Luminescent multilayer system and utilisation thereof

A technology of objects and light-emitting layers, which is applied in the application field of light-emitting objects in optical light-emitting concentrator devices, and can solve problems such as low-efficiency coupling, low-efficiency maintenance of light, and low total efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

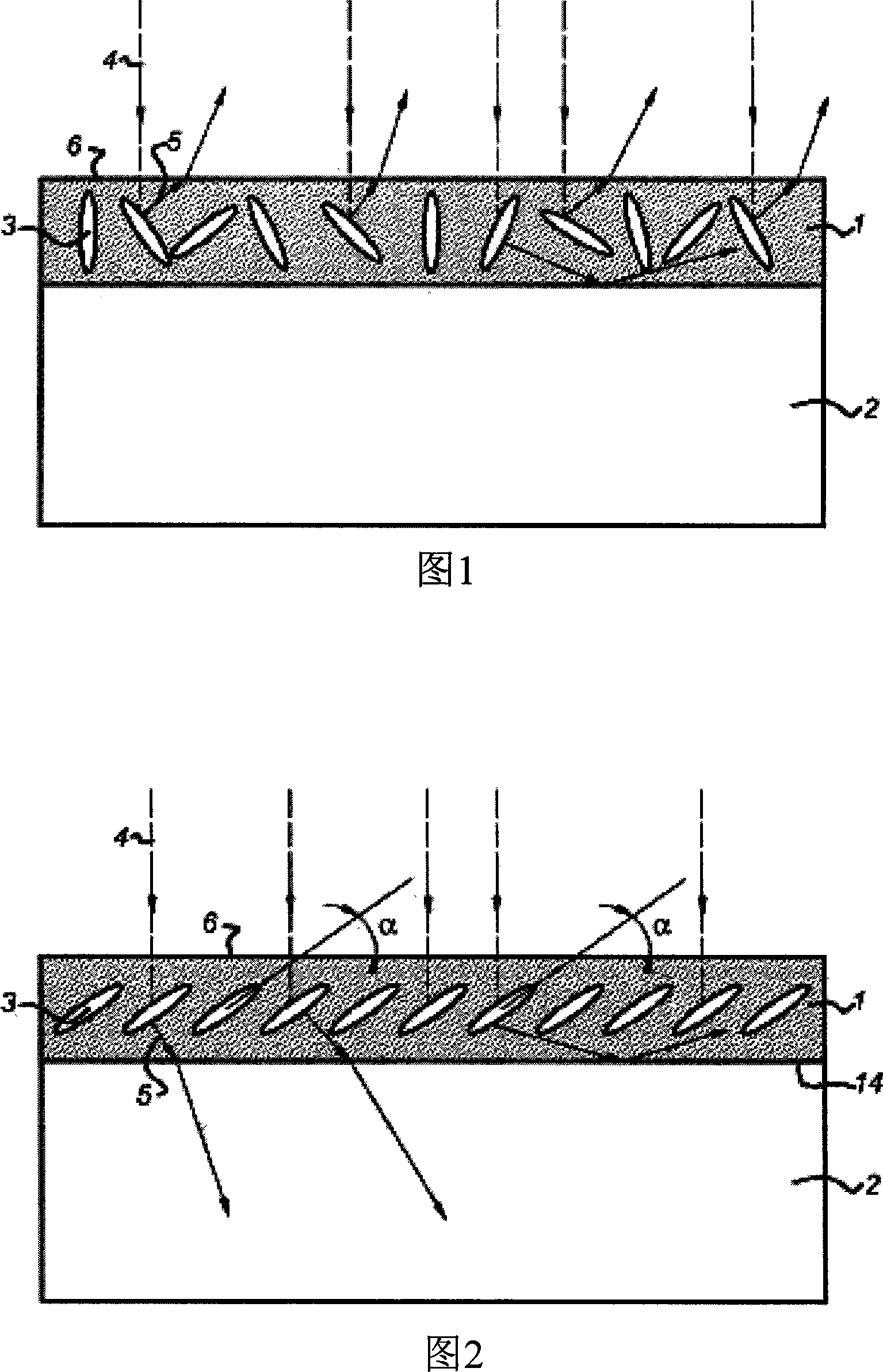

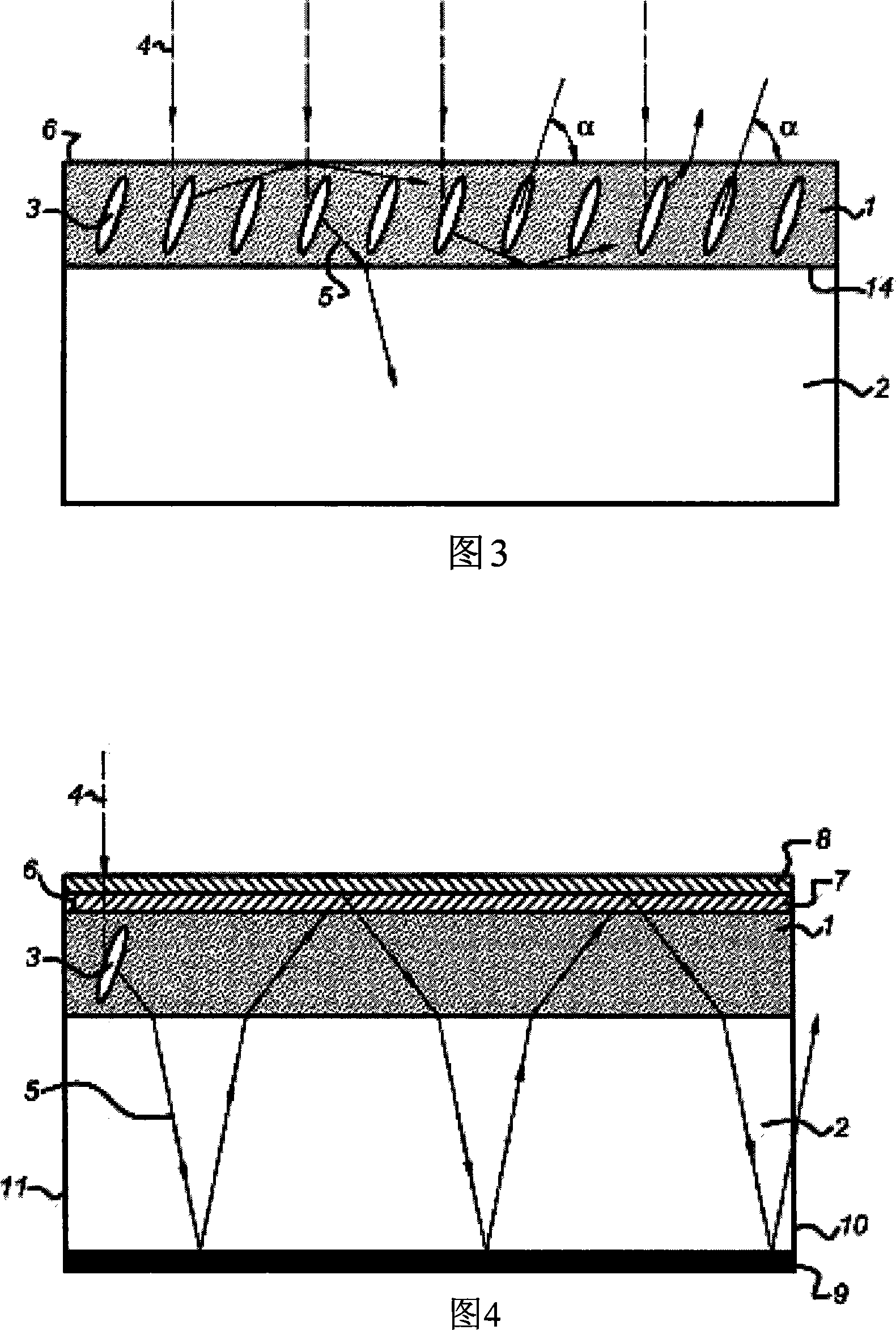

[0162] Applications of Vertically Aligned Photoluminescent Polymer Coatings

[0163] A vertical dye-doped liquid crystal mixture was applied to a clean 30 mm x 30 mm x 1 mm glass slide. The liquid crystal mixture can be obtained by mixing 1% by weight of Irgacure 184 (ex CibaChemicals) and 1% by weight of Coumarin 30 (ex Aldrich Chemicals) with a solution containing The percentage is 50% of RMM77 monomer and 50% by weight of xylene, and the weight ratio of RMM77 monomer to xylene is 1:1. RMM77 (Merck) is a nematic vertical active liquid crystal, and its main components are liquid crystals RM82 and RM257 (both Merck) and vertical dopants. The mixture was stirred at 80°C for 2 hours until all the ethanol had evaporated. Xylene can be evaporated by placing the mixture on a preheated waveguide (80° C.) for 10 minutes. After evaporating the xylene, wet films were prepared using a 24 um Meyer rod to produce a film about 10 um thick. The sample is at room temperature, under N 2 ...

