In situ preparation method for nano WC powder from porous carbon material

An in-situ synthesis, porous carbon technology, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problems of many processes, unfavorable mass production, high cost, achieve control, good economy, simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

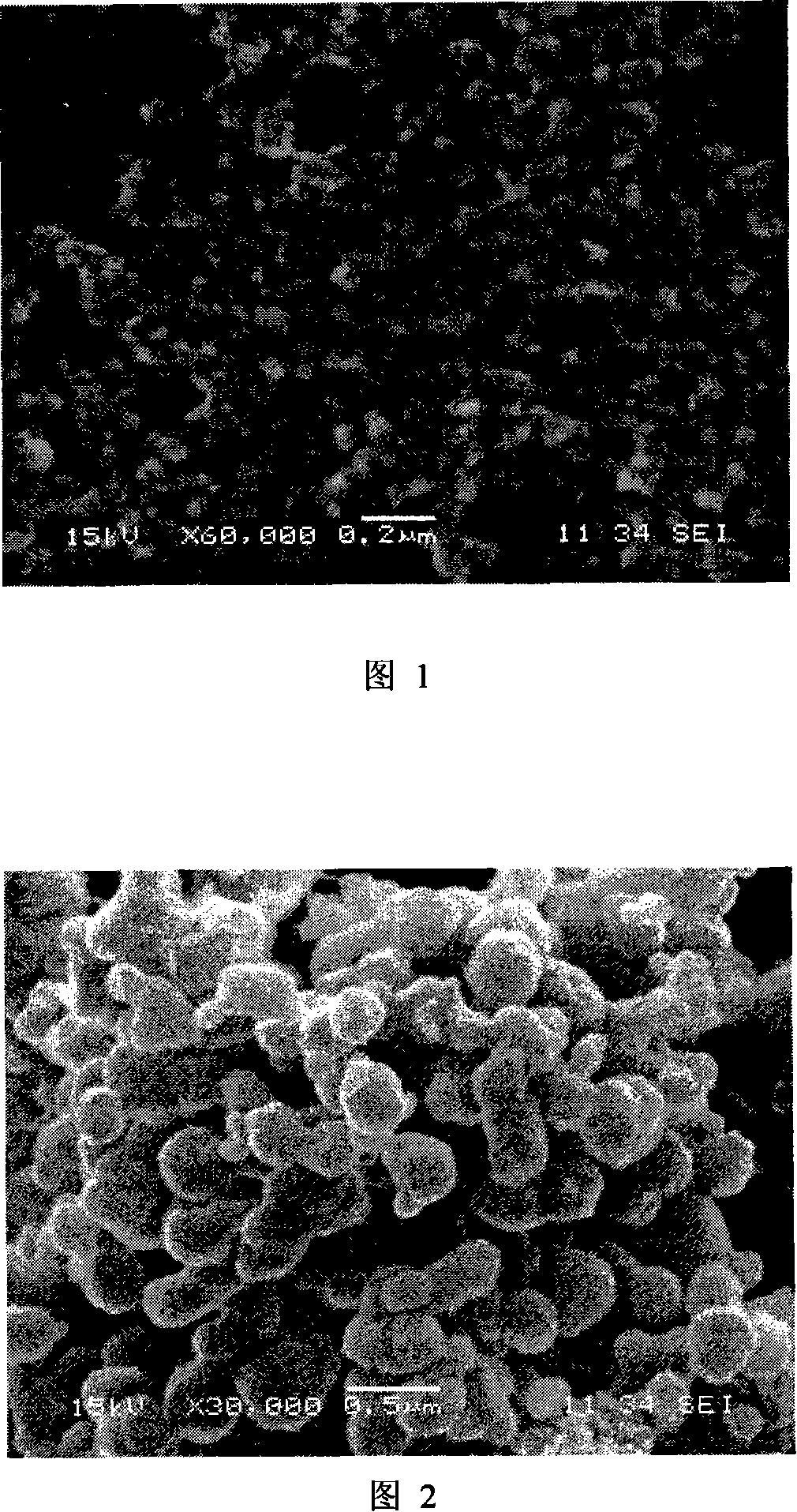

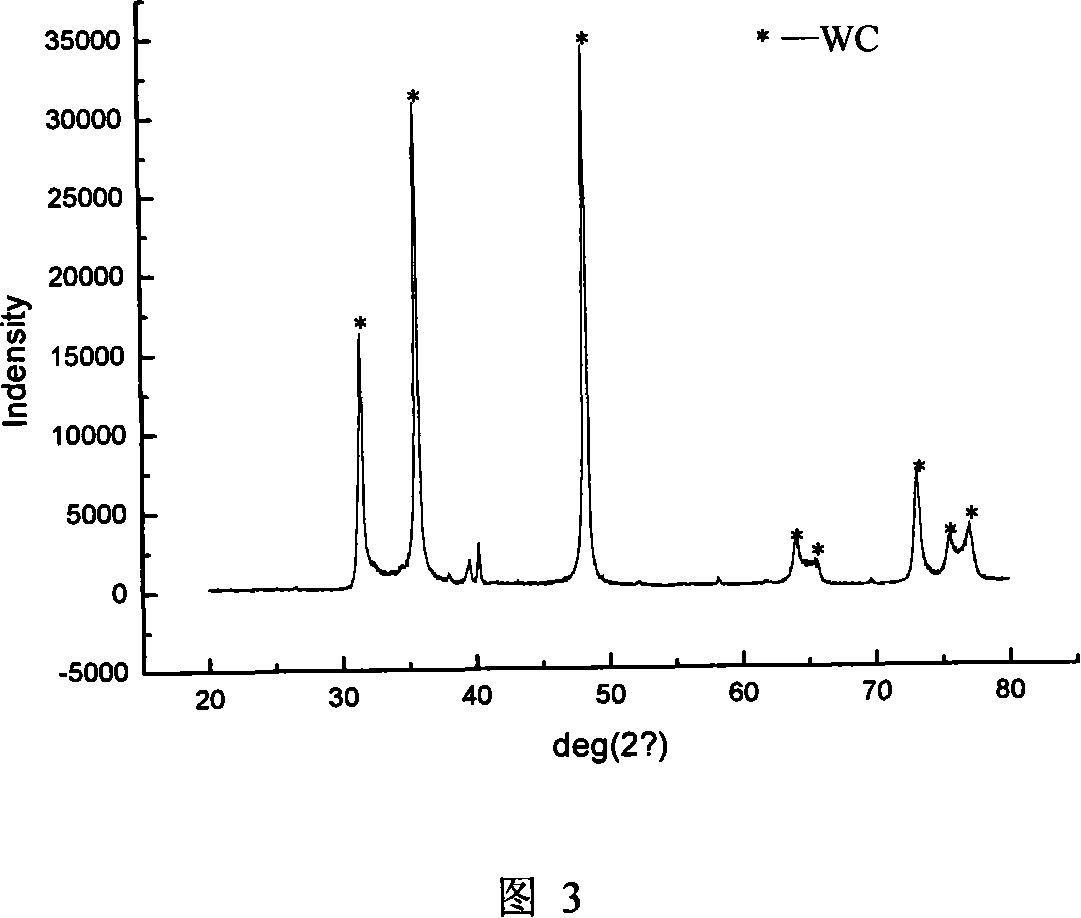

[0011] Example 1: Using activated carbon as a carbon source, WC powder with a particle size of about 80 nm was prepared.

[0012] 1. Weigh the molar ratio of orthotungstic acid and activated carbon to be 1:2;

[0013] 2. Add ammonia water to the orthotungstic acid drop by drop, and keep stirring until the orthotungstic acid is completely dissolved;

[0014] 3. Add activated carbon to the 2 solution, cover with plastic wrap, and let it stand for 7 to 9 hours;

[0015] 4. Filter the solution that has been left standing, take the solid and put it in an oven, and dry it at 80°C for 4 hours;

[0016] 5. Put the dried solid into the filtrate, repeat steps 3 and 4 until the activated carbon absorbs all the liquid;

[0017] 6. Put the dried mixed powder into a tube furnace, keep it warm at 1000°C for 1 hour in a hydrogen atmosphere, and then cool it with the furnace;

[0018] 7. Take out the powder and grind it.

Embodiment 2

[0019] Example 2: Using expanded graphite as a carbon source to prepare WC powder with a particle size of about 200nm

[0020] 1. Weigh the molar ratio of orthotungstic acid and expanded graphite to be 1:2;

