Phosphor in polycrystalline ceramic structure and a light-emitting element comprising same

A technology of polycrystalline ceramics and light-emitting elements, which is applied in the field of phosphors and can solve problems such as high cost, back scattering, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

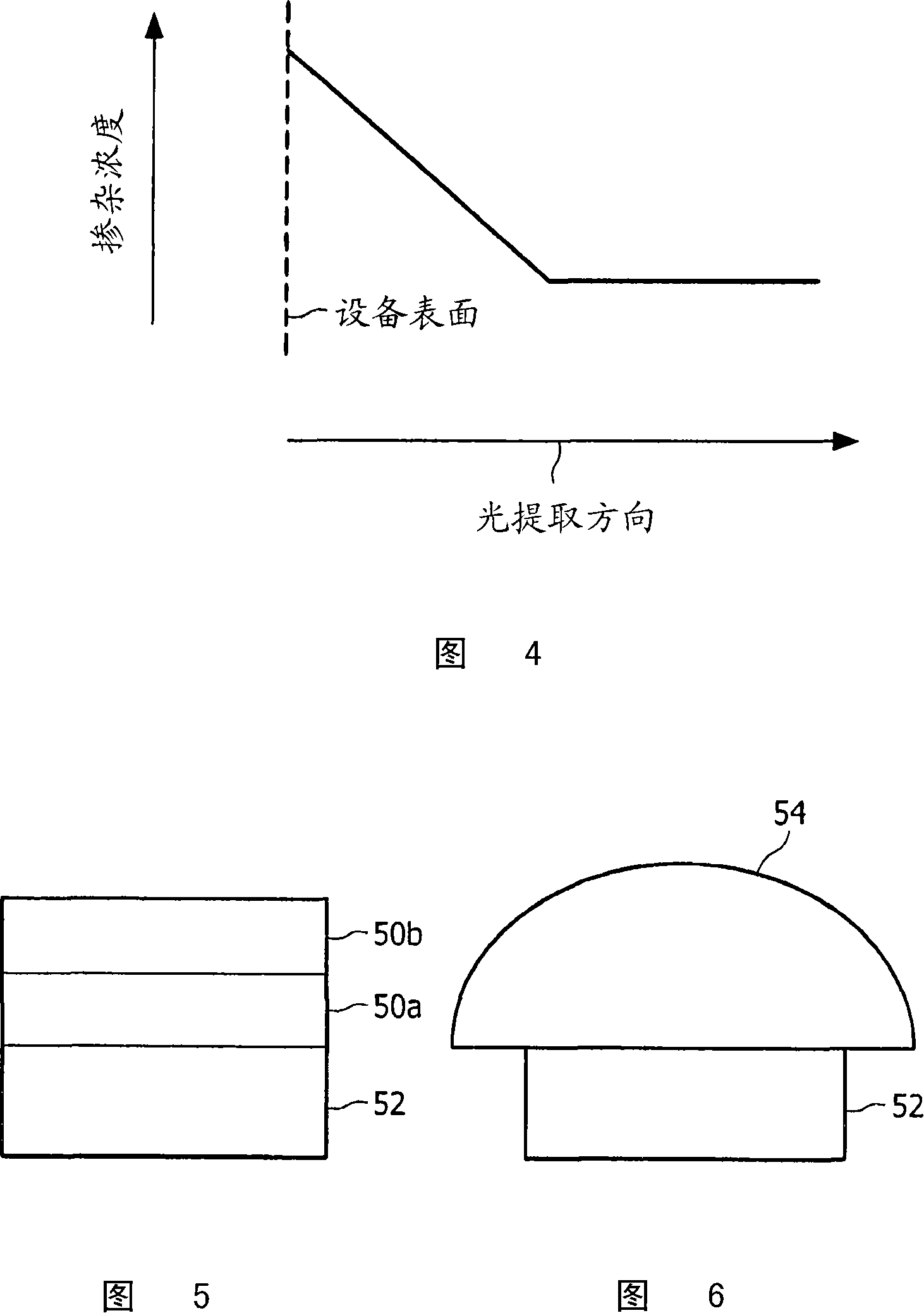

[0054] By deagglomeration of alumina particles (for example by wet ball milling (wet ball milling) or ultrasound, etc.) and stabilization (for example by using HNO 3 or polyacrylic acid), a powder consisting of fine and well-dispersible alumina particles (e.g. Taimei TM-DAR, Sumitomo AKP50) is mixed with a YAG:Ce type powder dispersed in water (e.g. Philios Lighting) . The alumina suspension is cast (for example by slip casting or gel casting) into the mold.

[0055] After drying and removal from the mold, the porous alumina product is calcined in oxygen at a temperature substantially below the sintering temperature to remove all unwanted components such as stabilizers and binders. Next, the material is sintered in a suitable sintering atmosphere (such as vacuum or oxygen atmosphere) until the density is higher than 95%. Hot isostatic pressing is performed after the sintering process to further increase the density without requiring higher sintering temperatures. The result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com