Method for preparing surface cladding super-micro traditional Chinese medicine material crude slice

A technology of surface coating and decoction pieces of traditional Chinese medicine, which is applied in the direction of medical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of reducing the effective use of traditional Chinese medicines, and achieve improved fluidity and fast dissolution , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

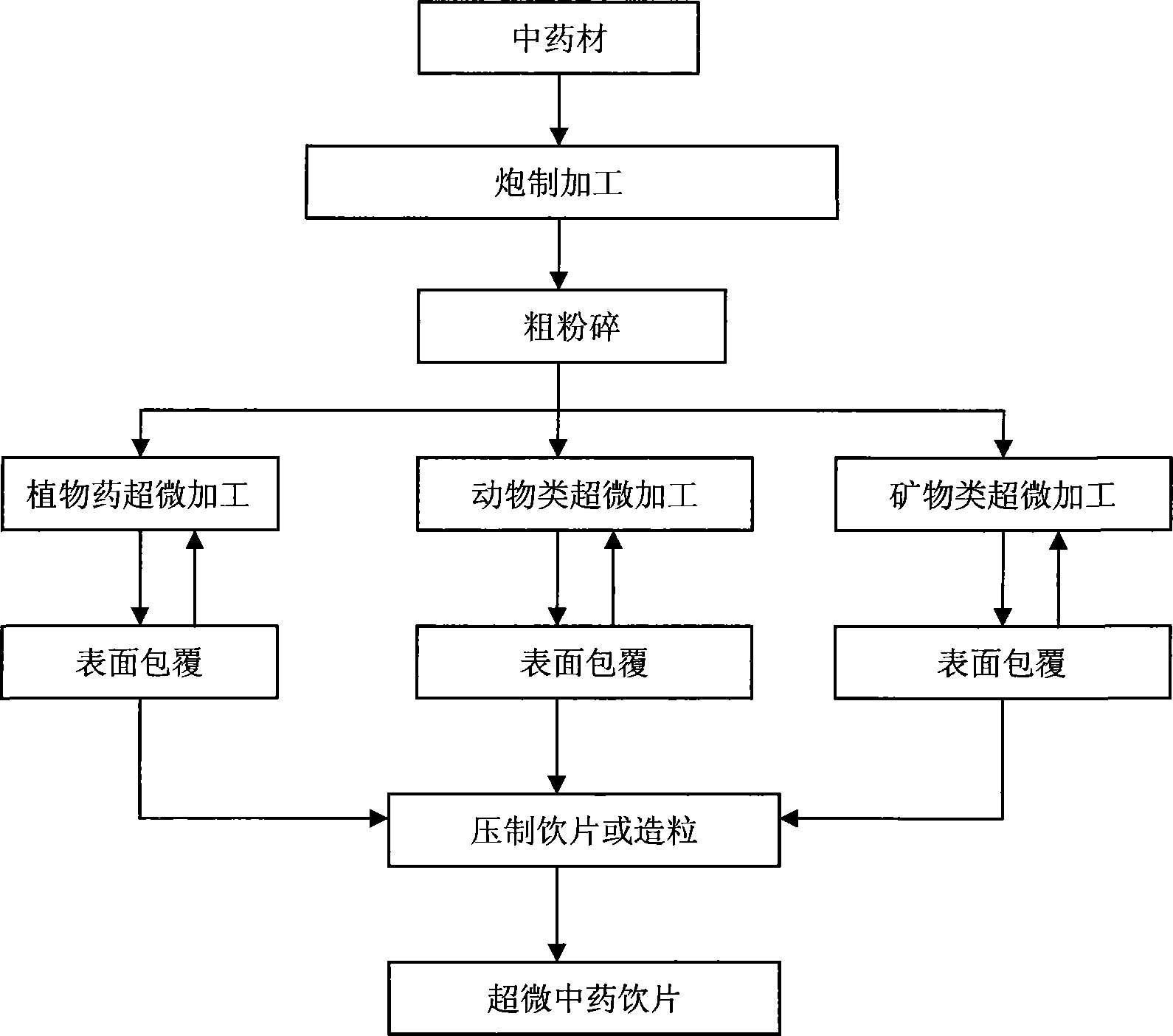

[0008] As shown in the accompanying drawings, the preparation method of the surface-coated ultrafine Chinese herbal decoction pieces of the present invention includes the steps of processing, coarse pulverization, ultrafine pulverization, tabletting or granulation. Coating modification to prevent the loss or oxidative decomposition of active ingredients, the specific preparation steps are as follows:

[0009] 1. First, wash and dry the traditional Chinese medicine, and then carry out standardized processing according to the conventional technology, which is the basis of the processing of Chinese herbal medicine slices.

[0010] 2. Coarsely pulverize the processed traditional Chinese medicine. The coarse pulverization is carried out by mechanical pulverization, and pulverized into coarse particles with a particle size of 20-80 mesh for ultramicroprocessing.

[0011] 3. Ultra-micro processing is based on the different crushable characteristics of Chinese herbal medicines, and th...

Embodiment 1

[0019] Take 500 grams of wolfberry, clean and dry according to the conventional processing method; adopt the method of mechanical crushing to carry out coarse crushing to 20 mesh; adopt airflow crushing process to carry out circular crushing to 1500 mesh (8 microns). The surface coating agent gelatin is introduced into the circulation crushing process, the dosage of the surface coating agent is 5%, the gelatin is mixed with the solvent in a certain proportion, and directly enters the circulation crushing system. Due to the high polysaccharide content of Lycium barbarum, the total sugar content reaches 35-45%, and the active polysaccharide content reaches 6-10%, it is difficult to carry out ultramicronization treatment, and it is very easy to absorb moisture and agglomerate. After being processed by the method of the present invention, the ultramicronized Lycium barbarum is not only easy to crush, but also has good fluidity, and can be conveniently processed for decoction pieces...

Embodiment 2

[0021] Get 500 grams of ganoderma lucidum spore powder, at first raw material is carried out quality control, to guarantee to meet relevant requirements. Because the particles of Ganoderma lucidum spore powder itself are very small, it can be directly subjected to ultramicronization processing to meet the requirement of wall breaking. However, after the Ganoderma lucidum spore powder is broken, the active ingredients such as Ganoderma lucidum polysaccharides and polypeptides, which are rich inside, adhere to the ultrafine pulverizer, which seriously affects the crushing flow field and reduces the crushing effect, and these active ingredients are also very easy to be polluted or decomposed. In this wall-breaking process, a surface coating agent is introduced, and starch and β-cyclodextrin are used for coating, and the dosage of the coating agent is 1%. After surface coating, the content of ganoderma lucidum polysaccharide and other components can be kept basically unchanged, up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com