[0021] 2. Add ammonia water to the original tungstic acid drop by drop, and keep stirring to dissolve all the original tungstic acid, and add excess ammonia water;

[0022] 3. Add expanded graphite to the 2 solution, cover with plastic wrap, and let stand for 7-9 hours;

[0023] 4. Filter the solution that has been left standing, take the solid and put it in an oven, and dry it at 80°C for 4 hours;

[0024] 5. Put the dried solid into the filtrate, repeat steps 3 and 4 until the expanded graphite absorbs all the liquid;

[0025] 6. Put the dried mixed powder into the tube furnace, keep it warm for 1.5 hours above 1000°C in a hydrogen atmosphere, and then cool it with the furnace;

[0026] 7. Take out the powder and grind it.

Embodiment 3

[0027] Example 3: WC powder was prepared using activated carbon as a carbon source.

[0028] 1. Weigh the molar ratio of orthotungstic acid and activated carbon to be 1:1.5;

[0029] 2. Add ammonia water to the orthotungstic acid drop by drop, and keep stirring until the orthotungstic acid is completely dissolved;

[0030] 3. Add activated carbon to the solution obtained in the above step 2, cover with plastic wrap, and let stand for 7 to 9 hours;

[0031] 4. Filter the solution that has been left standing, take the solid and put it in an oven, and dry it at 80°C;

[0032] 5. Put the dried solid into the filtrate, repeat steps 3 and 4 until the activated carbon absorbs all the liquid;

[0033] 6. Put the dried mixed powder into the tube furnace, keep it warm for 1.5 hours above 1000°C in a hydrogen atmosphere, and then cool it with the furnace;

[0034] 7. Take out the powder and grind it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com