Thermometer for stepper motor drive finger

A stepper motor and thermometer technology, applied in the field of thermometers, can solve the problems of zero point and full scale drift, troublesome debugging process, reduced elasticity and service life, etc., to achieve simple zero point adjustment and full scale adjustment, and reduce manual operation time. , to ensure the effect of adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

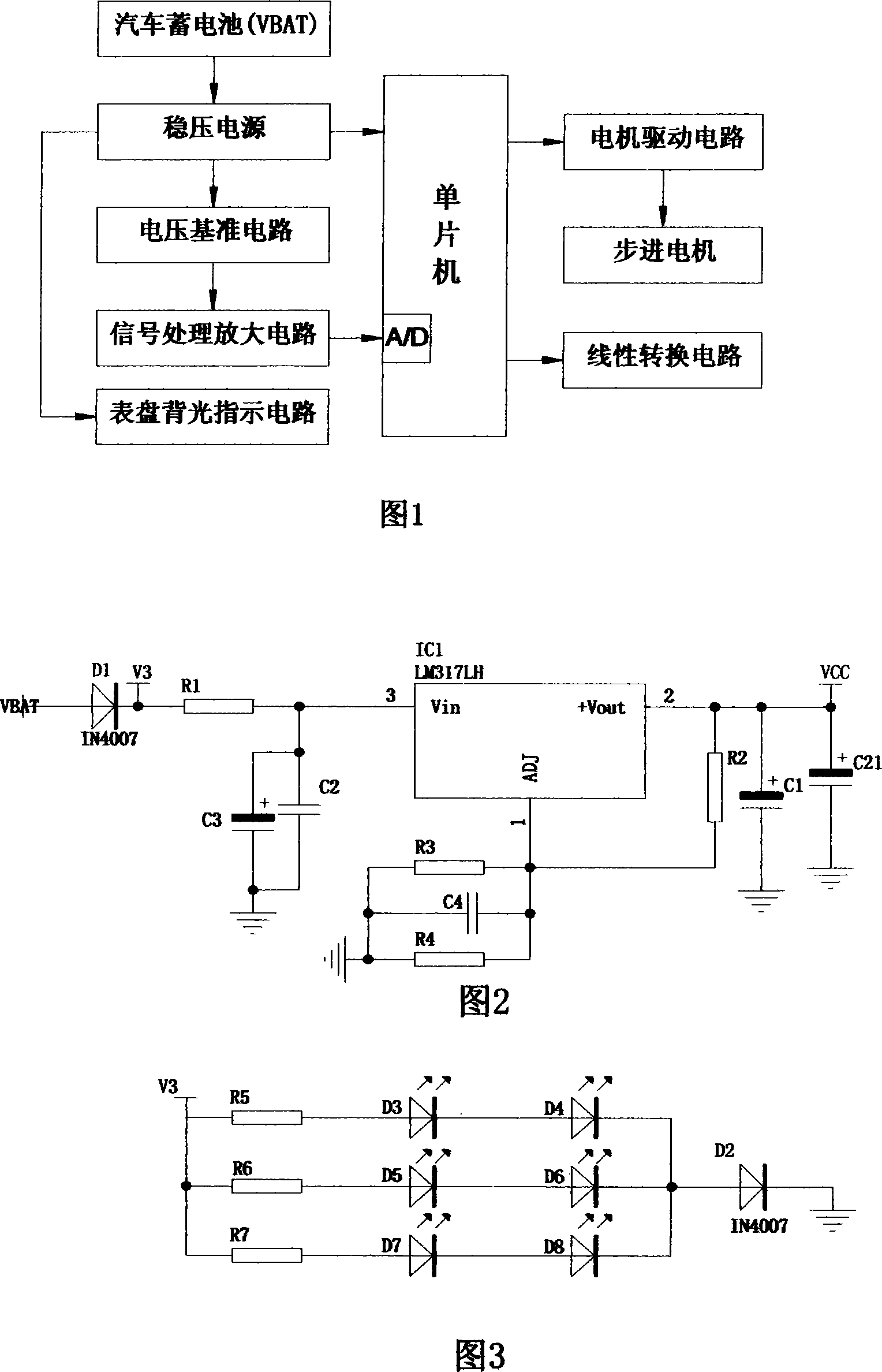

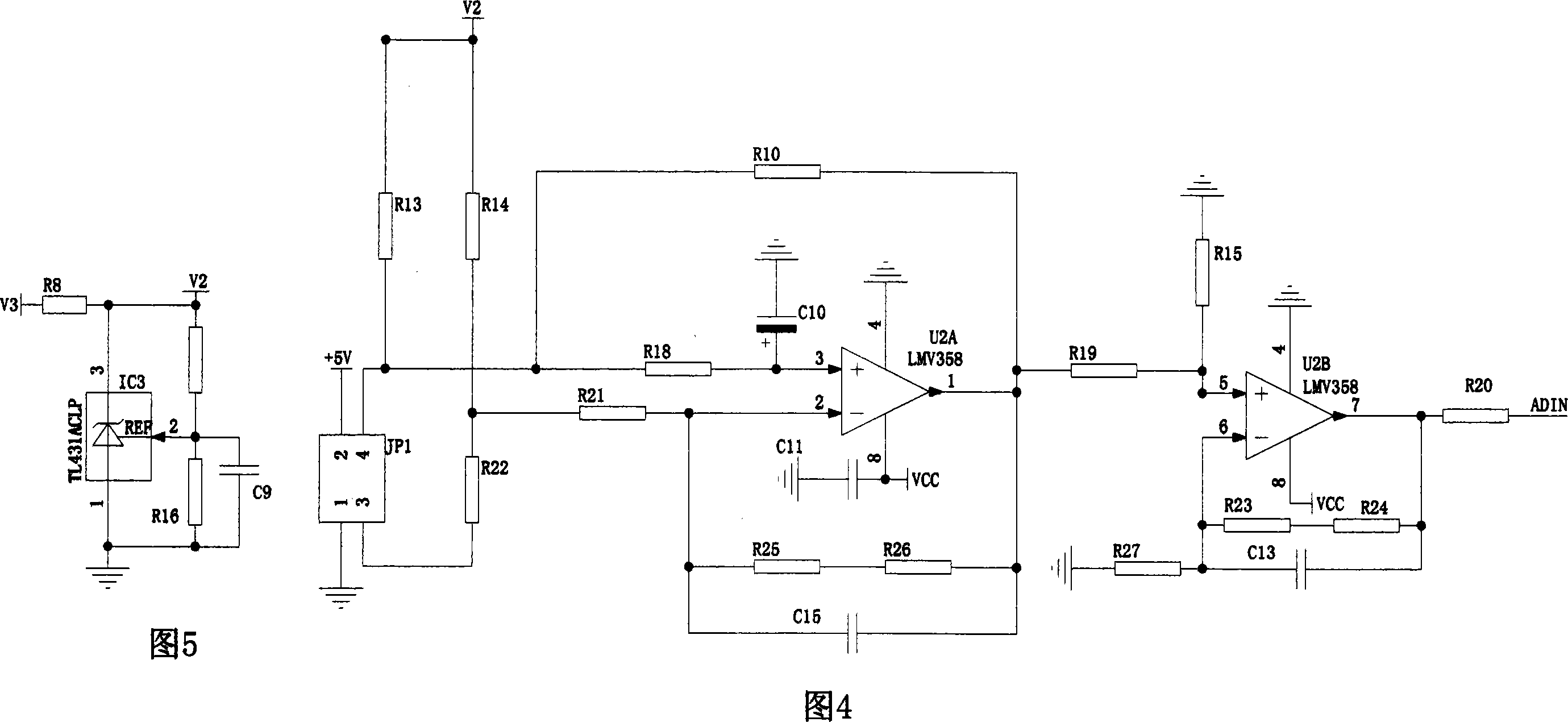

