High-temperature resistant insulation continuous sheet and manufacturing method thereof

A continuous sheet, high temperature-resistant technology, applied in synthetic cellulose/non-cellulose material pulp/paper, textiles and papermaking, papermaking, etc., can solve the problems of high water content of finished paper, decreased insulation performance, cumbersome manufacturing technology, etc. Achieve good uniformity, improve heat resistance, uniform cohesion and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

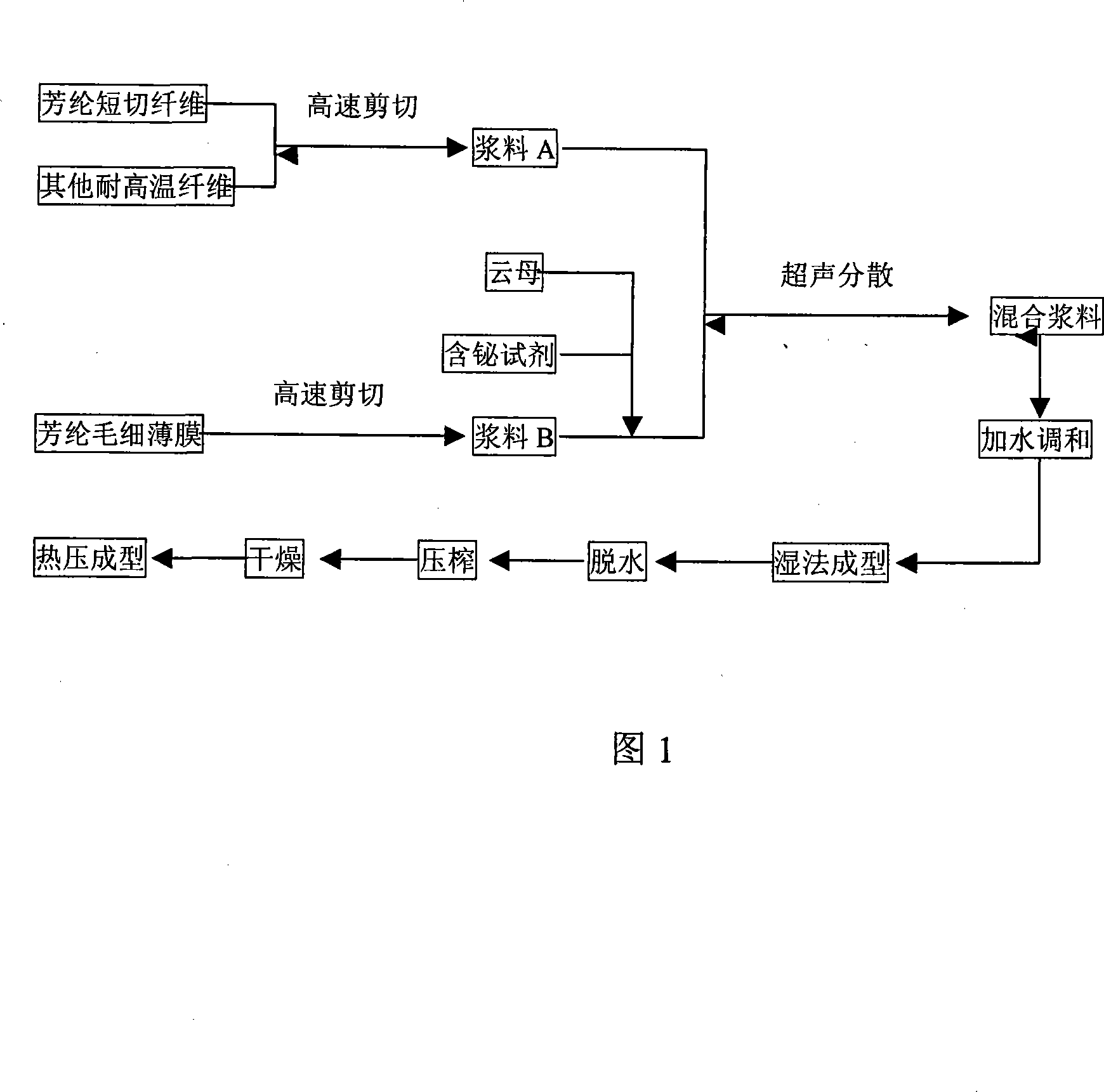

Image

Examples

Embodiment 1

[0030] Embodiment 1: in 30 kilograms of water, add 30 gram lengths and be the polym-phenylene isophthalamide chopped fiber of 6mm, 15 gram lengths are the terephthalamide p-phenylenediamide chopped fiber of 3mm, 10 grams Length is the polyimide short-cut fiber of 6mm, obtains slurry A after dispersing under the stirring velocity of 2000 rev / mins; In 20 kilograms of waters, add the polym-phenylene isophthalamide capillary film of 20 grams, 15 The polysulfone amide capillary film of gram obtains slurry B after being dispersed at the stirring velocity of 2000 rev / mins; 2 Further mixing and dispersing under ultrasonic waves, and simultaneously adding 6 grams of mica and 2 grams of bismuth acetate to obtain a mixed slurry. Wherein the solid content is about 0.5wt%, and 150 kg of water is added before wet forming. The mixed slurry is formed by wet method, squeezed, dried and hot-pressed with a rolling mill at 240° C. under a linear pressure of 180 kg / cm to obtain a finished product...

Embodiment 2

[0031] Embodiment 2: add 400 gram lengths in 60 kilograms of water and be the polym-phenylene isophthalamide chopped fiber of 4mm, 50 gram lengths are the poly-paraphenylene terephthalamide chopped fiber of 5mm, 150 Gram length is the PBO chopped fiber of 6mm, obtains slurry A after dispersing at the stirring velocity of 2800 rev / mins; In 40 kilograms of water, add the capillary film of 150 grams of m-phenylene isophthalamide, 150 grams of poly Sulfone amide capillary film, after dispersing at a stirring speed of 2200 rev / min, slurry B is obtained; 2 Further mix and disperse under ultrasonic waves, and simultaneously add 100 grams of mica and 20 grams of bismuth acetate to obtain a mixed slurry, wherein the solid content is about 1 wt%. This mixed slurry is mixed with 25 kg of water to form a slurry with a total solid content of 0.8%, which is wet-formed, squeezed, dried, and hot-pressed with a rolling mill at 270°C with a line pressure of 193kg / cm to obtain a finished product...

Embodiment 3

[0032] Embodiment 3: in 60 kilograms of water, add 200 gram lengths and be the polym-phenylene isophthalamide chopped fiber of 4mm, 80 gram lengths are the poly-paraphenylene terephthalamide chopped fiber of 3mm, 40 Gram length is the polyimide chopped fiber of 6mm, and 30 grams of length are the PBO chopped fiber of 6mm, obtain slurry A after dispersing under the stirring speed of 2450 rev / mins; Add 120 grams of polyimide in 40 kilograms of water Phthalamide m-phenylenediamine capillary film, the polysulfone amide capillary film of 80 grams, obtain slurry B after dispersing at the stirring speed of 2080 rev / mins; The above-mentioned three kinds of dispersed A and B slurry are continued to stir At the same time, at a power of 800w / m 2 Further mixing and dispersing under ultrasonic waves, and simultaneously adding 32 grams of mica and 19 grams of bismuth acetate to obtain a mixed slurry. Wherein the solid content is about 0.5wt%. Add 400 kg of water to the mixed slurry and mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com