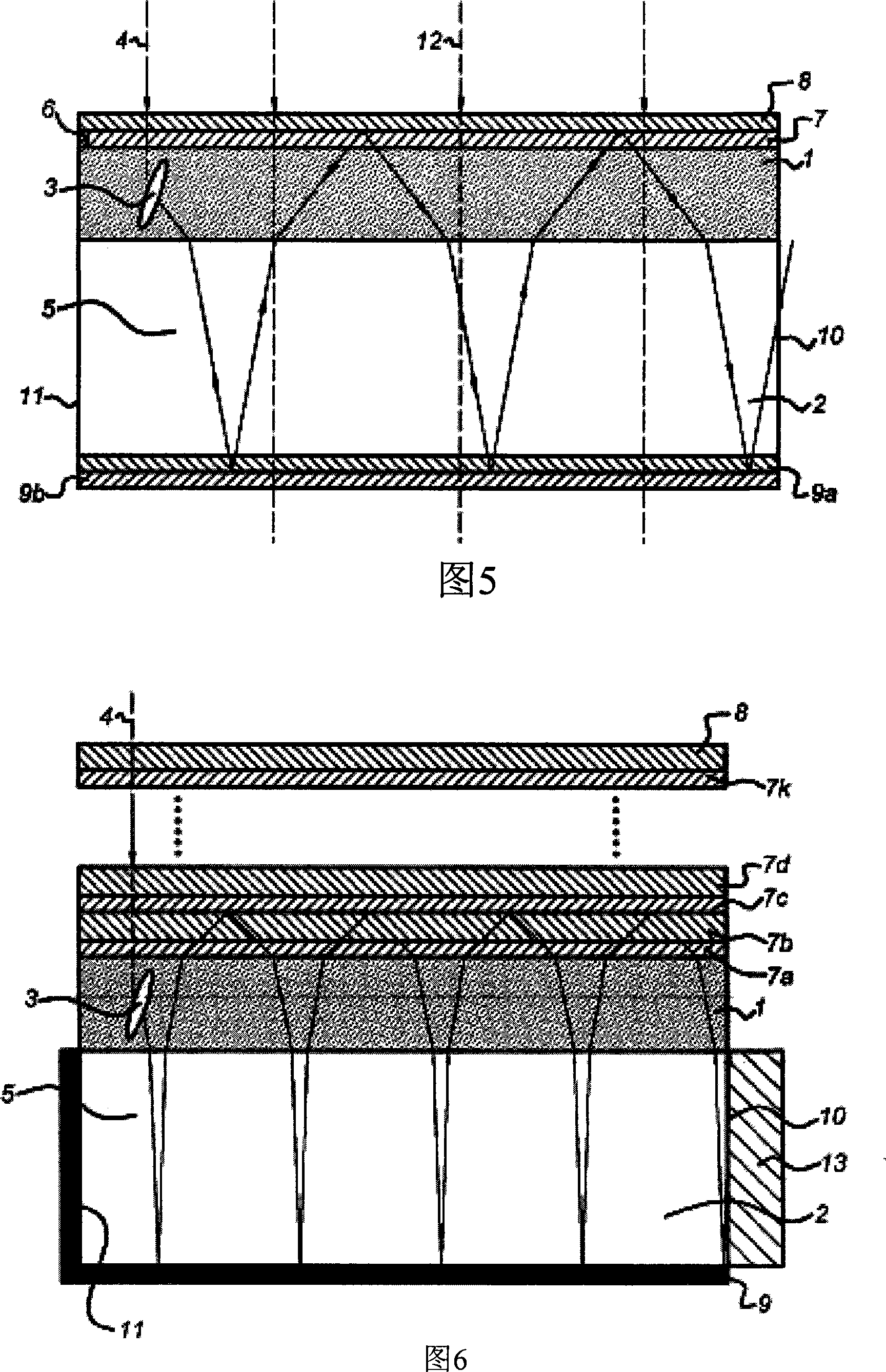

Embodiment 2

[0170] A clean glass substrate (Optimer A1 1051, ex JSR Micro) with a polyimide alignment layer, and the polyimide alignment layer is 2500 rpm / s at a speed of 2000 rpm / s 2 Spin-coating of accelerations for 45 s was obtained. The substrate was then heated at 180° C. in vacuum for 1.5 hours. The alignment layer was rubbed with a velvet cloth to bring about planar alignment of the cholesteric liquid crystals used. The vertical dye described in Example 1 was then doped into the liquid crystal mixture (this time using the dye DCM(4-(dicyanomethylene)-2-methyl-6-(4-dimethylaminostyryl)-4H -pyran) (ex Aldrich Chemicals)) was applied to the opposite side of the substrate.

[0171] The mixture was prepared by mixing 1% by weight of Irgacure 184 (ex Ciba Chemicals) and 1% by weight of Dipentaerythritol Pentaacrylate (Aldrich) at 75% by weight and 25% by weight of % ethanol solution mixed. A thin film approximately 10 m thick can be formed by spin coating at 4000 rpm for 45 seconds (...

Embodiment 3

[0188] Example 1 was repeated except that a liquid crystal polymer was used, and the liquid crystal polymer was obtained by using the process described in Sinha et al in Appl. Phys. Lett. (2001), 79(16), 2543-2545, along Arranged at an inclination angle of about 30°.

[0189] The efficiency of the LSC was measured again using the method described in Example 1. The results show that the efficiency of this LSC exceeds that of the LSCs described in Examples 1 and 2. This excellent efficiency is believed to be related to the enhanced coupling of the emitted radiation into the waveguide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com