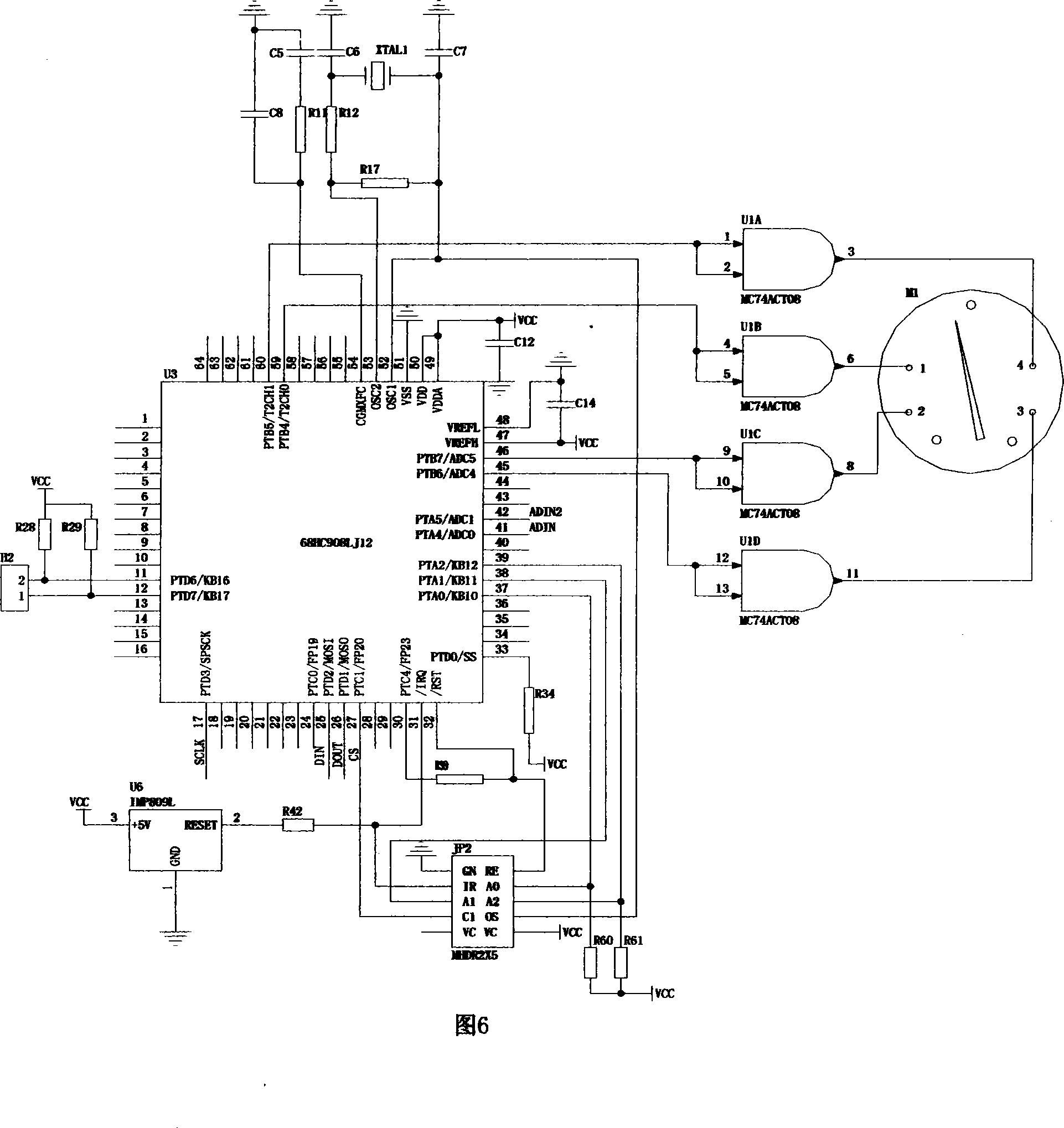

[0018] With reference to Fig. 1 and Fig. 2, the thermometer of stepping motor-driven pointer of the present invention, the output voltage VBAT of automobile accumulator, the voltage range of VBAT is between 20V to 28V, is respectively connected with stabilized power supply and backlight indication circuit by wire. The anode of the diode D1 in the regulated power supply is connected to VBAT; the cathode of the diode D1 leads to a power supply V3, and the voltage of the power supply is 24V. The cathode of diode D1 is connected to resistor R1. Resistor R1, capacitor C2 and electrolytic capacitor C3 form a current-limiting filter circuit. The current-limiting filter circuit limits the power supply current through resistor R1. At the same time, capacitor C2 and electrolytic capacitor C3 filter out high-order harmonics. Make the regulated power supply have the performance of withstanding group pulse interference and the immunity of electrical transient conduction. The other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com