Lithium/pyrite battery

An iron disulfide battery, iron disulfide technology, applied in the electrodes of primary batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problem of short storage life of semi-sealed batteries, easy aging of insulating sealing rings, and electrolyte penetration. Liquid leakage and other problems, to achieve the effect of improving the working characteristics of high current, small physical internal resistance, and reducing the speed of chemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The lithium / iron disulfide battery cathode composition and manufacturing method are as follows: 85% iron disulfide, 3.5% acetylene black, 3.5% graphite, 8% polyvinylidene fluoride are mixed, stirred for 2 hours to form a slurry, and the aluminum foil collector Put on the coating machine, adjust the height of the front and rear shutters of the coating machine, the temperature of the drying box of the coating machine is 140°C, and the coating speed is 15Hz to ensure that the thickness deviation of the coated pole piece is about 10 microns, and the coating thickness is about 300 μm. Density 48mg / cm 2 . Set the temperature of each box area, coating speed, tension control and other parameters. The prepared and stirred iron disulfide slurry is added into a material tank, coated, and dried in an oven.

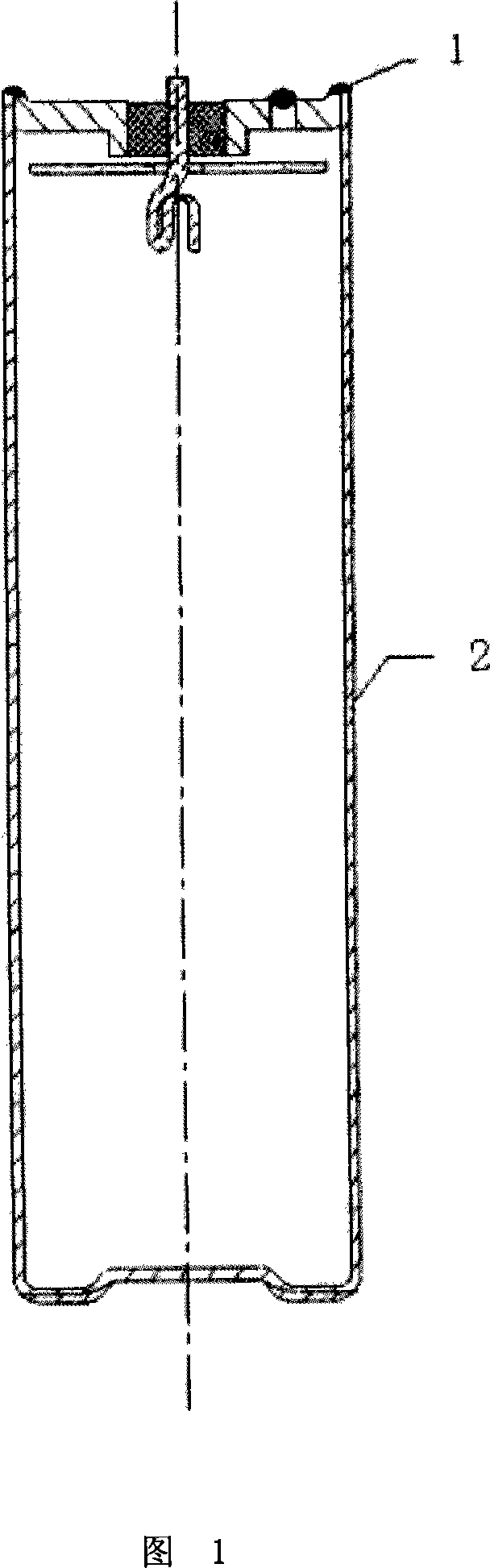

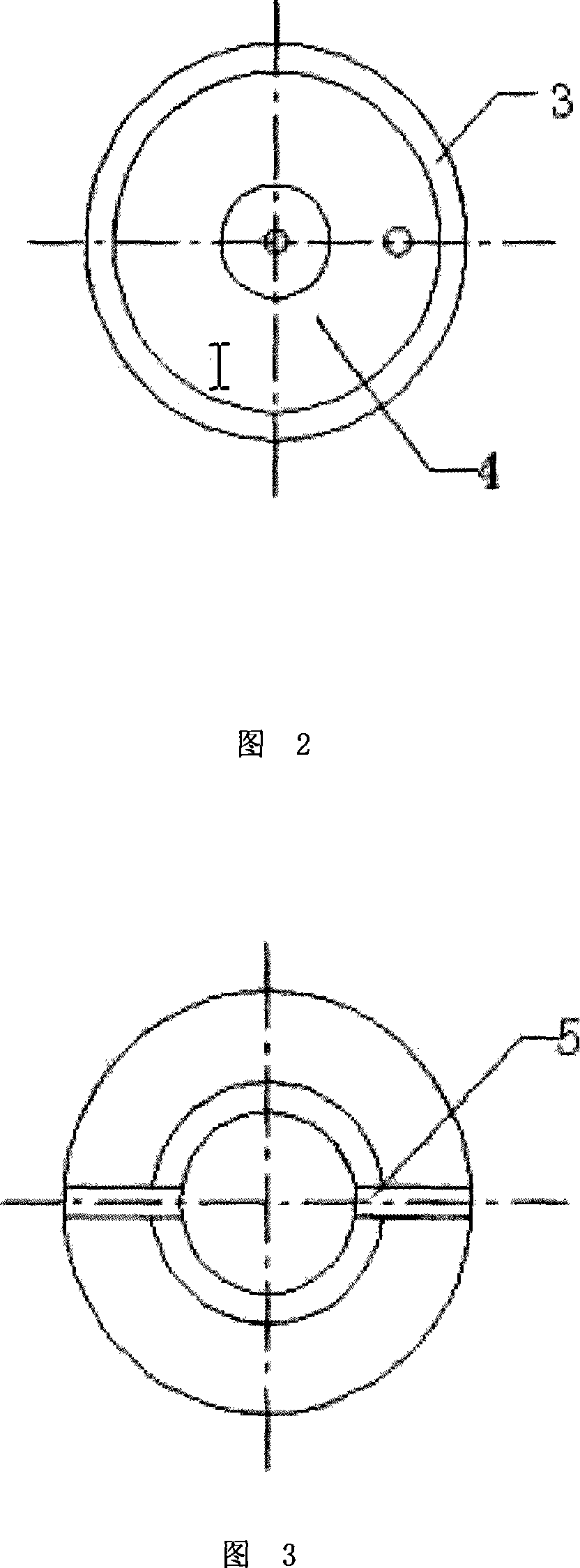

[0023] The battery shell 2 can be a stainless steel shell; the safety vent device 5 at the bottom of the shell can safely vent the battery without burning or exploding under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com