Preparation method for plant active carbon fibre column

A technology of plant activated carbon and plant fiber, which is applied in the field of preparation of activated carbon fiber, can solve problems such as poor spinnability and difficulty in product processing, and achieve the effects of good adsorption performance, reduced preparation cost, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

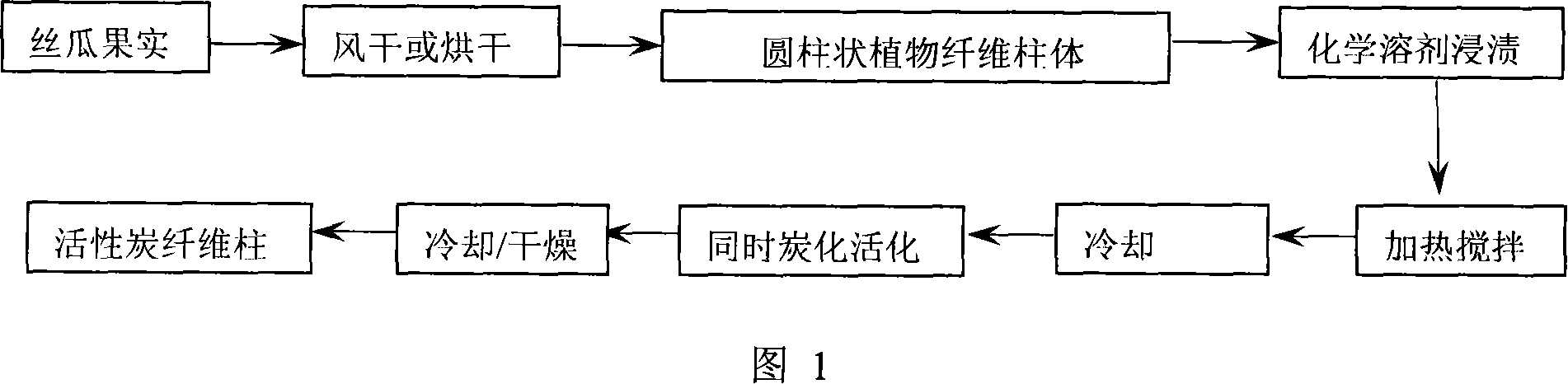

[0037] As shown in Figure 1, a kind of preparation method of plant activated carbon fiber post, it comprises the steps:

[0038] 1) after the natural air-drying of the plant loofah fruit after normal growth and maturity, the epidermis and loofah seeds are removed to obtain a cylindrical plant fiber column (or loofah) interwoven into a network;

[0039] 2) impregnating the cylindrical plant fiber cylinder in a chemical solvent;

[0040] Described chemical solvent is phosphoric acid (H 3 PO 4 ) solution, the mass concentration of the phosphoric acid solution is 0.1%, first heat the phosphoric acid solution with a mass concentration of 0.1% to 100°C, then immerse the cylindrical plant fiber column in the phosphoric acid solution with a mass concentration of 0.1%, and keep stirring for 10min , until there is obvious saponin foam leaching out in the solution, then, stop heating and stirring, let the cylindrical plant fiber cylinder and phosphoric acid mixture stand for 30min, tak...

Embodiment 2

[0046] A preparation method of plant activated carbon fiber column, it comprises the steps:

[0047] 1) after natural air-drying of the plant loofah fruit after normal growth and maturity, the epidermis and loofah seeds are removed to obtain a cylindrical plant fiber column interwoven in a net shape inside;

[0048] 2) impregnating the cylindrical plant fiber cylinder in a chemical solvent;

[0049] The chemical solvent is a phosphoric acid solution, the mass concentration of the phosphoric acid solution is 10%, the phosphoric acid solution with a mass concentration of 10% is heated to 150°C, and then the cylindrical plant fiber cylinder is immersed in the phosphoric acid solution with a mass concentration of 10%. , and continuously stirred for 20 minutes, until there is obvious saponin foam leaching out in the solution, then, stop heating and stirring, let the cylindrical plant fiber cylinder and phosphoric acid mixture stand for 40 minutes, take out the cylindrical plant fib...

Embodiment 3

[0055] A preparation method of plant activated carbon fiber column, it comprises the steps:

[0056] 1) after the fruit of the plant loofah after normal growth and maturity is dried, the epidermis and the seeds of the loofah are removed to obtain a cylindrical plant fiber column interwoven into a network;

[0057] 2) impregnating the cylindrical plant fiber cylinder in a chemical solvent;

[0058] The chemical solvent is a phosphoric acid solution, the mass concentration of the phosphoric acid solution is 30%, the phosphoric acid solution with a mass concentration of 30% is heated to 200°C, and then the cylindrical plant fiber cylinder is immersed in the phosphoric acid solution with a mass concentration of 30%. , and continuously stirred for 30 minutes, until there was obvious saponin foam leaching out in the solution, then, stop heating and stirring, let the cylindrical plant fiber cylinder and phosphoric acid mixture stand for 50 minutes, take out the cylindrical plant fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com