Micro-heat current gyroscopes

A gyroscope and micro-heating technology, applied in the field of sensors, can solve the problems of jet deflection, gyroscope processing complexity, and the inability to achieve the optimum at the same time, and achieve the effects of overall size reduction, high convective heat transfer efficiency, and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

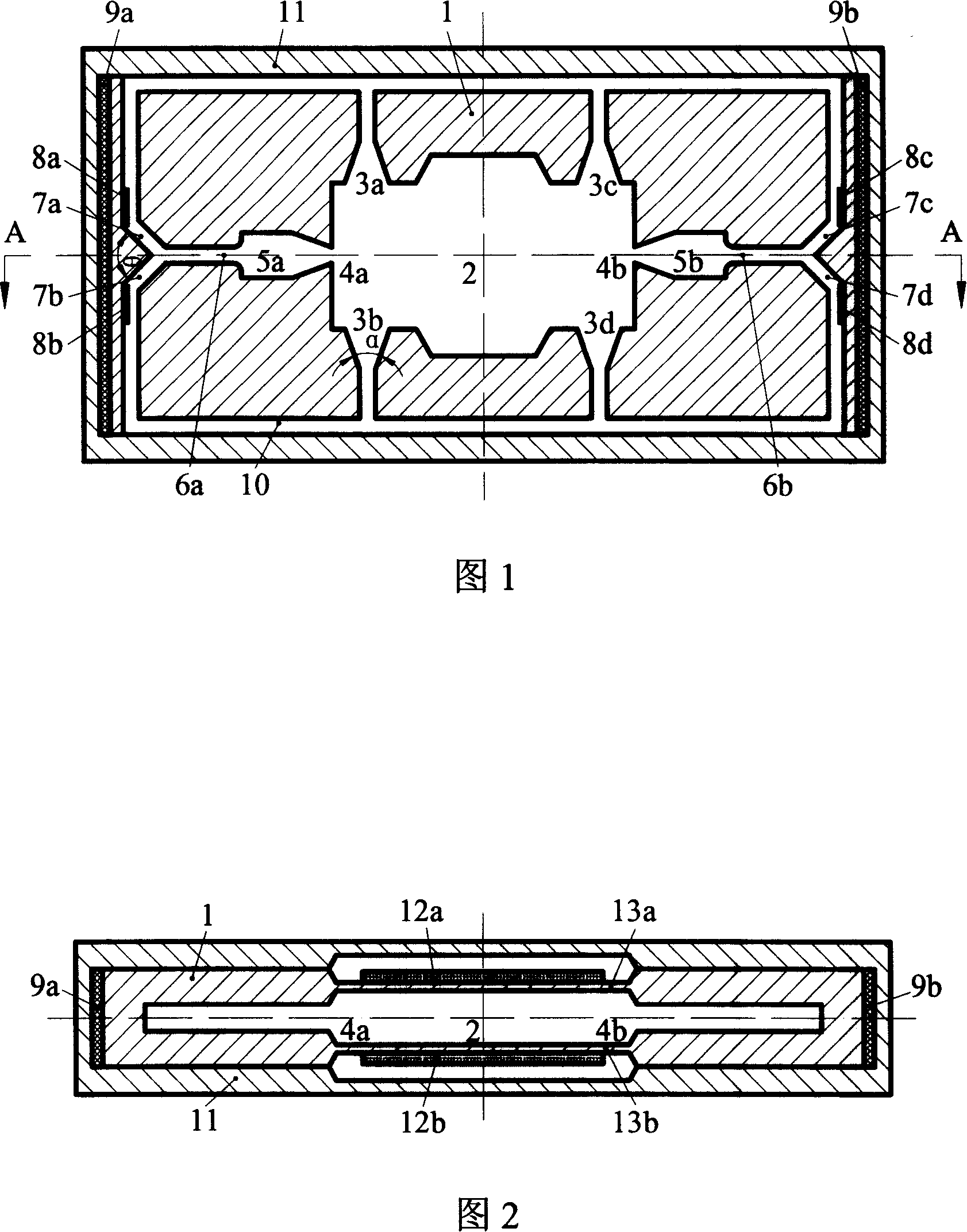

[0020] Referring to Fig. 1 and Fig. 2, a cavity 2, a first tapered shrink tube 3a, a second tapered shrink tube 3b, a third tapered shrink tube 3c, a fourth tapered shrink tube 3d, and a fourth tapered shrink tube 3d are opened on the base body 1. A tapered diffuser tube 4a, a second tapered diffuser tube 4b, a first buffer chamber 5a, a second buffer chamber 5b, a first main microfluidic channel 6a, a second main microfluidic channel 6b, a first shunt channel 7a, a second Two shunt passages 7b, a third shunt passage 7c, a fourth shunt passage 7d, and a return pipe 10. The cavity 2 is located at the center of the base body 1. The first tapered shrink tube 3a and the second tapered shrink tube 3b pass through the cavity 2, The first tapered diffusion tube 4a, the first buffer chamber 5a, and the first main microfluidic channel 6a are respectively connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com