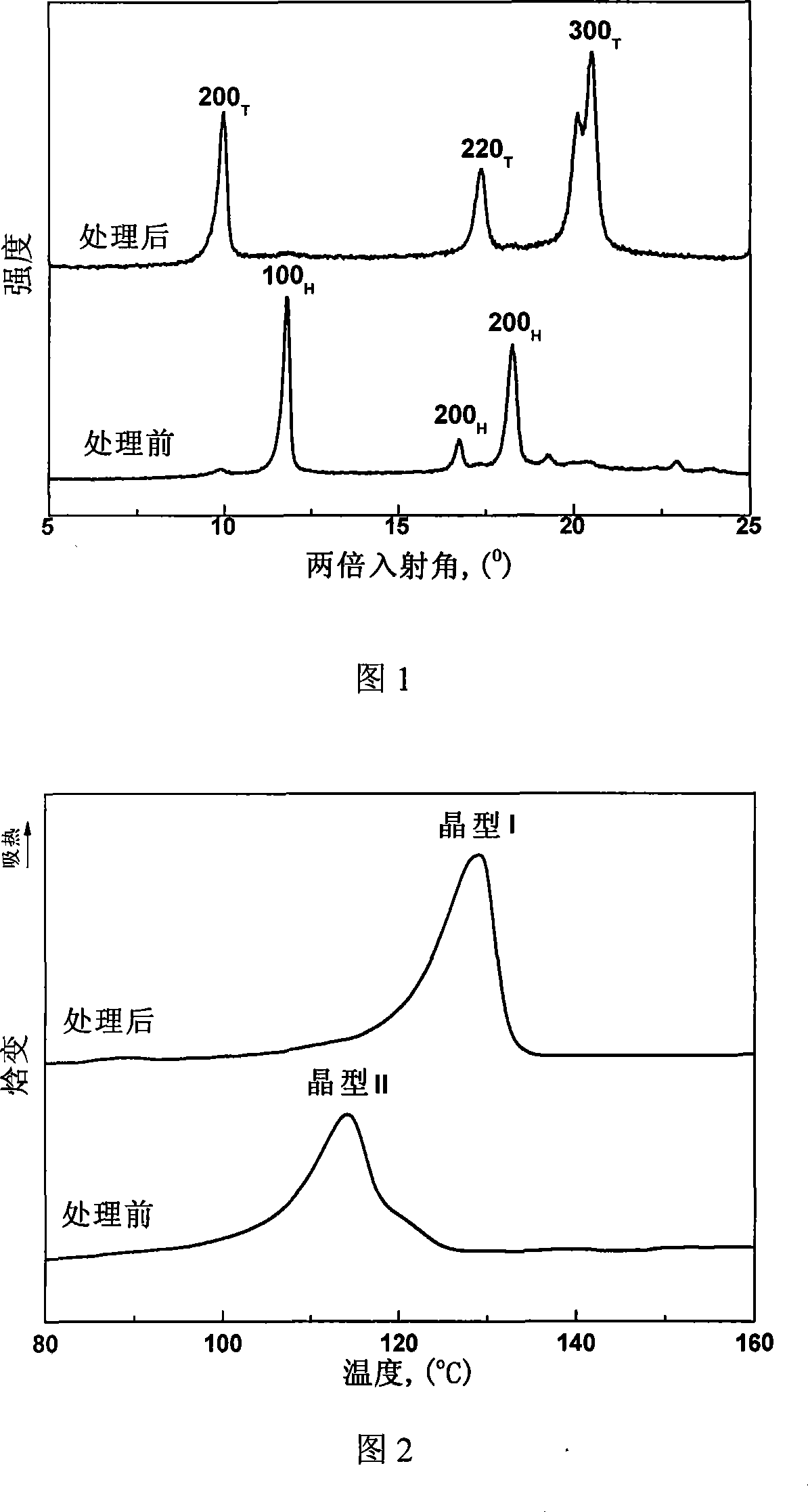

[0023] Through X-ray diffraction analysis (XRD), see Figure 1, it can be drawn from the diffraction pattern that the characteristic diffraction peaks that characterize the crystal form II have all disappeared, indicating that the crystal form II in the treated isotactic polybutene-1 film is All transformed into crystal form I; through differential scanning calorimetry (DSC), see Figure 2, only the melting peak of crystal form I appeared in the DSC curve, and it also showed that crystal form II was completely transformed into crystal form I . That is to say, in CO 2 The density is 28.1152...

Embodiment 2

[0025] Place isotactic polybutene-1 particles with a diameter of 3-5 mm in a high-pressure container, and then pass a certain amount of CO 2 , to control the CO in the high-pressure vessel 2 The temperature is 120° C. and the pressure is 30 MPa.

[0026] After the temperature and pressure stabilized, the isotactic polybutene-1 in CO 2 Take out after 0.15 hours of medium treatment.

