Fibre reinforcement plate composite foaming cement thermal insulation bricklaying and production method thereof

A composite foam cement and fiber-reinforced technology, applied to building materials, etc., can solve the problems of flammability, high cost, and non-flammability, and achieve the effects of easy handling and construction, improved molding ability, and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

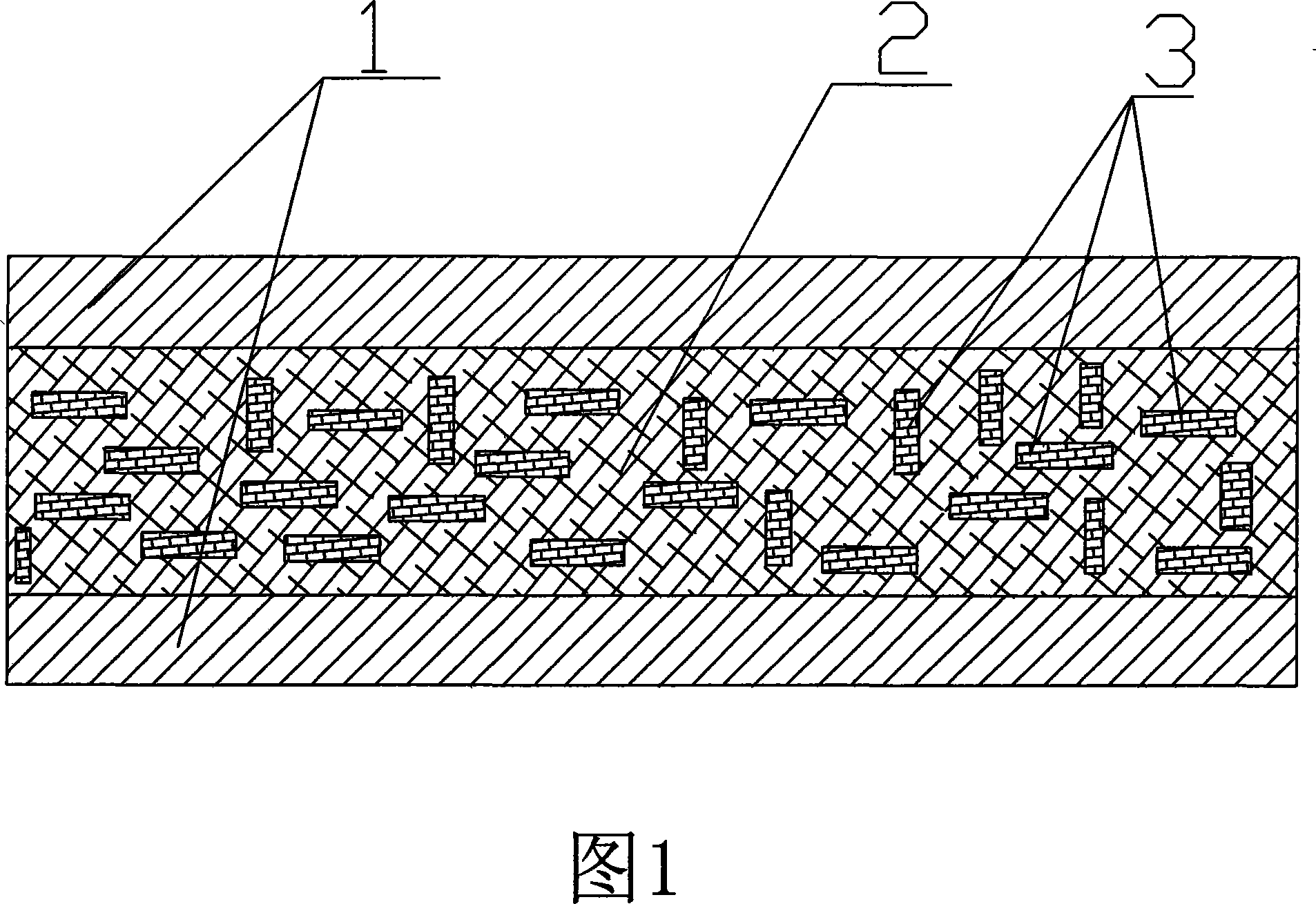

Embodiment 1

[0015] Example 1, a fiber-reinforced board composite foamed cement insulation masonry, which is composed of a fiber-reinforced board 1 and a foamed cement layer 2, two layers of fiber-reinforced boards 1 are fixedly combined with a foamed cement layer 2, and the foamed cement layer Layer 2 is mixed with reinforcement additive 3, which is one or any two or three of vitrified microbeads, fibers, and high molecular polymers. It is a mixture of foamed cement raw materials , stir evenly, and directly foam between the two fiber reinforced boards in the mold to form a foamed cement layer, so that the two sides of the foamed cement layer are respectively fixed with one side of the two fiber reinforced boards. In this embodiment, it is at 600 Place two fiber-reinforced cement boards of 600×600×20mm in a mold of ×600×250mm, use conventional known technology of animal protein foamed cement, add 2% of raw material weight fibers to the raw materials and mix them evenly, and inject them into...

Embodiment 2

[0016] Example 2, a fiber-reinforced board composite foamed cement insulation masonry is based on Example 1. In this example, two sheets of 300×300×30mm silicic acid are placed in a mold of 300×300×250mm Calcium board, using the conventional known technology of plant foaming cement, adding 20% of the raw material weight polymer to the raw material and mixing evenly, injecting it between the two boards in the mold to make the total thickness reach 240mm, place it for curing and curing, and it will be ready after 28 days Can be used, the compressive strength of the foamed cement layer is 28Kg / cm 2 .

Embodiment 3

[0017] Embodiment 3, a fiber-reinforced board composite foamed cement insulation masonry is based on Embodiment 1. In this embodiment, two 1200×600×30mm blister particleboards are placed in a mold of 1200×600×250mm , using the conventional known technology of plant foam cement, add vitrified microspheres with 40% of the weight of the raw materials to the raw materials and mix them evenly, then inject them between the two plates in the mold, so that the total thickness reaches 240mm, place them for curing and curing, and they can be used after 28 days , the compressive strength of the foamed cement layer is 38Kg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com