Light solidifying coloring composition and color filter using the same

A coloring composition, photocurable technology, applied in optics, instruments, optical components, etc., can solve the problems of limited photopolymerizable monomer content, pattern shedding or defect, sensitivity not reaching a satisfactory level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

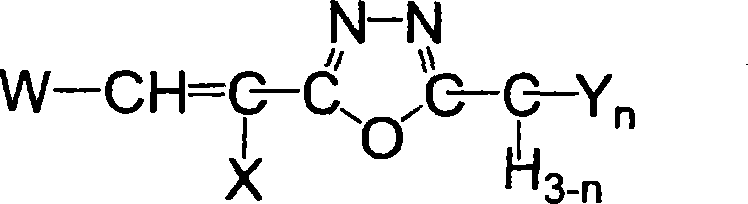

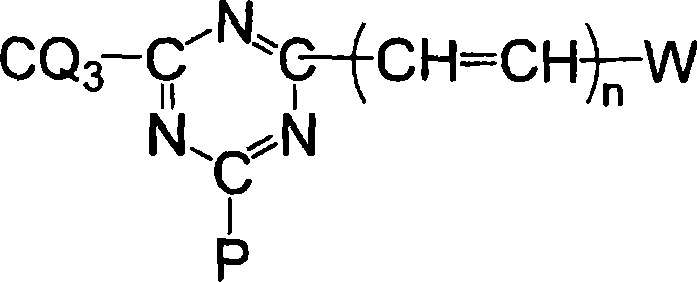

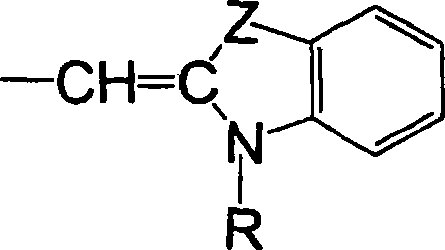

Image

Examples

preparation example Construction

[0219] Preparation of Pigments Dispersed with Dispersants

[0220] Pigments having the above average particle size and particle size distribution can be prepared by the following method. That is: mix commercially available pigments with other pigments (average particle size usually exceeding 300nm) as desired, and the above-mentioned specific dispersant and solvent to form a pigment mixture, and use a pulverizer such as a bead mill or a roller mill to form a pigment mixture. It is obtained by mixing and stirring while pulverizing. The pigment thus obtained is usually in the form of a pigment dispersion.

[0221] The above-mentioned specific dispersant is adsorbed on the surface of the pigment and plays a role of preventing re-agglomeration of the pigment. The specific dispersant is a graft type polymer having an anchoring site to the pigment surface. In order to promote the adsorption of such a polymer dispersant, it is also preferable to use a pigment derivative. As such ...

Embodiment 1

[0394] Here, the example which prepares the photocurable coloring composition α-1 containing a coloring agent (pigment), and manufactures the color filter used for liquid crystal display elements using this curable composition α-1 is demonstrated.

[0395] [1. Preparation of photocurable coloring composition α-1]

[0396] 1-1. Preparation of Pigment Dispersion (Q1): Green

[0397] 40 parts by mass of a 30 / 70 (mass ratio) mixture of C.I. Pigment Green 36 and C.I. Pigment Yellow 219 as a pigment, BYK2001 (Disperbyk: manufactured by Byk Chemie (BYK) Co., Ltd., solid content concentration: 45.1% by mass) as a dispersant 7 parts by mass (approximately 4.51 parts by mass in terms of solid content), 3 parts by mass of the specific dispersant [exemplary compound (P-1)] of the present invention, and 150 parts by mass of ethyl 3-ethoxypropionate as a solvent The resulting mixed solution was mixed and stirred with a bead mill for 20 hours to prepare a pigment dispersion (Q1).

[0398] ...

Embodiment 2~12

[0444] Of the specific initiator (compound 1), the pigment dispersion (Q1), and the specific dispersant used for the preparation of the pigment dispersion in the composition α-1 used to prepare the photocurable coloring composition α-1 Except having replaced at least one of them with the thing shown in following Table 1, it carried out similarly to Example 1, and prepared photocurable coloring composition α-2 - α-12. Using these, respectively, it carried out similarly to Example 1, and obtained the color filter which has a colored pattern. And, to the colored layer that has used pigment dispersion liquid Q4 with 200mJ / cm 2 Evaluation was performed in the same manner as in Example 1 except that exposure was performed at an exposure amount of . The results are shown in Table 1.

[0445]In addition, the structures of the specific initiators (compound 2 to compound 5) used here are shown below. In addition, as the specific dispersant, a compound selected from the above-mentione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com