Preparation method of diamond surface graphics

A surface pattern and diamond technology, which is applied in the field of diamond processing, can solve the problems of laser method that the processing capacity and processing efficiency of thin lines need to be improved, and it is difficult to prepare thin films, etc., and achieve short preparation time, easy operation, and high etching selection ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

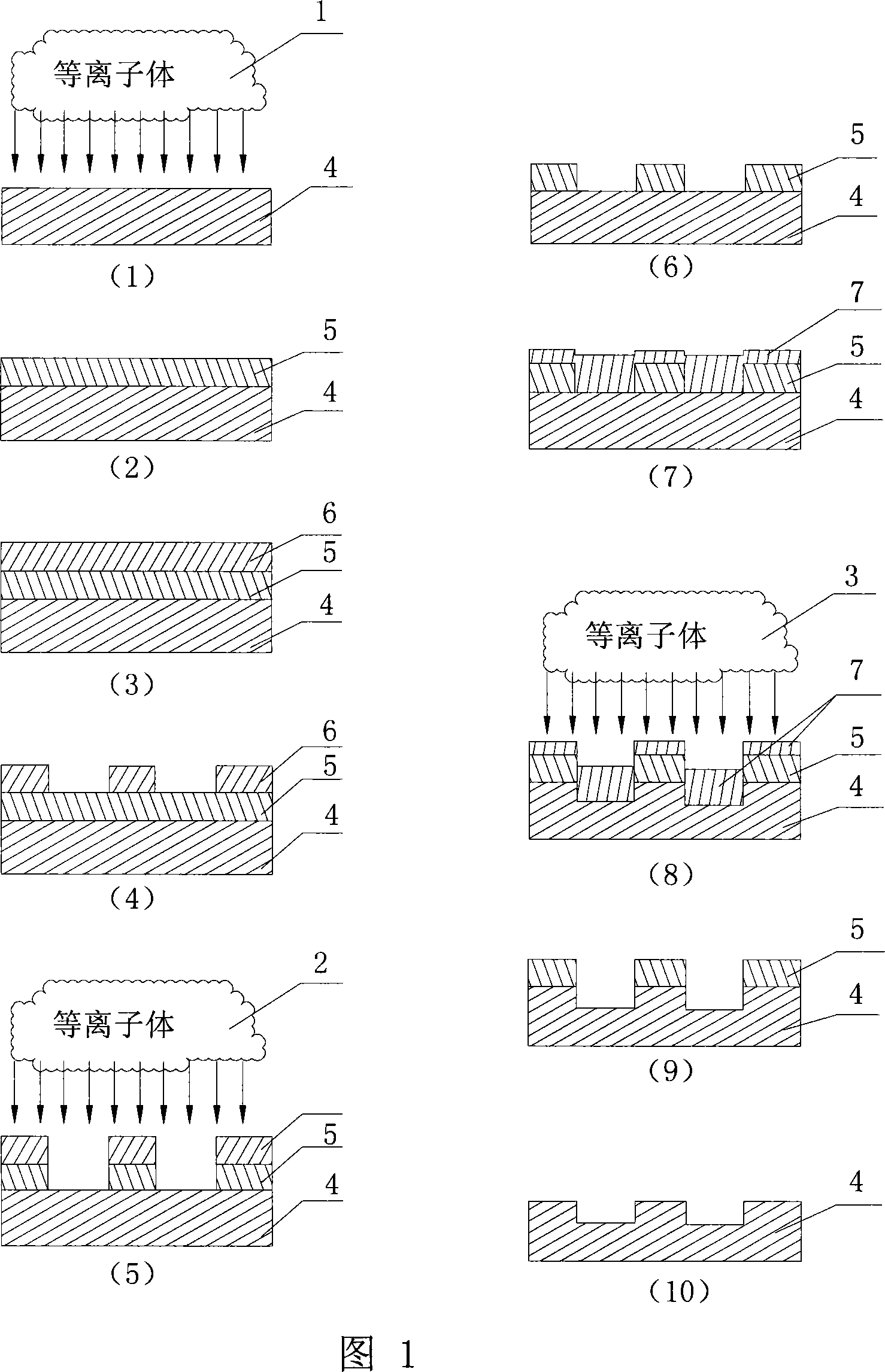

[0054] As shown in Figure 1, the preparation method of diamond surface patterning, it comprises the steps:

[0055] 1). Cleaning of the surface of the diamond sample:

[0056] Put the polycrystalline diamond film sample (diameter 30 mm, thickness 0.5 mm, surface roughness Ra<0.3 μm, i.e. diamond 4 in the figure) prepared by chemical vapor deposition method into anhydrous ethanol for ultrasonic cleaning 8 minutes, then ultrasonically washed with distilled water for 8 minutes, taken out, and baked at a temperature of 120°C for 5 minutes; put the baked diamond sample into a microwave plasma chemical vapor deposition device, and use microwave-excited plasma 1 The surface of the sample is further cleaned, and the process is as follows: working gas: hydrogen; microwave power: 300W; working pressure: 1.5kPa; processing temperature: 200°C; Time: 8 minutes. After the treatment, the diamond sample was cooled to room temperature and taken out.

[0057] 2). Preparation of the isolation...

Embodiment 2

[0072] The preparation method of diamond surface patterning, it comprises the steps:

[0073] 1) Cleaning of the diamond surface:

[0074] The diamond is selected from single crystal diamond. The diamond with a flat surface is first washed with alcohol (isopropanol) for 5 minutes, then ultrasonically washed with distilled water for 5 minutes, and then baked at 100°C for 20 minutes, and the diamond is placed in a vacuum chamber In the process, the working gas is introduced, and the working gas is argon; the working gas is excited by electric energy (such as a direct current method) to discharge and generate plasma, and the diamond surface is cleaned at a temperature of 200°C for 5 minutes, and then cooled to room temperature, Take out spare;

[0075] The process of using electric energy to stimulate plasma generation: such as the DC method, is to set two electrodes with a distance of 3-25 cm in a vacuum chamber, and these two electrodes are respectively connected to the positi...

Embodiment 3

[0093] The preparation method of diamond surface patterning, it comprises the steps:

[0094] 1) Cleaning of the diamond surface:

[0095] The diamond is selected from chemical vapor deposited polycrystalline diamond. The diamond with a flat surface is first washed with alcohol (butanol) for 20 minutes, then ultrasonically washed with distilled water for 20 minutes, and then baked at a temperature of 150 ° C for 30 minutes. In the vacuum chamber, radio frequency is used to excite the working gas to discharge it to generate plasma: in a vacuum chamber, two electrodes are set, and these two electrodes are respectively connected to the two poles of the radio frequency power supply, and the working gas (such as Ar+H 2 =10+10sccm), in the range of 0.6-20Pa, adjust the RF matcher to generate discharge between the two electrodes, the RF power is generally between 80-200W; clean the diamond surface at 300°C for 10 minutes; then cool to room temperature, remove and set aside.

[0096...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com