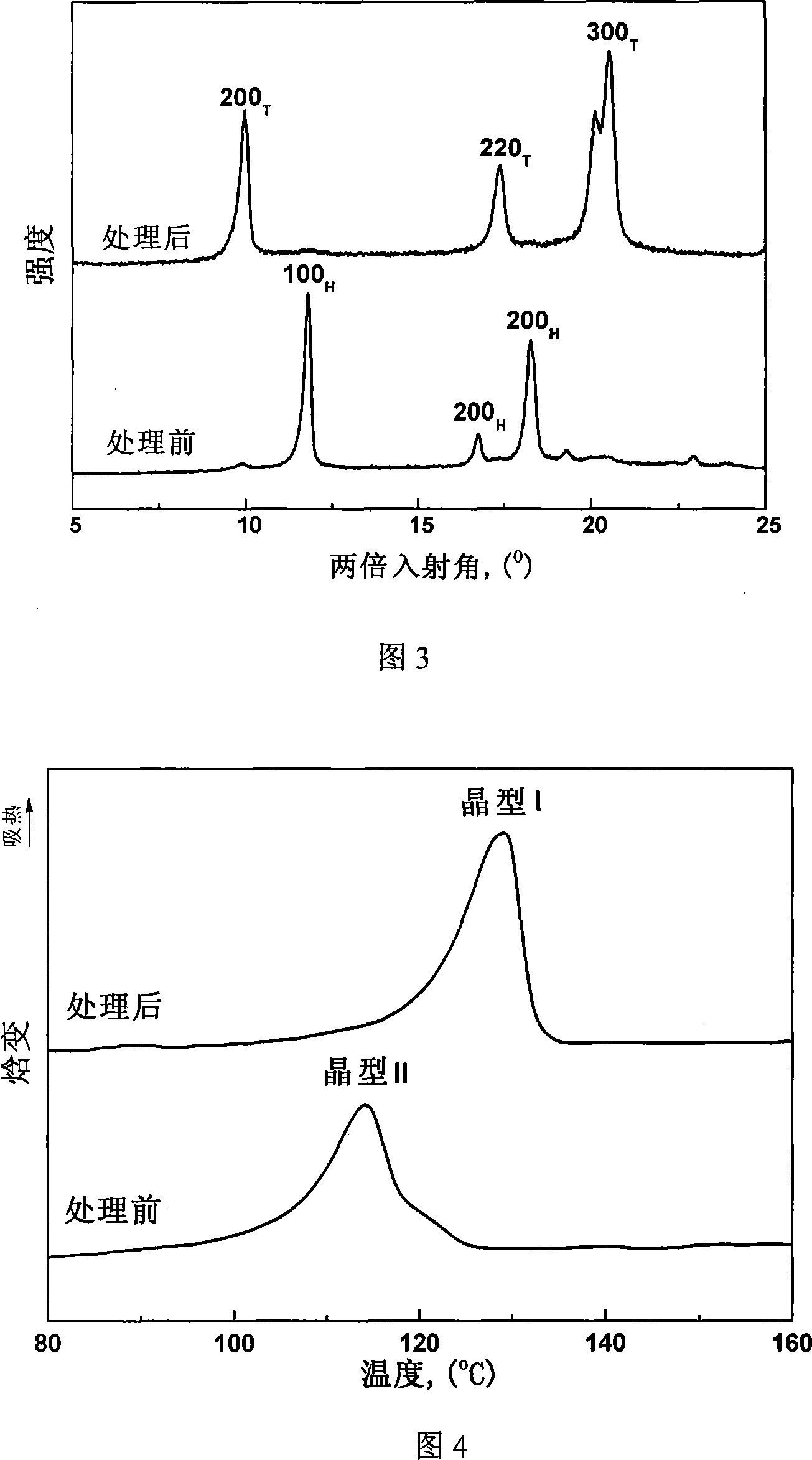

[0027] By X-ray diffraction analysis (XRD), see Figure 3, as can be seen from the diffraction pattern, the characteristic diffraction peaks that characterize the crystal form II have all disappeared, indicating that all of the crystal form II in the isotactic polybutene-1 particles after treatment Transformed into Form I; through differential scanning calorimetry (DSC), see Figure 4, only the melting peak of Form I appears in the DSC curve, and it also shows that Form II is completely transformed into Form I. That is to say, in CO 2 The density is 25.7473g / cm 3 After 0.15 hours, the crystal fo...

Embodiment 3

[0029] Put powdery isotactic polybutene-1 particles in a high-pressure container, and then pass a certain amount of CO 2 , to control the CO in the high-pressure vessel 2 The temperature is 5° C. and the pressure is 0.1 MPa. After the temperature and pressure stabilized, the isotactic polybutene-1 in CO 2 Remove after 24 hours of processing. Through X-ray diffraction analysis (XRD), it can be seen from the diffraction pattern that the characteristic diffraction peaks that characterize the crystal form II have all disappeared, indicating that the crystal form II in the treated isotactic polybutene-1 powder has completely transformed into a crystal form I; by differential scanning calorimetry (DSC), only the melting peak of the crystal form I appears in the DSC curve diagram, indicating that the crystal form II is completely transformed into the crystal form I. That is to say, in CO 2 The density is 0.0435g / cm 3 When, after 24 hours, the crystal form II was completely trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com