Method for extracting stevioside

A technology of stevioside and extraction method, which is applied in the field of plant extraction and clean production, can solve the problems of a large amount of waste water, short service life of resin, low product purity, etc., and achieve the effects of reduced waste water discharge, increased service life and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

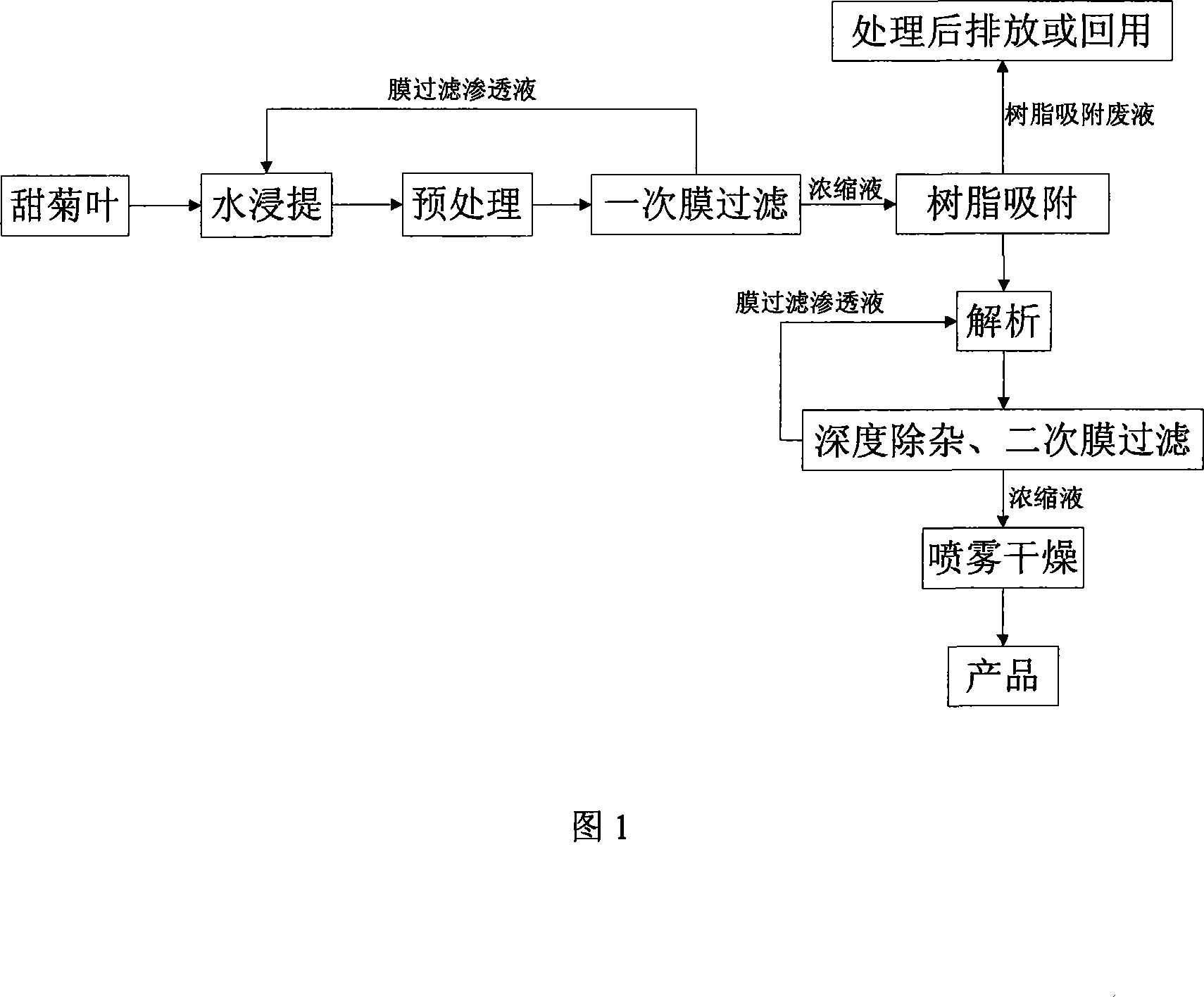

[0044] As shown in accompanying drawing 1, take by weighing 50Kg stevia leaves, soak in 1m 3 Soak in a container of water for 4 hours at room temperature, then pass through a coarse sieve to trap large leaves, and collect the permeate to obtain stevioside extract.

[0045] Add CaO to the stevioside extract to adjust pH=8, add 10Kg of FeCl 3 , then stirred at a speed of 100 rev / min for 10 min, and settled for 1 h, so that impurities such as a part of colloids and pigments were flocculated and precipitated, and the supernatant entered membrane separation pre-filtration equipment (manufactured by Nanjing Jiusi High-Tech Co., Ltd., with a membrane area of 0.1 m 2 , the following examples are the same) the supernatant is filtered by a tubular titanium metal membrane with a pore size of 200nm, and the operation mode of cross-flow filtration is adopted, the operating pressure is 0.15Mpa, and the cross-flow velocity is 1m / s. The permeate obtained through membrane separation and fil...

Embodiment 2

[0051] The extract was prepared according to the method of Example 1.

[0052] The extraction liquid is cross-flow filtered by using a tubular 19-channel zirconia ceramic membrane with a pore size of 20nm, the operating pressure is 0.75Mpa, and the cross-flow velocity is 5m / s. The permeate obtained through membrane separation and filtration enters the first-stage membrane filtration process, and the concentrated solution is added with 1 times of water for top washing, top washing three times, and then the plate and frame filter press presses the residue to make fertilizer and transport it abroad.

[0053] The primary membrane filtration process adopts roll-type polyethersulfone ultrafiltration membrane with a cut molecular weight of 1500 for cross-flow filtration, the operating pressure is 1.2Mpa, the cross-flow velocity is 0.5m / s, the concentration is 15 times, and the permeate is reused as the previous process The extraction water is used, and the concentrated liquid is proc...

Embodiment 3

[0058] Referring to the method of Example 1, the extract of stevioside was prepared.

[0059] Add NaOH to the extract to adjust the pH to 8.5, add 10Kg of polyacrylamide flocculant, then stir at 100 rpm for 15 min, and settle for 0.5 h to allow some impurities such as colloids and pigments to flocculate and precipitate, and the supernatant For membrane separation and filtration, the supernatant is cross-flow filtered by a tubular stainless steel ceramic composite membrane with a pore size of 1 μm. The operating pressure is 0.02Mpa and the cross-flow velocity is 1m / s. The permeate obtained through membrane separation and filtration enters the first-stage membrane filtration process, and the concentrated solution is added with 1 times of water for top washing, top washing three times, and then the plate and frame filter press presses the residue to make fertilizer and transport it abroad.

[0060] The first-stage membrane filtration process uses a hollow fiber polysulfone ultraf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com