Fabric product with antibiosis, deodorization, heat emission and cooling function

A fiber product, cool technology, applied in the field of fiber products, can solve the problems of inconvenience, general products without structure, stuffy heat, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

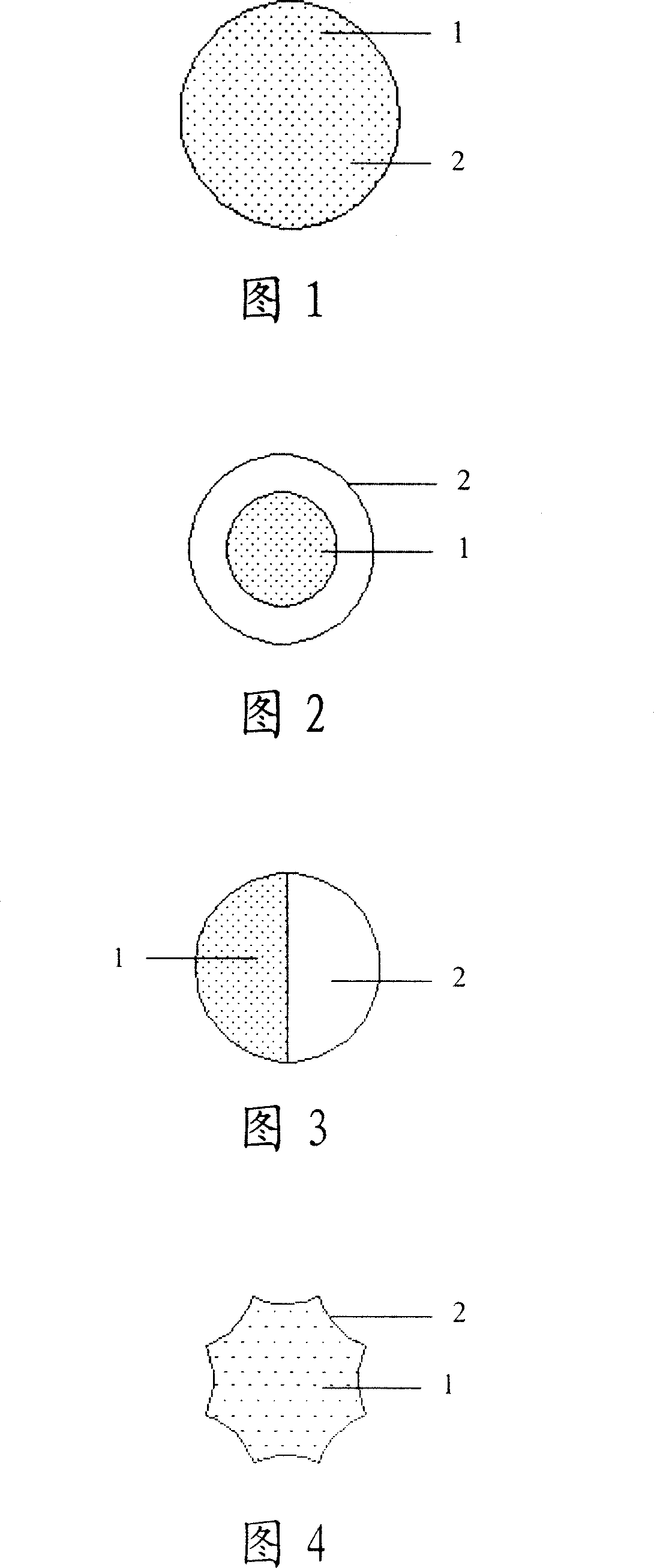

[0049] The production method of the product of the present invention is to use sub-micron-level high thermal diffusivity and low thermal conductivity and trace rare earth powders. After the uniform dispersion treatment of the surfactant, the dispersed powder is added to the thermoplastic Type polyamide plastic granules, which are fully and evenly mixed by a kneader, and then made into a masterbatch by a granulator, and finally made into 110d / 24f nylon partial extension yarn (Partial Oriented Yarn, POY) by melt spinning technology , and finally a 70d / 2Δf nylon draw textured yarn (Draw Textured Yarn, DTY) is made by a stretch false twist machine. And according to the design of the spinning nozzle, it can be made into continuous filament nylon fibers with different cross-sectional shapes (as shown in Figure 1 to Figure 4), fineness, color, structure, etc. Using 70d / 24f nylon DTY as the warp and weft yarns, the water-jet shuttleless loom is used to make woven fabrics of various st...

Embodiment 2

[0051] The production method of the product of the present invention is to use sub-micron powder with high thermal diffusivity and low thermal conductivity. After the uniform dispersion treatment of surfactant, the dispersed powder is added to vinyl alcohol (Ethylene Glycohol, EG) And with terephthalate acid (TerephathalateAcid, TPA), the implementation of condensation polymerization reaction to produce thermoplastic polyester pellets, and then through melt spinning (Melting Spinning) first spun into 120d / 36f partially extended yarn (Partial Oriented Yarn, POY), and finally make 75d / 36f extended false twisted yarn (DrawTextured Yarn, DTY) through the extended false twisting machine. With the DTY of 75d / 36f as the warp and weft yarns, the water-jet shuttleless loom becomes a fiber product with both antibacterial, odor-absorbing and cooling properties. And the design of the spinning nozzle can be changed to make fiber products of various cross-sectional shapes, fineness, structu...

Embodiment 3

[0053]The production method of the product of the present invention is to use submicron composite powder with high thermal diffusivity and low thermal conductivity. Propylene plastic granules are fully and evenly mixed through a mixer or kneader, and then made into masterbatches through a granulator. Finally, the melt-blown non-fabric (MeltBlown) technology is used to manufacture antibacterial and odor-absorbing materials through pre-designed spinning nozzles. Cool fiber products with heat dissipation. The product of the present invention refers to the Japanese JAFET deodorization performance evaluation test method, and its deodorization rate can reach more than 70%. And because of the sub-micron composite powder with high thermal diffusivity and low thermal conductivity added to the polypropylene fiber, after being irradiated by a 500W halogen lamp, the overall endothermic and exothermic curves can be monitored by a thermal image analyzer, which can be used in a short time ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com